gerritv

Gerrit

If you have attached your QCTP as Robin or Stefan have done (it can't rotate) then drilling, tapping and die threading using the carriage is superior in my opinion. I no longer have to wind the carriage out of the way from the tail stock, I can easiliy sap between drill chuck and tap/die holders. And then there is peck drilling, either with an ELS (in my case) or by hand. Lastly, for large holes it is simple to switch to boring tools after drilling a start hole.

With my DRO I dial in the tool holder once, and then select it (SDM #3 🙂 and align it to 0.

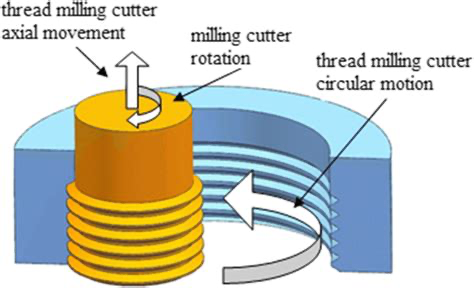

Bonus is DRO works on the Z axis. Another bonus, you can thread mill using the carriage.

My lathe is a 1022 and I don't have MT drills.

With my DRO I dial in the tool holder once, and then select it (SDM #3 🙂 and align it to 0.

Bonus is DRO works on the Z axis. Another bonus, you can thread mill using the carriage.

My lathe is a 1022 and I don't have MT drills.