As some of you may know, I'm (trying) to build my own lathe. Size is approximately the same as the LMS 6500 or the M1111 (roughly an SX2.7)

I have the motors and most of the electronics as well as the LMS column and the M1111 table. will send photos and specs as a follow-up.

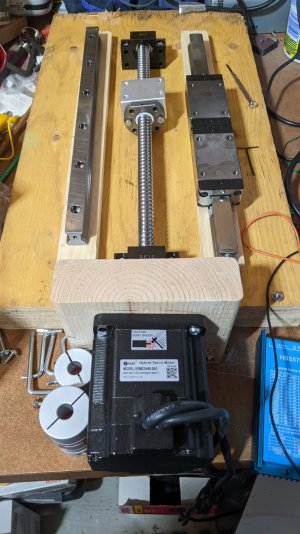

What I am struggling with is how (and where) to but the base together. Initially I thought I'd use the LMS base but decided against that because I would like some extra travel for the table that is a little larger than the LMS one. The thought now is to use a 10" x 22" steel plate about 1/2 to 1" thick and have that sandblasted or similar. Weld or bolt two 10mm x 1" x 20" steel bars onto that and have those precision machined to accommodate the linear rails that I plan on using. Attached is a working wooden model of the concept.

I'll send more pictures once I figure out how to reduce the size.

Any suggestions and or warnings on this approach welcome.

Would also appreciate suggestions as to which machine shop in the Peel, Halton or Hamilton area would be a potential manufacturer as I don't have a mill or a welder.

I have the motors and most of the electronics as well as the LMS column and the M1111 table. will send photos and specs as a follow-up.

What I am struggling with is how (and where) to but the base together. Initially I thought I'd use the LMS base but decided against that because I would like some extra travel for the table that is a little larger than the LMS one. The thought now is to use a 10" x 22" steel plate about 1/2 to 1" thick and have that sandblasted or similar. Weld or bolt two 10mm x 1" x 20" steel bars onto that and have those precision machined to accommodate the linear rails that I plan on using. Attached is a working wooden model of the concept.

I'll send more pictures once I figure out how to reduce the size.

Any suggestions and or warnings on this approach welcome.

Would also appreciate suggestions as to which machine shop in the Peel, Halton or Hamilton area would be a potential manufacturer as I don't have a mill or a welder.