This arrived today.... Ordered on the 11th. $124.39 shipped. https://d-gray-drafting-and-design.myshopify.com/

It was certainly well packaged.....

It was certainly well packaged.....

Last edited:

Look forward to your build & testing. I cant figure out the knurled tension knob on these styles. I have limited experience but I've used:

- bump style knurlers ( work fine but too hard on parts & machine IMO)

- a very poorly made Asian contraption (not even worth mentioning)

- an Armstrong (USA made scissor style), decent but has some shortcomings IMO

- AccuTrak (better USA made scissor style). Both USA models presumed some kind of wrench to apply enough force on the scissor action & arguably had higher leverage mechanics relative to axle & wheel. Same deal for the Doug Ross knurler I attached YouTube link for in the other post.

@YYCHM hey Craig did you get the metric kit or imperial kit? I assume the latter.

Imperial. Now I have to source a 5/16-24 tap and a 5/16 reamer

Hey Craig you mean to say holes are not drilled or tapped? Why do you require the reamer? Kindly fill in the planks as there may be others interested in obtaining a kit. Just saying!

I'm not picking on this design in particular because I have seen several variants in model engineering circles. But I'd be interested in how this style works with (only) finger torque tensioning. Do the instructions infer running the knurl back & forth with increasing tension or....?

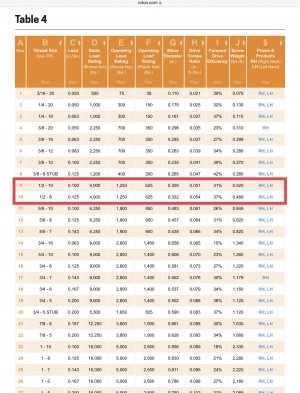

So was I until I found some numbers which set my mind at ease…I wonder about this pressure on the lead screw while people are bragging about 100 - 150 + depth of cut using said screw and not concerned about pressure.

@RobinHood - thanks for that info.I would assume that during most cutting / knurling operations the compound (as well as the cross slide) would be stationary. So, static load is 4000 lbs and operating load is 1250 lbs for a 1/2-10 Acme.

I generally bring my scissor-style knurler up to the work so that the two wheels are just shy of being on the diamater axis of the workpiece, finger tighten, and then use the cross-slide to roll the now tight wheels onto the center of the piece. Dunno if that's how you're supposed to do it, but it's worked for me.

Good discussion. My own personal conclusion is I now want to try a cut knurler.