Love this idea. Let me noodle on it.Does anyone use a snap-in, pinned or other type of quick release attachment method for the scales?

As I understand it, getting it into the exact same place when it’s installed or replaced Isn’t critical, but it needs to be locked in and not move once it is in place.

A quick release latch might allow for easy gib maintenance, oiling, or even follow rest usage etc.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

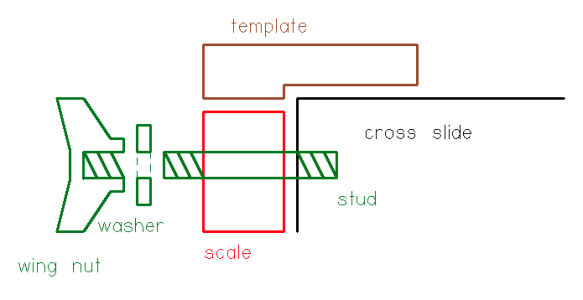

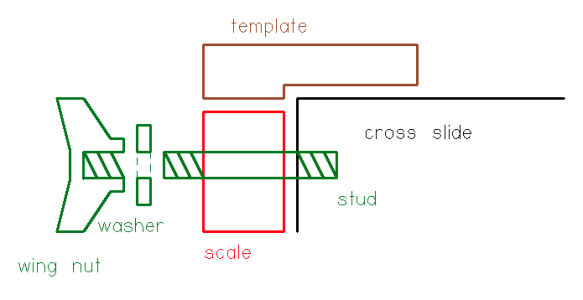

Shouldn't be all that tricky. A couple of studs into the cross slide, washers and wing nuts. The critical detail is that the scale is parallel to movement of the cross slide, and that could be as simple as a nice steel template to check alignment between the scale and the slide. Adjust both ends of the scale to be true to the cross slide and you're done, snug up the wing nuts. Could get fancy and make up a very accurate oval bushing to fill in the adjustment slot on the scale.

Same arrangement for the reader, although this isn't as critical as making sure the slide and scale are in true alignment.

A couple of pins and snug holes in a mounting plate would also work.

Same arrangement for the reader, although this isn't as critical as making sure the slide and scale are in true alignment.

A couple of pins and snug holes in a mounting plate would also work.

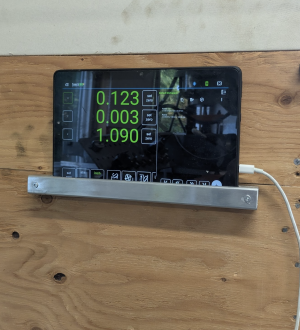

Probably not the best mounting position for the display. Just say'n...We have x axis dro

View attachment 64296

I was hoping to stand it on edge in the slot but the viewing angle is terribleProbably not the best mounting position for the display. Just say'n...

140mower

Don

You need a pair of mirrors, if you only use one to read the scales it will be backwards and you'll put the material back on. 🙄I was hoping to stand it on edge in the slot but the viewing angle is terrible

I'm thinking of doing something very similar for the lathe"mounting".

Here's my current not-really-a-solution:

View attachment 64308

Really I should put it on a pivot arm, but it's been surprisingly handy there to the right of the mill.

140mower

Don

Little shelf looks plenty sturdy,...... reasonably level...... Been there for over two weeks?..... It's permanent. 😉 😛"mounting".

Here's my current not-really-a-solution:

View attachment 64308

Really I should put it on a pivot arm, but it's been surprisingly handy there to the right of the mill.

Nice minimalistic, yet fully functional installation , pretty sure that is what you were aiming for there. 😎

I have been getting a *lot* of use out of 1" aluminium square and angle on these kinds of throw-aways.Little shelf looks plenty sturdy,...... reasonably level...... Been there for over two weeks?..... It's permanent. 😉 😛

Nice minimalistic, yet fully functional installation , pretty sure that is what you were aiming for there. 😎

140mower

Don

I have a supply of old street signs and access to more when needed. It's amazing how handy free 1/8" aluminum sheet can be, especially the ones that are changed out due to reflect ability rather than bullet holes etc.I have been getting a *lot* of use out of 1" aluminium square and angle on these kinds of throw-aways.

Replaced the shop door.

Used to be an interior door with no threshold.

Found a used insulated metal door in good shape and the correct size. Bought door jamb material and weatherstripping and knocked together a new frame.

Quite happy with the reduced sound transmission and increased security.

When it stops raining it will get paint.

Used to be an interior door with no threshold.

Found a used insulated metal door in good shape and the correct size. Bought door jamb material and weatherstripping and knocked together a new frame.

Quite happy with the reduced sound transmission and increased security.

When it stops raining it will get paint.

Last edited:

Crap! You've just made it that much more difficult to do some subtle sabotage. Sorry group. We're going to have to come up with new ideas.Replaced the shop door.

Used to be an interior door with no threshold.

Found a used insulated metal door in good shape and the correct size. Bought door jamb material and weatherstripping and knocked together a new frame.

Quite happy with the reducted sound transmission and increased security.

When it stops raining it will get paint.

View attachment 64621View attachment 64622View attachment 64623

And speaking of new ideas and totally off topic but perhaps a way of distracting @David my little pea seeds have sprouted and are doing nicely. Want to plant them now but I've read that putting rabbit, squirrel and deer food out is not the best idea. So I need to create a protective barrier from the critters. Having said that I don't want to spend hundreds of $'s to save a $20 crop of peas.

Oh and the beans are taking longer but good success there too.

Any suggestions @David?

I've got a bunch of chicken wire fencing that's yours for the taking if you likeCrap! You've just made it that much more difficult to do some subtle sabotage. Sorry group. We're going to have to come up with new ideas.

And speaking of new ideas and totally off topic but perhaps a way of distracting @David my little pea seeds have sprouted and are doing nicely. Want to plant them now but I've read that putting rabbit, squirrel and deer food out is not the best idea. So I need to create a protective barrier from the critters. Having said that I don't want to spend hundreds of $'s to save a $20 crop of peas.

Oh and the beans are taking longer but good success there too.

Any suggestions @David?

View attachment 64625

Tom O

Ultra Member

@jcdammeyer

You have to go to his house at 3:00 am and blast the house with the Mission Impossible soundtrack.

You have to go to his house at 3:00 am and blast the house with the Mission Impossible soundtrack.

It's okay John, you don't need to use code names anymore, marijuana is legal now. lolmy little pea seeds have sprouted

historicalarms

Ultra Member

The wife quit growing peas in her garden...couldnt keep the deer out of them...at least she called them pea's...I call them "deer bait".

When they get a taste for peas you cant keep them out without high fencing.

When they get a taste for peas you cant keep them out without high fencing.

The wife quit growing peas in her garden...couldnt keep the deer out of them...at least she called them pea's...I call them "deer bait".

When they get a taste for peas you cant keep them out without high fencing.

I have the same problem with flowers around the house. In fact, the 4 legged garden mowers routinely wade out into my pond and eat the water lilies I planted there. In summer, I put an e-fence around it to keep them out.