-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DRO

- Thread starter Michel T

- Start date

1018Machine

Super User

For what I do the measurement on the quill is important so three minimum. That said I actually went with a four axis for my latest mill as I wanted control of the knee position as well.

ChazzC

Ultra Member

Please provide more details (since you’re a new member you won’t be able to add photos yet) of the “small mill:” small mill or mini-mill is used by folks to describe anything including Sherline/Taig Mills, SIEG Mini-Mills, Bench Mills or Round Column Mill-Drills. Manufacturer & model number will help greatly.

Dan Dubeau

Ultra Member

I've never used a mill with a readout on the Z (except CNC). It sure would be nice. I do have a quill readout, but having an actual scale on the knee would be awesome. Starting from zero with nothing, I would spring for as much as you can stomach buying. I'm not sure if the any of the imports now can coordinate the scale and do additive/subtractive math, but I've seen that before when there are two scales for the Z Knee/quill. Seems like a pretty handy feature, and might be something to look for.

Personally, I'd get a 4 axis and configure it to add the quill and head/knee to get total Z. You can also get RPM. That's what I did and I'm very happy with it.

The readout is only marginally more expensive that way, so the main cost difference is the additional scales.

Or you can start with the readout and add scales as you find that you need them.

The readout is only marginally more expensive that way, so the main cost difference is the additional scales.

Or you can start with the readout and add scales as you find that you need them.

Thanks for the comments, I thonk I will spring for the 3 axis unit. Other question, I also have a lathe next to the mill. Would anybody know if it would be possible to use the same readout unit to read scales installed on the lathe ? I would obviously have a switch arrangement to switch the scale connections between lathe and mill . Any comments appreciated.... THX !

Would anybody know if it would be possible to use the same readout unit to read scales installed on the lathe ? I would obviously have a switch arrangement to switch the scale connections between lathe and mill . Any comments appreciated.... THX !

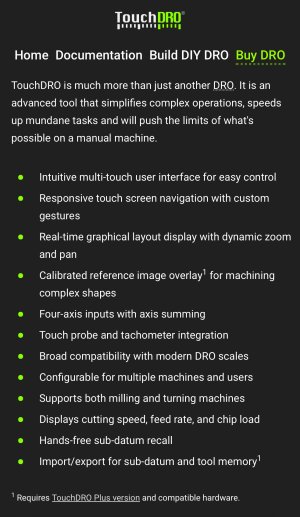

It is well worth considering a touch dro at that point. The screen can be common. In fact, they are worth considering even with just one machine.

Lots of our members have them and love them. Especially now that the developer has solved the Samsung display problem.

Here is the Touch Dro web site:

Also search on "touch" here to get a feeling for how members like them.

TouchDRO - Modern Touchscreen DRO for Lathes and Milling Machines

TouchDRO is a touchscreen digital readout (DRO) for machine shop hobbyists, offering professional grade features, unmatched flexibility, and ease of use.

www.touchdro.com

Also search on "touch" here to get a feeling for how members like them.

ChazzC

Ultra Member

Thanks. It being a bench mill and assuming similar to this (couldn't find any photos of a 1976):It's a bench mill Craftex 1976

there are three axes: X-, Y- & Z- (with the Z- having a coarse & fine feed): I would go with a 3-axis setup.

If the model you have is more like the newer Craftex Bench Mills:

you could just go with X- & Y- and rely on the built-in readout for the quill, but I would at least add Z- for the head movement as noted above (referencing the knee). I personally would also replace the readout on the quill with a scale and use the DRO readout to sum the two Z- axes. [here is a thread on H-M on doing an install on the above machine]

And yes, IMO TouchDRO is the way to go, regardless of the scales you use.

Last edited:

trlvn

Ultra Member

I know people like Touch DRO but it is not an inexpensive solution. Especially if you're not invested in the Android ecosystem and have to buy a tablet. Plus, the OP has an older machine. If he decides to replace it, I think it would be tough to recoup the DRO investment.

AliExpress has lots of DRO options. Super cheap LED displays with magnetic scales. Or slightly less inexpensive LCD displays and/or with glass scales. I needed to replace the DRO on my round-column. Details of the new system start at:

Overall I'm pretty happy with the new DRO although I never did find a setting to change from n.nnnnn display to n.nnnn. The final digit of precision is an annoying fairy tale!

OTOH, international trade is in turmoil and tariffs may affect ANY purchase.

Craig

AliExpress has lots of DRO options. Super cheap LED displays with magnetic scales. Or slightly less inexpensive LCD displays and/or with glass scales. I needed to replace the DRO on my round-column. Details of the new system start at:

To close out this thread, I have just finished replacing the DRO on my RF-30 style mill. To recap, the X axis on my old DRO regularly made a clicking sound and that sometimes seemed to cause the display to jump 15-20 thous. After taking the read head off, I could no longer get it to work at all. Still have no idea what went so badly wrong. I decided to buy a new, modern DRO.

I looked at Aikron, Ditron and Sino. Reviewed past threads and info on the Touch DRO site and decided that I wanted glass scales. Decided that there was enough room so that I didn't need Slim or Xtra-slim...

I looked at Aikron, Ditron and Sino. Reviewed past threads and info on the Touch DRO site and decided that I wanted glass scales. Decided that there was enough room so that I didn't need Slim or Xtra-slim...

Overall I'm pretty happy with the new DRO although I never did find a setting to change from n.nnnnn display to n.nnnn. The final digit of precision is an annoying fairy tale!

OTOH, international trade is in turmoil and tariffs may affect ANY purchase.

Craig

ChazzC

Ultra Member

I know people like Touch DRO but it is not an inexpensive solution. Especially if you're not invested in the Android ecosystem and have to buy a tablet. Plus, the OP has an older machine. If he decides to replace it, I think it would be tough to recoup the DRO investment.

I am a fan of TouchDRO and strongly feel that it is equally applicable to older/smaller machines as newer/larger/more professional machines. There are a lot of features that I don't believe can be found elsewhere.

My lathe & mill implementations of TouchDRO are both running Fire Tablets, so don't have the same issues as Android/Google, although I haven't run into any issues with the Fire platform.

One of the biggest advantages of TouchDRO is support: Yuriy responds to all emails and posts on his Hobby-Machinist sub-forum, and his interested in helping his customers.

While Yuriy is in the U.S. and he does use imported components that will (could, who knows) be impacted, final assembly, software development, etc. will only impact whatever costs are involved in getting his component into Canada.OTOH, international trade is in turmoil and tariffs may affect ANY purchase.

Craig

slow-poke

Ultra Member

Personally I would get an AliExpress setup, with magnetic scales. Seems like there are a lot of touchdro fans, I'm not one of them.

A circuit to switch multiple scales to one display is fairly trivial, could be done with a ganged rotary switch no electronics required. That being said for the cost of another display I would just get a second display.

A circuit to switch multiple scales to one display is fairly trivial, could be done with a ganged rotary switch no electronics required. That being said for the cost of another display I would just get a second display.

Any comments appreciated.... THX!

I guess you don't need to search touch after all..... Seems folks weighed in right here......LOL!

Full disclosure - I have a Ditron w magnetic scales system purchased on Ali. But I don't have a favorite. I think they all deliver similar results. Even the much simpler i-Gaging systems work for their intended purpose but as far as I know i-Gaging doesn't offer the cool features of the other systems like bolt circles, arrays, axis adding, etc. etc. Most of us would consider the i-Gaging a low cost low performance option. But that has its place for many of us.

Truthfully, the bigger issues is what scales: glass or magnetic and full size or slim? Don't let the web hub-bub about glass vs magnetic bother you. The only question is cost and mounting space. The rest is noise.

I agree with both @slow-poke & @YYCHM. Those switch boxes are cheap and easy to find. Just make sure they come with all 9 wires or at least have the contacts available so you can add all the wires.

There are a lot of features that I don't believe can be found elsewhere.

Please give me an example Charlie. I have looked and can't find any features that are not in all the other good systems.

I think they all just copy each other.

I haven't kept up with the magnetic vs glass scale cost/benefit discussions, my scales are glass and (knock on wood) have been working well for the last 10 years or so. As for sharing a common display, this is my opinion so take it for what its worth. You have 2 separate machines, don't tie them down with a single display. Imagine making a part on the mill and botch a hole and then need to make an press fit plug for it (never happened to me 🙄). Switch over to the lathe. OK - what happens to your offsets for the mill? Often mill "zero"(x,y and z) is not machine zero but work coordinate zero)? Maybe touch DRO can save them, but that is yet another learning activity for a function that can be skipped if you have 2 displays.

ChazzC

Ultra Member

How many have the capability to import models so you can locate points?Please give me an example Charlie. I have looked and can't find any features that are not in all the other good systems.

I think they all just copy each other.

Do the AliE units include a graphical presentation?

TouchDRO - Modern Touchscreen DRO for Lathes and Milling Machines

TouchDRO is a touchscreen digital readout (DRO) for machine shop hobbyists, offering professional grade features, unmatched flexibility, and ease of use.

www.touchdro.com