-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enterprise 1550 Rebuild

- Thread starter Sailor

- Start date

I did find out that the original makers of this lathe shut the plant in the early 2000 because of labour disputes. Some of the workers and engineers have recently started their own plant and are making a very similar lathe under a different name. I may be getting a contact soon.

Thanks to Tom for showing me a thread from Practical Machinist.

Thanks to Tom for showing me a thread from Practical Machinist.

Last edited:

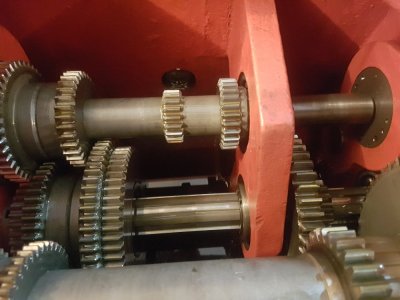

I thought I had a couple really good snap ring sets but this was challenging, I could not reach in against the wall and on one it was hard to open it wide enough and get something in behind it. Another person would have been nice but with this COVID and our circle of friend's ages we're on our own. I'm sure many of you are feeling it too. There was no metal filings in any of the gear boxes. I did place ceramic magnets in all before reassembly and closing.

Last edited:

That's a really nice looking lathe. Looks like it hasn't been broken in yet. Sometimes it's better to slip the snap ring to a nearly stupid location, to get the clearance to undo it... I'm sure you've tried everything, though.

-- One last resort on one machine was to score the back of the snap ring with a dremel (mind the abrasive dust) and break it, and replace it with new. There wasn't any space between the gears to use any kind of snap ring pliers. An assemble-only fixture!

-- One last resort on one machine was to score the back of the snap ring with a dremel (mind the abrasive dust) and break it, and replace it with new. There wasn't any space between the gears to use any kind of snap ring pliers. An assemble-only fixture!

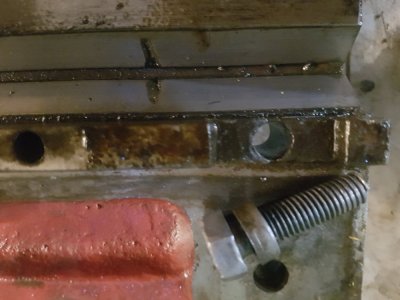

A few more broken and missing parts. PeterT helped me a lot with my broken bolt on the apron. Turns out the missing part it screwed into was a stop block for the apron. Some brass ball oilers were damaged and a couple bearings on cross slide where it attaches to the taper. A spring behind this lever was damaged and the 6mm ball missing. I’ve sourced these parts and just waiting.

Attachments

There might be some oiler fittings floating around members here who have also had to replace theirs. They appear on Ebay & Ali, but with some variations. They aren't too onerous to obtain but sometimes longer shipping time & variable quality. I think the barrel OD is usually metric but with Asian machines, seems like anything goes. I've seen some better looking (what I suspect are actually grease fittings) but I think same type of ball & spring mechanism would work for oil but often they protruded a bit too much so may or may not work depending if the originals are more flush mount for clearance reasons.

I bought a bunch of ball oilers on Amazon. They came from Russia, took about a month to get here.

https://www.amazon.ca/Maslin-Quality-Button-Engine-Billiard/dp/B07KJDQY6H

https://www.amazon.ca/Maslin-Quality-Button-Engine-Billiard/dp/B07KJDQY6H

Some rust on ways and cranks. So far polished to 2000 grit wet. I’m rubber coating some handles and gun metal on the cranks....I think. See how it goes. Original handles had a plastic coating. I have been using this spray oil as I polish and it leaves the slickest film and really dissolved the rust . . . https://www.princessauto.com/en/detail/fluid-film-penetrant-and-lubricant/A-p6420392e

Attachments

Last edited:

https://www.gitsmfg.com/metric-ball-valve-oilers/

https://www.precisionmatthews.com/shop/balloiler8mm/

Good selection of ball oilers here as well. I ordered some from here as well to see which come closest to the originals. Mine are 8 mm.

https://www.precisionmatthews.com/shop/balloiler8mm/

Good selection of ball oilers here as well. I ordered some from here as well to see which come closest to the originals. Mine are 8 mm.

Yup, those are the oilers. The ones on my (Taiwan) machine are ok but still prone to the ball sticking. Not related to injesting swarf or dirt, I think because the can & lip is kind of thin & fragile. Might also be related to how they were installed, like distorted a bit. The Chinese ones seemed just a smidge lower quality yet. There is a Stefan video where he replaced his with some better quality 'red ball' euro ones. I found the source but wasn't easy to get them due to their weird payment system. Probably if you search on 'oiler' here on forum you'll get the story.

I also bought one of these Goldenrod oil cans and the tip is perfect for the ball oilers.

https://www.amazon.ca/GOLDENROD-707-Industrial-Oiler-Spout/dp/B00004YK76/ref=sr_1_4?crid=3NAOCOQ27LGB3&dchild=1&keywords=goldenrod+oiler&qid=1605378678&sprefix=goldenrod,aps,205&sr=8-4

I use Fluid Film too, great stuff. I coat all my bare metal stuff with it to prevent rust.

https://www.amazon.ca/GOLDENROD-707-Industrial-Oiler-Spout/dp/B00004YK76/ref=sr_1_4?crid=3NAOCOQ27LGB3&dchild=1&keywords=goldenrod+oiler&qid=1605378678&sprefix=goldenrod,aps,205&sr=8-4

I use Fluid Film too, great stuff. I coat all my bare metal stuff with it to prevent rust.

Last edited:

Yes, I have two golden rods for my other lathe, they have just the right tip for ball oilers. One has a straight nozzle for oilers on the side and the other is bent for top oilers. I used to use another kind and actually heard about these oilers on Blondie hacks?? site. Cant remember. I super appreciate everyone's input, a great bunch, I hope I will add a little as time goes by. I will look into those other oilers PeterT. Found some, will keep looking. https://www.mafa-shop.com/shop/en/b...h-for-press-fitting?number=A096010&c=99700488

Last edited:

Looks like you know your way around machines but FYI some of my lathe oil passages were plugged off. Some had what I think was the preservative wax in there. It wasn't old or stagnant oil because the other passages were clean. One passage was an incomplete drill connection between 2 right angle holes so unfortunately the target parts were never getting lube from day one. When you have everything disassembled, its an opportune time to check for this with some fluid. I found WD40 or some mild thinner softened the waxy mung. I used a squeeze bottle to inject the solvent with a bit of pressure it & sure enough a turd residue plug came out. The passages on my apron make a few right angle turns & then down to the apron gears. I think more sophisticated lathes, especially if they have apron oil bath may not be this way.

Lots of cleaning. Using PeterT’s suggestion to clean out oil passages. More cleaning. Amazes me where metal filing can gravitate to. And I need to gravitate to bed.