-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

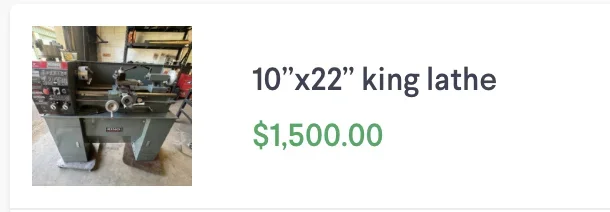

Diamond in the rough.

- Thread starter PatrickT

- Start date

Proxule

Ultra Member

The first mod I did to my lathe, and likely the best one!perhaps even a VFD for this gem.

You will not regret the time or money!

Proxule

Ultra Member

I never seen those particular brand, But my turbine experience has all been gas and steam turbines. Last one was for esso/imp oil here in Edmonton that took their hydrogen gas ( instead of flaring off ) and made power to be sold / fed back to Edmonton grid.Japanese KW bearings, which he's seen on turbine engines

What an awesome deal on this lathe!!

Congratulations!

PatrickT

Well-Known Member

I’ve worked on n Rolls Royce turbines on offshore platforms, never seen them either. I dug up some info on them, the Kumara factory apparently specialized in aerospace bearings for NTN, and the previous owner of the lathe made parts for landing gear out in Waterloo, so they may have been installed by him from his own supply.I never seen those particular brand, But my turbine experience has all been gas and steam turbines. Last one was for esso/imp oil here in Edmonton that took their hydrogen gas ( instead of flaring off ) and made power to be sold / fed back to Edmonton grid.

What an awesome deal on this lathe!!

Congratulations!

Proxule

Ultra Member

Fascinating, thanks !I’ve worked on n Rolls Royce turbines on offshore platforms, never seen them either. I dug up some info on them, the Kumara factory apparently specialized in aerospace bearings for NTN, and the previous owner of the lathe made parts for landing gear out in Waterloo, so they may have been installed by him from his own supply.

PatrickT

Well-Known Member

I'd like to pick your brain about VFD's for this lathe before I grab a 3-Phase converter for a 240V hookup. Any inside appreciated. Lathe is currently 230V 3 Phase 3HP 1800 rpm I believe.The first mod I did to my lathe, and likely the best one!

You will not regret the time or money!

I'd like to pick your brain about VFD's for this lathe before I grab a 3-Phase converter for a 240V hookup. Any inside appreciated. Lathe is currently 230V 3 Phase 3HP 1800 rpm I believe.

You are a lucky man. That will be one of the easiest VFD installations ever.

Hey Patrick, if you're interested, I have 4 Hitachi VFD's controlling the motors on my machines. You are more than welcome to come check it out first hand. With brake resistors on two of them.

PatrickT

Well-Known Member

I'm more interested in your B&S & Mk2, but yeah! I have so many questions, I'll bring coffee!Hey Patrick, if you're interested, I have 4 Hitachi VFD's controlling the motors on my machines. You are more than welcome to come check it out first hand. With brake resistors on two of them.

Ok, great. I will send you a PM with my address.I'm more interested in your B&S & Mk2, but yeah! I have so many questions, I'll bring coffee!

Proxule

Ultra Member

Seems thestlster has you covered, But I would say all the hard work is done by having that 3 phase motor all ready there.I'd like to pick your brain about VFD's for this lathe before I grab a 3-Phase converter for a 240V hookup. Any inside appreciated. Lathe is currently 230V 3 Phase 3HP 1800 rpm I believe.

I opted for a vector speed control VFD, As it provides the most torque at low RPM.

But honestly you can get away with any old plain VFD. I have been running 3 aliexpress special VFD's now for several years,

One failed - turned out to be a filter capacitor, Replaced the SMD capacitor, No issues since.

YMMV - Gluck

PatrickT

Well-Known Member

Attachments

PatrickT

Well-Known Member

I literally couldn't help myself. On a side note, The guy who sold this to me, a welder and part time hobby machinist, bought a whole shop off a train maker in Burlington, including the most meticulously maintained Milford table top mill, with machined 3-axis levelling blocks and literally thousands of pieces of tooling. This was the train makers King mill, and if you look closely, you can see about a dozen precision mods he's done to it. The lift I got for $250 off a teacher at one of the colleges in Guelph, who said "give it a good home, I don't need it, the kids wouldn't know how to use it these days", lol.You should probably buy a lottery ticket since you're on a roll. But if you notice lightning clouds in the distance maybe consider a cool off quarantine period. Let the universe revert to equilibrium.

Yes, I'm taking a break, but 15 minutes of scanning the classifieds has probably saved me enough cash to cover my full shop Reno, so that's not stopping anytime soon.

Attachments

Dam, you maybe better start complaining about something wrong with a piece of equipment. That is very lucky with good timing and money at hand. Everyone is going to be hanging around with you just for the cast offs you don't want that you find!

Just make sure the wind isn't back filling the sails!

Just make sure the wind isn't back filling the sails!

PatrickT

Well-Known Member

Oh fear not, I'll be posting finds here to fill up the shop tool Karma Bank! I have a nice list going; Myford's, Colchester's, Hardinge etc.Dam, you maybe better start complaining about something wrong with a piece of equipment. That is very lucky with good timing and money at hand. Everyone is going to be hanging around with you just for the cast offs you don't want that you find!

Just make sure the wind isn't back filling the sails!

The only complaint I have so far, is trying to find a good drop deck trailer in Ontario is next to impossible under $8k; anything less has no load rating.

The only complaint I have so far, is trying to find a good drop deck trailer in Ontario is next to impossible under $8k; anything less has no load rating.

You can borrow mine, but I'll keep an eye open for you.