I haven't went to Metal pros yet I saw they were selling "lots" of cutoffs but I prefer to rummage as well, the prices are crazy. I went a couple of times to MSM in Hamilton last fall and surprisingly we got to rummage in the back and I thought the price for cutoffs was cheaper but I didn't get a receipt last time to compare in Ottawa.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finally got a lathe!

- Thread starter TimDubois

- Start date

Well I finally got started turning my pieces. Unfortunately I didn't get that far because my boring bar won't fit in a 1/2" hole and since the move I have no idea where my reduced shank twist drill are. I'll have to pick up a drill tomorrow.

On a positive note the accusize tools seem to work very well on aluminum with the ccgt carbides.

On a positive note the accusize tools seem to work very well on aluminum with the ccgt carbides.

140mower

Don

Yup, it's a twist drill today, a reamer tomorrow, who knows what next week..... 'tis a slippery slope ahead. 😵So it begins! View attachment 21387

Does the CHMW have a supplier database that lists suppliers based on geographical area ?

It might be a handy database to maintain for the membership, especially since the recent shortage of inventory that most outlets are currently experiencing in 2022.

It might be a handy database to maintain for the membership, especially since the recent shortage of inventory that most outlets are currently experiencing in 2022.

deleted_user

Super User

This would be excellent part of a broader suppliers directory...Does the CHMW have a supplier database that lists suppliers based on geographical area ?

It might be a handy database to maintain for the membership, especially since the recent shortage of inventory that most outlets are currently experiencing in 2022.

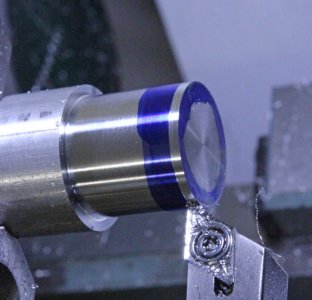

Finally got the first hub turned down. Was slower going than im used to with the colchester I used to have at work but the Atlas performed great.

I got a little chatter on the final pass of the first bearing seat. The carbides don't like taking sub thou cuts apparently. Sorted it out on the second bearing seat by making sure my finish pass and the pass before it were the same DOC.

Everything fits as it should, now I just need to do it again.

I got a little chatter on the final pass of the first bearing seat. The carbides don't like taking sub thou cuts apparently. Sorted it out on the second bearing seat by making sure my finish pass and the pass before it were the same DOC.

Everything fits as it should, now I just need to do it again.

I'm very happy with this DCMT insert on aluminum. You can maybe make out swarf curl off to the side. If I recall this is 0.0005" DOC on the piston crown. I could probably do better if my lathe had finer feed.

I think its a 0.4mm nose radius. Uncoated, extremely sharp, I believe Korloy via Ebay seller. Not expensive. You can also get larger nose radius in the same style & multitude of holders to hold at different orientations.

I think its a 0.4mm nose radius. Uncoated, extremely sharp, I believe Korloy via Ebay seller. Not expensive. You can also get larger nose radius in the same style & multitude of holders to hold at different orientations.

Attachments

The hubs are a custom design of mine for my Terra Jet. It's not really a Terra Jet anymore but it's based off that platform.

The locking hubs are for a K2000 pickup if I remember correctly. I just found a stock locking hub in the overall size I was looking for and designed everything else to fit.

The locking hubs are for a K2000 pickup if I remember correctly. I just found a stock locking hub in the overall size I was looking for and designed everything else to fit.

It weiged in at 880lbs last time I checked but its also not completely done so there's more weight to go on it. It should still be under 1000lbs when it's completed.

The tub is 1/8" 6061 aluminum and the frame 3/16" thick 2 1/2" square tubing.

The terra jets originally came in 3 different styles two were 4x4 of which one had a steel body and the other fiberglass and the last model was a 6x6 beast.

The tub is 1/8" 6061 aluminum and the frame 3/16" thick 2 1/2" square tubing.

The terra jets originally came in 3 different styles two were 4x4 of which one had a steel body and the other fiberglass and the last model was a 6x6 beast.

The 6x6 Argos were able to travel in calm water because the tires were floatation style and the fibreglass bodies were sealed similar to a small boat.

They had a coordinated steering by driving opposite wheels.

What does the TerraJet have for a motor ?

They had a coordinated steering by driving opposite wheels.

What does the TerraJet have for a motor ?

I got a little chatter on the final pass of the first bearing seat. The carbides don't like taking sub thou cuts apparently. Sorted it out on the second bearing seat

HSS for tight tolerance finish cuts on aluminium. Much sharper for wisp cuts. Toyota hubs?

I'm on the same page as Darren.

Ya, you can make carbide work. But sharp HSS works every time all the time. It's a no brainer. If you have to sneak up on a dimension, why take chances? Just use what you know for sure will work.

The 6x6 Argos were able to travel in calm water because the tires were floatation style and the fibreglass bodies were sealed similar to a small boat.

They had a coordinated steering by driving opposite wheels.

What does the TerraJet have for a motor ?

My Terra Jet has a 16Hp Vanguard V twin at the moment.