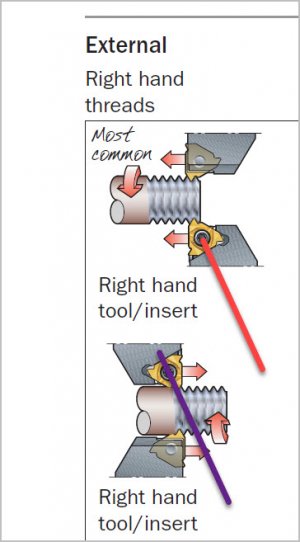

Maybe depends on the setup & tooling but wouldn't the compound angle be the same in either way feed direction? In the case of your part where the thread is well back of the shoulder, there would be lots of room to turn a thread relief groove, desirable in both cases. If the thread ends at the base of a much larger diameter shoulder, then yes, some tooling ight not work as well. But in HS to TS mode, you would position tool vee in groove, advance the depth of cut, then engage the half nuts. Also something like a internal right hand threading tool could work here as well as long as the part was not supported by a tail stock center which would interfere with toolpost/holder on operator side of part.

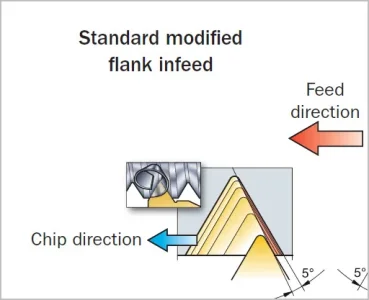

Also fine / shallow DOC threads in mild materials often can get away with not being at magic 29.5 deg. I've gone straight in with inserts & there there is no appreciable difference in finish or fit. Sometimes the insert manufactures tables even show this to be the case (but may have other methods of compensation). As threads get bigger & materials get tougher & lead screw backlash is a concern, the compound set becomes important & works to your advantage.

Also fine / shallow DOC threads in mild materials often can get away with not being at magic 29.5 deg. I've gone straight in with inserts & there there is no appreciable difference in finish or fit. Sometimes the insert manufactures tables even show this to be the case (but may have other methods of compensation). As threads get bigger & materials get tougher & lead screw backlash is a concern, the compound set becomes important & works to your advantage.