Tomc938

Ultra Member

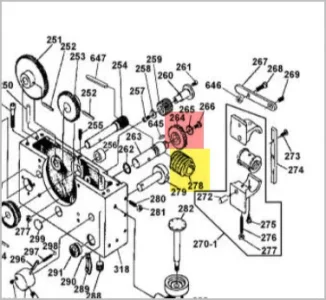

I was wondering about the QC gears. Glad to hear they are still together! That's another 100 pieces I won't have to worry about. I located the service manual for the gear head lathe, and I think the parts numbers max out at around 600. Lots of gears. Some 24 tooth, some 28 tooth, and some 32 tooth. I was wondering if there won be a lot of tooth counting in my evenings going forward.To fill in a bit - Belt drive, not gear head. Serial number indicates 1996. Yes, tailstock in is one of those boxes. You can probably read the labels on some of the boxes if you look close or zoom in. I did not disassemble the QC gear box, and IIRC, the entire apron either. I did not remove the headstock from the bed - I figured there would be enough fiddling without having to think about re-aligning the headstock to the bed. The next step would just be cleanup, and I didn't see that removing the headstock would help enough to be worth the effort.

The fact that it is a belt drive is also a good thing as my other lathe is a King 1236, belt drive. I'm guessing there will be a lot of similarity between the two. As a bonus, I need to replace the belts on my 1236, so putting this one together should go a long ways in helping me disassemble and reassemble things to change the belt.

One thing I am looking forward to is a 2" hole through the spindle. My old Craftex had a 1". Although it seemed to me it was more 62/64" as I could seldom get the 1" stock I wanted through the spindle! I think my 1236 is 1.5".

Picking it up Monday morning. Getting pretty excited!

(PS: I did zoom in and saw that the boxes are labeled (going to be helpful), and the tailstock is there. Bit of a running joke about missing tailstocks here.