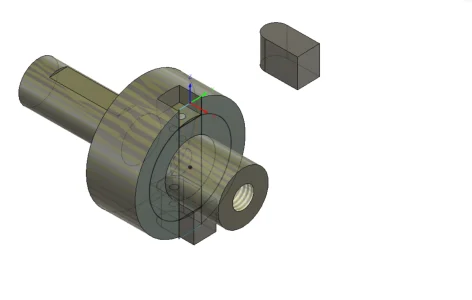

I have a 100mm ( 3.9") diameter face mill but the holder for it is R8. I need CAT40. After going back and forth with China it was going to be over $100 including shipping so I decided I'd make an adapter to work with my 1" Cat 40 tool holder. Here is the CAD and some build photos. I started with 3" hot roll.

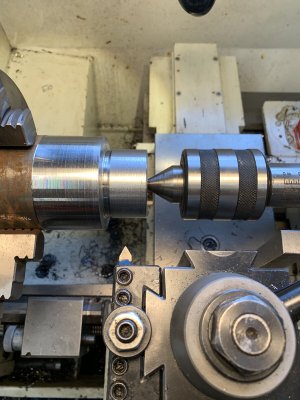

I managed to hit 0.998" diameter for the top end. I needed just less than 1.000". The adapter fits into the cat40 1" tool holder well. This is the second go at the adapter as I made the first one too small.

After milling dog slots, drilling holes, and flats for the set screws.

I managed to hit 0.998" diameter for the top end. I needed just less than 1.000". The adapter fits into the cat40 1" tool holder well. This is the second go at the adapter as I made the first one too small.

After milling dog slots, drilling holes, and flats for the set screws.

Last edited: