-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

Well this is exciting.

Scales for the lathe.

Knowing you, they will probably be installed before you hit the sack tonight......

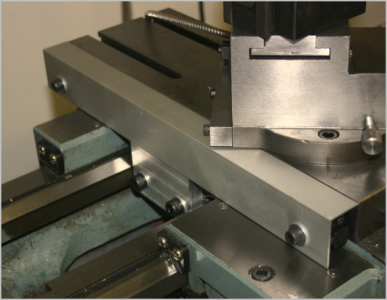

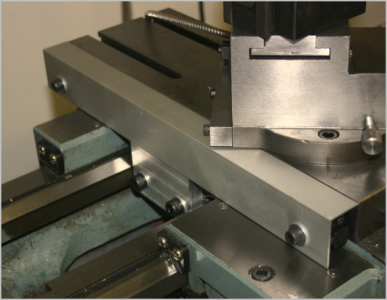

Well I could not have planned that if I tried. The scales just barely fit under the compound base.

Looks like you need to remove a micron or two....

Read my mind!Knowing you, they will probably be installed before you hit the sack tonight......

Grinder? I have a grinder to build?Don't despair Susq, I got my 2x48 grinder built before David did so he can be beaten. lol

No way I can get that done and mount the scale tonight. Something's gotta give! 😀

Well crap. I have to make a decision.

My plan was to put the scale on the tail stock side of the cross slide but the adjustable gib is on that side as are the oil ports and the gib lock.

On the chuck side, there's none of that but it will cover the holes for the follow rest mount.

Now I have never used my follow rest but I have used my gib lock and blocking off the oil ports seems like a recipe for not oiling.

My plan was to put the scale on the tail stock side of the cross slide but the adjustable gib is on that side as are the oil ports and the gib lock.

On the chuck side, there's none of that but it will cover the holes for the follow rest mount.

Now I have never used my follow rest but I have used my gib lock and blocking off the oil ports seems like a recipe for not oiling.

Well crap. I have to make a decision.

It's called "inside". Put it inside your cross-slide. If I'm not mistaken, I see a taper attachment so you don't even need to worry about where to put the reader.

There's no taper attachment on my latheIt's called "inside". Put it inside your cross-slide. If I'm not mistaken, I see a taper attachment so you don't even need to worry about where to put the reader.

But I don't really want to put it under the cross. And I already shelled out for this scale.

Yeah

Yeah that's what I'm thinkingMy vote would be the chuck side. Reason being you'll probably seldom use the follow rest, but you'll want to oil the machine all the time.

My lathe is similar in that regard. I used the existing holes on chuck side of cross slide & mounted my DRO plate there. It has a decent fitting guard over the scale. You can see the guard is close to oilers but still accessible. The right side of the cross table has the lock knob which I use all the time. It acts on the gib strip, also on that side. I thought about trying to integrate the following steady somehow bypassing the plate but its pretty tight in there & you don't want a load device hanging on a measuring device. I told myself when the time comes I need a travelling steady I will make something & utilize the T-slots on the cross slide, which I notice you have too (many do not). The need has not yet arisen for the work I do but I'm sure it will come up sooner or later. I have seen 'light duty stabilizers' mounted this way but I might be overly optimistic about replicating a real steady. hey - i have a 3DP now. Mockup Time!

I opted for the slim 21mm thick scales so I think I can actually still make the follow rest work by making a spacer.If I were to mount a scale on my 12X37, I'd be hard pressed to choose a side. I use the follow rest, and would still want the gibb adjustment. A girl just cannot make up her mind! (evil grin here) 😛

Last edited:

The holes for my follow rest are below the read head so I think I can make a spacer to space the follow rest out away from the slide. It would only need to clear the 21 mm scale. Patting myself on the back for ordering slim scales.My lathe is similar in that regard. I used the existing holes on chuck side of cross slide & mounted my DRO plate there. It has a decent fitting guard over the scale. You can see the guard is close to oilers but still accessible. The right side of the cross table has the lock knob which I use all the time. It acts on the gib strip, also on that side. I thought about trying to integrate the following steady somehow bypassing the plate but its pretty tight in there & you don't want a load device hanging on a measuring device. I told myself when the time comes I need a travelling steady I will make something & utilize the T-slots on the cross slide, which I notice you have too (many do not). The need has not yet arisen for the work I do but I'm sure it will come up sooner or later. I have seen 'light duty stabilizers' mounted this way but I might be overly optimistic about replicating a real steady. hey - i have a 3DP now. Mockup Time!

View attachment 64261

I'll 3D print something first to get the design right then fire up the CNC!

Last edited:

I'm *really* happy with my mag scale under the slide. Clean, out of the way, easy to forget about.There's no taper attachment on my lathe

But I don't really want to put it under the cross. And I already shelled out for this scale.

I hear you...I'm *really* happy with my mag scale under the slide. Clean, out of the way, easy to forget about.

FatherWes

Wes

Does anyone use a snap-in, pinned or other type of quick release attachment method for the scales?

As I understand it, getting it into the exact same place when it’s installed or replaced Isn’t critical, but it needs to be locked in and not move once it is in place.

A quick release latch might allow for easy gib maintenance, oiling, or even follow rest usage etc.

As I understand it, getting it into the exact same place when it’s installed or replaced Isn’t critical, but it needs to be locked in and not move once it is in place.

A quick release latch might allow for easy gib maintenance, oiling, or even follow rest usage etc.

Does anyone use a snap-in, pinned or other type of quick release attachment method for the scales?

As I understand it, getting it into the exact same place when it’s installed or replaced Isn’t critical, but it needs to be locked in and not move once it is in place.

A quick release latch might allow for easy gib maintenance, oiling, or even follow rest usage etc.

That's A GREAT IDEA! But I've never seen one done that way.

You are right, it does not need to repeat.