-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Ontario GTA West area meetup is planned for Saturday April 26th at Greasemonkeys shop in Aylmer Ontario. If you are interested and haven’t signed up yet, click here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Darren's projects

- Thread starter Darren

- Start date

I'm in the same position with regard to D1-6 pins. I have a backing plate without pins, but I might have a go at making some from 4140.

I'll have a look at home. Might have some D1-6 pins.

An alternative would be to buy a cheap dog drive plate on ebay. I saw dozens go cheap when I was looking for a faceplate for my 16x60

@dfloen Thanks that would save me some hassle I found some from Mac at 13.99 US$ each, plus shipping (if they will)

@Brent H Thanks anyway I have some I can measure.

For those looking for cam pins, try here:

www.macit.com

www.macit.com

@Brent H Thanks anyway I have some I can measure.

For those looking for cam pins, try here:

Cam Stud | Mac-It Corporation

All i could picture was the tongue snapping off and the lathe getting launched into the ditch.

Sometimes I think I overthink that possibility. It's hard to look at a tongue and/or a hitch and not worry about it breaking under on-road forces. Thankfully it has never happened to me and I'm glad you made it too!

.

HP and Torque seem to get confused. Constant torque does you little good - you want torque to go up as speed goes down to maintain constant HP.

I'd be remiss if I didn't comment here. A few of the forum members and I have agreed to disagree on this point.

HP is the rate at which work is done. Torque is a measure of rotational force required to do work. As long as you don't try to take a deeper cut as you slow down, you do not need more horsepower. Slower speeds mean less chip removal per unit time therefore less hp is required. But you do need to have the torque required to make the cut or the lathe will stall and bad things will happen.

I think your project is awesome. And I do agree with others that you should try to keep the original power train intact if you can.

I had glass scales on my other Emco V10P lathe. They were fine, but a bit bulky on a smaller machine. Also, magnetic scales can be easily trimmed, which i did on two of these. Lastly, these are said to be unaffected by chips/coolant. I ordered from Amazon. I did find it slightly cheaper elswhere, but i trust Amazon a bit more. With a bit more patience I could have ordered direct from Ditron with the scales cut to my needs. I did it myself, it was easy to trim them.

I am pretty much decided to go with magnetic scales too. I don't have any DROs on anything yet. My mill will be my first one. I'll be watching how this goes for you and may have questions in time.

I loved your rear pickup for rpm. What a great idea! I am planning to switch my lathe motor from single phase to three phase so I can install a VFD and get slower speeds. Having an rpm readout on the dro will be handy when that time comes.

I just want to add that I love how you are involving all of us on your journey through this project. I learn so much from such stories and I REALLY APPRECIATE you telling yours!

@dfloen Thanks that would save me some hassle I found some from Mac at 13.99 US$ each, plus shipping (if they will)

@Brent H Thanks anyway I have some I can measure.

For those looking for cam pins, try here:

Cam Stud | Mac-It Corporation

www.macit.com

Now you tell me that!!!

Like @Brent H , I tried many times to find cam studs so I could skip the need for a backplate on some of my custom chucks.

I think I may have purchased my last backplate! Thank you @Dabbler !

Does your Maximat cross slide have any kind of table lock? My 14x40 has the rudimentary screw acting against the gib strip on the RHS. It's not the best system in the world & I made some subsequent improvements to the locking mechanism. But I was unwilling to do without it, so I ended up putting the DRO on the LHS which wasn't my favorite option. Its reasonably well protected with the guard. So far so good..

My compound also had a DRO axis but after many years I think it was cable movement that caused an issue. One day I noticed some glitching digits, next day was out for good. It might also be the encoder hardware itself but my hunch is repeated flex right where the armored cable enters the unit. I decided for the $ replacement I didn't use it as much as I thought so the compound is bare dials again.

It does have a cross slide lock, behind the scale. I have a plan to make it work. I was going to mount the scale on the headstock side but the holes were already drilled and tapped on the tailstock side. But if i space it off a bit i can get a wrench in there. I'll worry about that when i do the guards.

I will pay close attention to the cable management so that the cables cant flex at the reader.

I am pretty much decided to go with magnetic scales too. I don't have any DROs on anything yet. My mill will be my first one. I'll be watching how this goes for you and may have questions in time.

I loved your rear pickup for rpm. What a great idea! I am planning to switch my lathe motor from single phase to three phase so I can install a VFD and get slower speeds. Having an rpm readout on the dro will be handy when that time comes.

I just want to add that I love how you are involving all of us on your journey through this project. I learn so much from such stories and I REALLY APPRECIATE you telling yours!

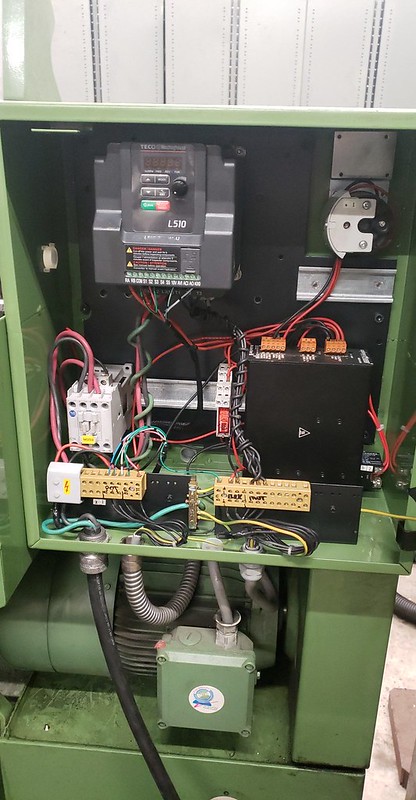

I also swapped in a VFD to control this lathe. Its well worth the effort. This lathe already had a 3 phase, 3hp motor. The Teco VFD was only a few hundred

With variable speed within each of the gears, its handy to know what RPM the spindle is actually turning.

Thank you for your comments!

HP is the rate at which work is done. Torque is a measure of rotational force required to do work. As long as you don't try to take a deeper cut as you slow down, you do not need more horsepower.

I did not say you need more HP. I said when you slow down, you need more torque to have the same HP. There is no mystery to to this. HP is the product of torque and rpm. Do you disagree with that formula?

Slower speeds mean less chip removal per unit time therefore less hp is required.

That would be true if diameter was the same. In discussing a lathe's available power over its speed range, I would have thought that implied different diameters. Usually you would usually keep the cutting speed, FPM, roughly the same and vary speed with diameter. As diameter goes up (i.e. speed goes down to maintain the cutting speed), torque must go up to have the same removal rate in cubic inches per minute (i.e. HP or work).

Maybe an example would clarify things in case I'm not presenting this clearly - the following assumes with a 50 thou DOC and .005 feed rate

Scenario 1)

1" dia, speed 400 rpm. = 104 feet per minute. Removal rate (or work) = about .3 cubic inches per minute

Scenario 2)

6" dia, speed 66 rpm. = 104 feet per minute. Removal rate (or work) = about .3 cubic inches per minute

Scenario 1 & 2 both require the same power (HP) and do the same work (approx .3 cubic inches per minute). Scenario 2 requires 6x the torque as Scenario 1 (as both scenarios MUST have the same power and speed has gone down so torque must go up)

What is there to disagree about? The formulas are well established. I don't want to take the OP's topic further astray, but suffice to say the 10ee drive gives much better performance than a constant torque VFD

Last edited:

I spent a bit of time tonight measuring for wear on the lathe bed, and I'm pretty happy so far. Its still on the trailer, and needs a good cleaning but my 1/2 thou mitutoyo indicator showed maybe 2 or 3 tenths up close to the headstock on the front v way, and maybe 1/2 thou on the rear flat way and about the same for the tailstock ways. Pretty rudimentry measuring but if there was anything major, I think i would have seen it. No dips or valleys, or craters.

So its not scrap, I can move forward with some plans for it.

So its not scrap, I can move forward with some plans for it.