Hard to know but that could have contributed to some challenges. Was the part pretty hot at any time of milling? Your chips don't look discolored inferring no but not sure if that was cleanup operation.

I haven't done a ton of SS but I prefer 303 hands down over 304. For some reason the local places unfortunately seem to predominantly carry 304. If its just some basic turning, fine, we can usually slog through it. But personally, if its a more complex part, especially tapping or threading, I find myself passing on the Mysterium scrap box because, time, power & broken tools cost money too LOL.

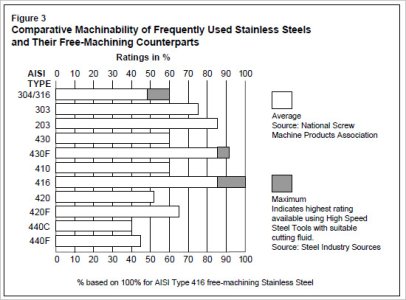

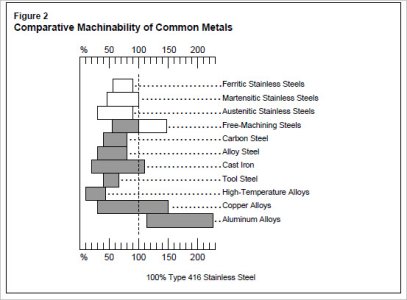

Note Fig-2 that compares SS to other alloys is based on the best SS machineability as reference (416). All other SS's are lower (Fig 3).

I haven't done a ton of SS but I prefer 303 hands down over 304. For some reason the local places unfortunately seem to predominantly carry 304. If its just some basic turning, fine, we can usually slog through it. But personally, if its a more complex part, especially tapping or threading, I find myself passing on the Mysterium scrap box because, time, power & broken tools cost money too LOL.

Note Fig-2 that compares SS to other alloys is based on the best SS machineability as reference (416). All other SS's are lower (Fig 3).

Attachments

Last edited: