-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Darren's projects

- Thread starter Darren

- Start date

I couldn't help the laugh icon.... My friend Fred got ultra-precision ballscrews on his 10X50 mill, and he doe curse them from time to time. He had slowed down using it these days, so it is more frequent that he forgets to lock Y.... He and I laugh when it happens!

Nice that you managed the save! That is one powerful machine!

Its only happened twice to me when it has mattered and both times I was able to save the part. On things like facemilling, I don't lock it and it never moves enough to matter.

The first few roughing slots on these parts were done at 0.950" depth and the Y didn't move at all. Got a bit hot so i stepped back to one 0.500 and a 0.450 before I switched to a finishing mill.

Dan Dubeau

Ultra Member

I have always heard that repeated, but this I think is the first instance I have seen of proof that this actually happened to anybody. Glad you were able to save the part.

@Darren you obviously have used both ball screws & regular screws on mills. The other thing I've heard about ball screws is the act of locking can displace the table because they are free-er to move (DRO reads 0.000, lock the axis now DRO reads 0.002"). This seems counterintuitive. Now I think this was coming from a guy who CNC retrofitted an RF-45 or similar mill & those stock dovetail locks are not the best from my own experience, they torque on the gib strip which can add a displacement component.

Peter, my locks don't usually move the table much at all. Maybe a few tenths if anything. I think its probably due to the preload in the ballscrew nuts and bearings. Once in a while the dro will creep off zero on the locked axis while milling after the axis is locked, but its really nothing. I'm not pretending to be Robin Renzetti here.

Had a bit of a situation to deal with tonight. Working on a Promaster van, which uses lug bolts, instead of studs/nuts. It has McGard locking bolts which require a key. The key was broken. I had to weld nuts onto the lock bolts to get them out. My largest extractor for locking nuts was too small. Then i was faced with being two bolts short to send the van out. Can't get new ones till Tuesday. So i figured i'd machine a hex on the original locks to get them back in service for a few days. Problem was, my 5/8" (16mm) 5c collet wouldn't tighten down enough on the 15.5mm shank to use my hex collet block. Was in a rush, precision wasn't a concern, so i came up with this. Thought you fellas might find some value in it.

![20240419_180015[1].jpg 20240419_180015[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54640-20e3d48799807a45c81e268a3fa67eba.jpg?hash=0AtCXHFv_u)

![20240419_181635[1].jpg 20240419_181635[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54641-20f099fd0e18ae741ef14d9b463053b1.jpg?hash=UyRbC24dGX)

![20240419_183632[1].jpg 20240419_183632[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54642-0ed44a8f47965c8e47170c01eed7fdfe.jpg?hash=lsx7UlbsAC)

![20240419_185548[1].jpg 20240419_185548[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54643-9bd64aabd8ed2226a0277e3d2b7a2000.jpg?hash=gn2eQCVEQG)

Worked good enough to get em back on for a few days. Socket fits good. Felt like a pretty fart smeller after.

![20240419_180015[1].jpg 20240419_180015[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54640-20e3d48799807a45c81e268a3fa67eba.jpg?hash=0AtCXHFv_u)

![20240419_181635[1].jpg 20240419_181635[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54641-20f099fd0e18ae741ef14d9b463053b1.jpg?hash=UyRbC24dGX)

![20240419_183632[1].jpg 20240419_183632[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54642-0ed44a8f47965c8e47170c01eed7fdfe.jpg?hash=lsx7UlbsAC)

![20240419_185548[1].jpg 20240419_185548[1].jpg](https://canadianhobbymetalworkers.com/data/attachments/54/54643-9bd64aabd8ed2226a0277e3d2b7a2000.jpg?hash=gn2eQCVEQG)

Worked good enough to get em back on for a few days. Socket fits good. Felt like a pretty fart smeller after.

Last edited:

Locking lug nuts are the most useless things ever. I have a cordless impact and extractors and they normally wouldn't even slow me down. Anyone who has worked on German cars with lug bolts knows how tight normal lug bolts get over time. A bolt torqued to 80 ft/lbs feels like 200 after its been on there a while. So the keys for the locking versions break all the time. These guys are lucky they never got a flat. Last guy put the broken key back in the glove box. The one where i welded the nut with a few tacks is the one they broke it on. It was not that tight and still had remnants of the key in it.

Last edited:

I just got a set of 5c collets, mine are not Accusize though, Findmall brand. Acceptable for the kind of halfassed precision work i was doing, but not great.Anyone have this set of Accusize 5c collets? I'd like to try them but import collets make me nervous.

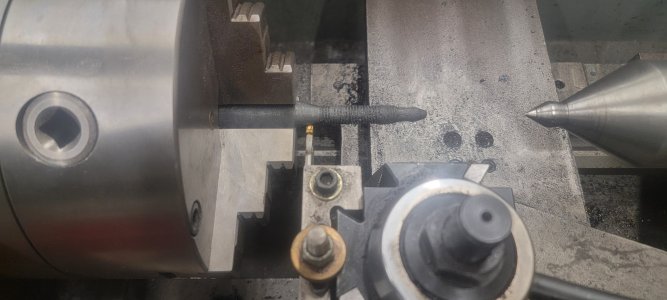

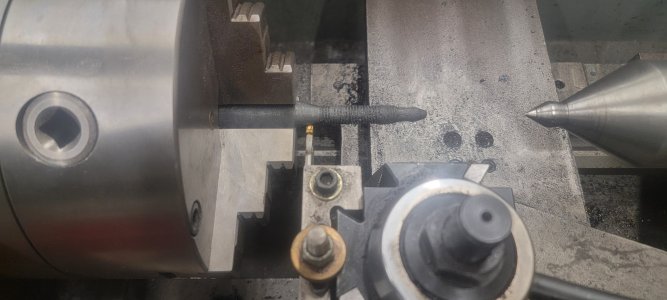

I'm working on a 2002 Ford F550 in the shop. I had to lift the cab off the frame for some engine work. Had trouble with the cab mounts. The nut plates are so rotten that the threads fell apart when I went to bolt them back up. The fix is longer bolts to go all the way through and put nuts on the bottom. One cab bolt is a special bolt that has a fat shank for body alignment. Here's what I did to make it 1.5" longer.

The mount looking up from the floor. Those are supposed to be threads inside.

The special bolt:

Parted off the 12mm threaded section:

Tapped for 1/2" 13:

Screwed in a chunk of allthread:

Now it can pass all the way through the mount and get a nylock nut and flat washer.

The mount looking up from the floor. Those are supposed to be threads inside.

The special bolt:

Parted off the 12mm threaded section:

Tapped for 1/2" 13:

Screwed in a chunk of allthread:

Now it can pass all the way through the mount and get a nylock nut and flat washer.

140mower

Don

Nice repair.... And another great reminder why I love my old trucks....... Taking the cab off to perform some engine work, I remember when those were found under the hood, in the engine compartment..... 🙄 😡I'm working on a 2002 Ford F550 in the shop. I had to lift the cab off the frame for some engine work. Had trouble with the cab mounts. The nut plates are so rotten that the threads fell apart when I went to bolt them back up. The fix is longer bolts to go all the way through and put nuts on the bottom. One cab bolt is a special bolt that has a fat shank for body alignment. Here's what I did to make it 1.5" longer.

The mount looking up from the floor. Those are supposed to be threads inside.

View attachment 54846

View attachment 54847

The special bolt:

View attachment 54848

Parted off the 12mm threaded section:

View attachment 54849

Tapped for 1/2" 13:

View attachment 54850

Screwed in a chunk of allthread:

View attachment 54851

Now it can pass all the way through the mount and get a nylock nut and flat washer.

Yeah, how sick & twisted was that?I remember when those were found under the hood, in the engine compartment...

Had to change the oil pan, the engine had to be lifted pretty high to get it out. The pan was as rotten as the cab mounts....but its a plow truck and spends its life in the salt.

Interesting story about this truck. It started out as a 2wd 20' box truck. I cut 5 feet out of the middle, converted it to 4wd and built the dump deck. Its been the best truck in my buddies fleet. He's made a million bucks with it. So annual major repairs aren't really a big deal.

Interesting story about this truck. It started out as a 2wd 20' box truck. I cut 5 feet out of the middle, converted it to 4wd and built the dump deck. Its been the best truck in my buddies fleet. He's made a million bucks with it. So annual major repairs aren't really a big deal.

Been pretty busy lately with customer vehicles, but got tired of tripping over unfinished projects, namely the airline project.

Built a platform for the compressor. The blast cabinet is going to live underneath it. Lifted the compressor up with my bobcat with forks, solo at 1am on Friday night. Got it sort of in place on the platform and realized that I couldn't open the door, so no pics of the lift.

Then began the hard piping, drains, before starting up the wall with 3/4" pex , with 3d printed clips.

I'll have 4 drops on the lifts, one on each post with a drain leg. Then it's going to head across to the machine shop area.

Oddly enough, I thought the compressor was going to be louder being 10' higher, but it's actually significantly quieter

Built a platform for the compressor. The blast cabinet is going to live underneath it. Lifted the compressor up with my bobcat with forks, solo at 1am on Friday night. Got it sort of in place on the platform and realized that I couldn't open the door, so no pics of the lift.

Then began the hard piping, drains, before starting up the wall with 3/4" pex , with 3d printed clips.

I'll have 4 drops on the lifts, one on each post with a drain leg. Then it's going to head across to the machine shop area.

Oddly enough, I thought the compressor was going to be louder being 10' higher, but it's actually significantly quieter

Another interesting project tonight. Working on a Hyun dai 1.8L engine. It came to me as a no start. Found that the exhaust camshaft was not turning. The timing chain was intact, so I pulled the cover and the timing gear/cam phaser. The pin that aligns and drives the cam had walked deeper into its bore in the cam.

I have seen this before, while working at the dealership. We would replace the cam and gear and send it out. I am unaware if they fixed the issue of the bore being deeper than the length of the pin, so I decided to see about fixing this one on my own.

The pin is 4.815 mm in diameter. I extracted it and replaced it with a broken tap shank that was slightly larger at 4.91 mm that I'd been saving for such an occasion.

Here's some pics:

You can see that the pin walked in till it was flush.

Some minor damage to the mating bore in the phaser.

I pulled the cam and wrapped it up for some welding. Welded a 5mm washer to the pin, then a 10-24 machine screw with a nut to pry against. It came out very easy.

Cleaned up the broken tap by slicing it off , and tapped it in with some loctite, until it was bottomed out.

I'll trim it off to the proper length tomorrow and reassemble everything. I may bore and install a bushing in the gear,, but i don't think I will have to.

I have seen this before, while working at the dealership. We would replace the cam and gear and send it out. I am unaware if they fixed the issue of the bore being deeper than the length of the pin, so I decided to see about fixing this one on my own.

The pin is 4.815 mm in diameter. I extracted it and replaced it with a broken tap shank that was slightly larger at 4.91 mm that I'd been saving for such an occasion.

Here's some pics:

You can see that the pin walked in till it was flush.

Some minor damage to the mating bore in the phaser.

I pulled the cam and wrapped it up for some welding. Welded a 5mm washer to the pin, then a 10-24 machine screw with a nut to pry against. It came out very easy.

Cleaned up the broken tap by slicing it off , and tapped it in with some loctite, until it was bottomed out.

I'll trim it off to the proper length tomorrow and reassemble everything. I may bore and install a bushing in the gear,, but i don't think I will have to.

Last edited:

Nicely done! You deserve a pat on the back for that innovative solution.Another interesting project tonight. Working on a 2018 Hyundai Elantra 1.8L engine. It came to me as a no start. Found that the exhaust camshaft was not turning. The timing chain was intact, so I pulled the cover and the timing gear/cam phaser. The pin that aligns and drives the cam had walked deeper into its bore in the cam.

I have seen this before, while working at the dealership. We would replace the cam and gear and send it out. I am unaware if they fixed the issue of the bore being deeper than the length of the pin, so I decided to see about fixing this one on my own.

The pin is 4.815 mm in diameter. I extracted it and replaced it with a broken tap shank that was slightly larger at 4.91 mm that I'd been saving for such an occasion.

Here's some pics:

View attachment 61380

You can see that the pin walked in till it was flush.

View attachment 61381

Some minor damage to the mating bore in the phaser.

View attachment 61382

I pulled the cam and wrapped it up for some welding. Welded a 5mm washer to the pin, then a 10-24 machine screw with a nut to pry against. It came out very easy.

View attachment 61383

Cleaned up the broken tap by slicing it off , and tapped it in with some loctite, until it was bottomed out.

View attachment 61384

I'll trim it off to the proper length tomorrow and reassemble everything. I may bore and install a bushing in the gear,, but i don't think I will have to.