Ahhhh, I see! The job just got easier.

If you think trucks drive over poles, you should see what farm tractors do in the mixed forest/rock/farmland around here! I'm forever fixing lights, brackets, and frames on tractors and farm equipment!

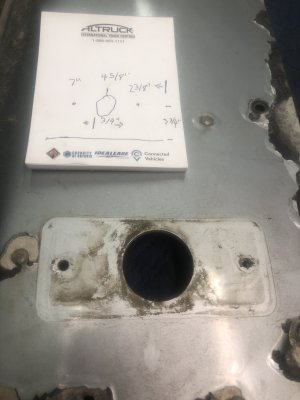

Here is what I would do. KISS. I'd staple a piece of paper to a piece of plywood or junk wood. I'd put the plywood and paper behind the old sheet metal, spray paint a template or use punches and/or hole saws to mark the paper. Remove the paper and glue it to (or hold it against) the new sheet metal. Drill and cut new holes.

If you want to be a bit more precise, I'd assume you have a caliper (but maybe not a DTI - Dial Test Indicator

@LenVW ).

Use the inside edge jaws of the caliper to measure the distance center to center of the screw holes. Call this D. The location of the bulb hole is D/2.

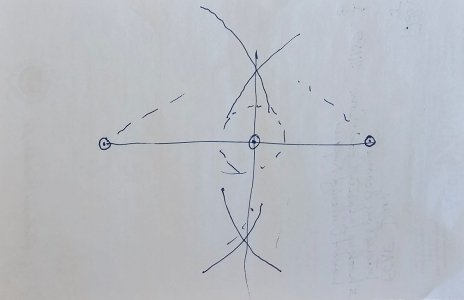

You can also use a geometry divider to locate the center hole. Locate the two screw holes with a marker, and draw a line between them. Use a divider (can be home made with holes for a screw and for a marker) to make arcs from both holes above and below the center hole. Draw a vertical line between the intersections. That locates the light hole.

If you don't have a geometry set, make a wooden divider with a nail for the screw centers and a hole drilled for a marker pen to draw the arcs.

View attachment 63498

See, my cad skills are just like yours!

Even easier is to lock your caliper at someplace slightly more or less than the center distance - no need to be precise. Mark the center from both screw holes - the true center is exactly 1/2 way between the two marks. Easy to eyeball.