The motor may need to be internally rewired for the fwd/rev function.

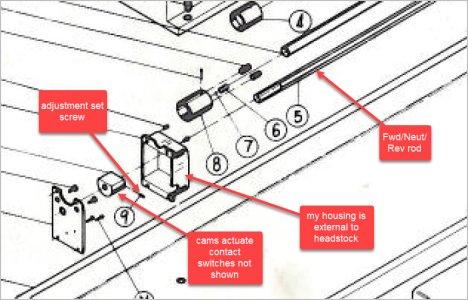

Where is the fwd/rev switch located? I don't see it in the picture.

KMS bought out House of Tools, you could check with them and see if they have any old manuals on file.

A good cleanup and a bit of repair should net you a nice machine.

Congrats.

Where is the fwd/rev switch located? I don't see it in the picture.

KMS bought out House of Tools, you could check with them and see if they have any old manuals on file.

A good cleanup and a bit of repair should net you a nice machine.

Congrats.