little ol' e

Jus' a hobby guy

Just about out of time here today. I will try to post something from amazon. I'm not a user of these but will give you a good idea.

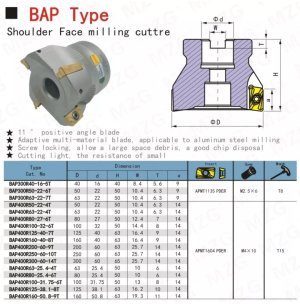

Although these types of high feed cutters are not really meant for facing, you could, but you just need to keep in mind of what stepover you will need to take depending on what diameter you choose. Then watch for steps between stepovers depending on how good your mill is squared up.

This style is,

Excellent for roughing, semi finishing, and finishing over the square and or rectangle inserts. They have a good chip breaker as well depending on how much $ you want to spend on inserts.

I would start off on the cheap, little chip breaker, cheaper coating, ( ali perhaps ) then step up once you get comfortable with these types of inserts, coatings and chip breaker styles.

You will be sizing walls with an endmill anyway in most cases, so the need for square corner inserts are really of no benefit these days IMHO.

Plus, these style inserts will last much longer, take more abuse, while keeping the heat at a minimum while your figuring out your speeds and feeds for your mill.

Hope this helps some!

Although these types of high feed cutters are not really meant for facing, you could, but you just need to keep in mind of what stepover you will need to take depending on what diameter you choose. Then watch for steps between stepovers depending on how good your mill is squared up.

This style is,

Excellent for roughing, semi finishing, and finishing over the square and or rectangle inserts. They have a good chip breaker as well depending on how much $ you want to spend on inserts.

I would start off on the cheap, little chip breaker, cheaper coating, ( ali perhaps ) then step up once you get comfortable with these types of inserts, coatings and chip breaker styles.

You will be sizing walls with an endmill anyway in most cases, so the need for square corner inserts are really of no benefit these days IMHO.

Plus, these style inserts will last much longer, take more abuse, while keeping the heat at a minimum while your figuring out your speeds and feeds for your mill.

Hope this helps some!

Last edited: