Typically what happens around here with a project is they get stalled on some aspect (material, tools, talent....), put aside, and "acclimatize". This one got stalled on the fact that I needed some 1.5" Dia rollers. I didn't have any 1.5" stock, and the thought of turning down my only 2" stock which was either some 17-4, or 4140 didn't really seem like A) a good time, or B) a worthy use of that material for this project C) I had it earmarked for something else......This project not really being a high priority thing that needed finishing, I tucked it out of the way (after moving it a couple times....) and waited until I might stumble into some suitable material, or needed to make a trip to the metal store for something else. Fast forward a couple months to Monday night when during my habitual marketplace browsing I stumbled on an ad for some 1.5" bar, a 3/4" bar, and some 1/8" plate for $20. The kicker, it was literally right down the road, and posted by an old acquaintance. After a good visit of catching up last night while picking it up, I bumped this project back up the list to finish it off.

The haul

I took the two side plates and lined up the bottoms and on of the tabs with some setup blocks, then tack them together.

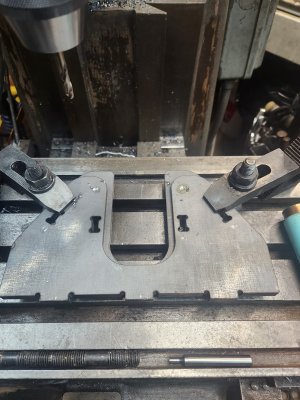

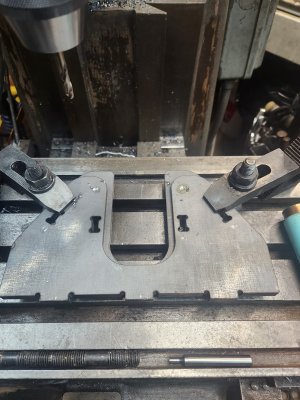

Then clamped them down to the mill table on some parallels, edge found the bottom, and middle of the slot and then proceeded to drill and ream them to 0.501" based on the locations from the design.

I ground the tacks holding them together off, and Next was to cut some 1/2" pins, and fit it all together with some 123 blocks to keep it square. The pins fit perfectly with a nice slip fit. Lets hope they stay that way after welding......

I tacked it all together, removed the clamps and 123 blocks, then welded all the tabs up. When I designed this, I left the tab ends short 1/16", hoping the plug weld would fill the gap, and I could grind it flat for a nice finish. If I were to do this again, I would only leave 1/32. I could go back and fill them up a bit more with weld, but I'm not bothered that much by it. For my first tab and slot design, it's a learning point (there's been a few so far...). I also didn't want to weld too much to fill them up for fear of twisting it all up like a pretzel. After all was said and done, the pins fit perfectly, and the base was still nice and flat. It didn't twist at all. I like this method of design.....will use again in the future.

Having now ground all the welds flat, I cut some 1.5" shaft up to make the rollers, and punch.

Into the lathe to face the end, then drill and ream for 0.501". Not exactly sure what material this was, but it came from a Millwright/farm repair shop. I never bothered to do a spark test, or anything aside from a quick file test to make sure it wasn't hardened. I don't think it's just mild steel based on the way it cut but I'll do some more testing on it some other time though. Would be nice to know for more critical projects. This one is not, I didn't even bother to turn the od, just cleaned up with a stripping disc to get the rust off.....

Rollers done it was time to finish the cross pins. I turned a groove for a clip on one side, then welded a washer on the other. Here it is all assembled.

https://i.imgur.com/wajlm0C.mp4

https://i.imgur.com/wajlm0C.mp4

That's it for now. Need to make the punch side, then start cutting up some coupons to practice welding. Back when I started I'd set a goal of July for myself to get my certs......best I can say is life got in the way......Still need to make a positioner arm next, then get to practicing.