Chris Cramer

Super User

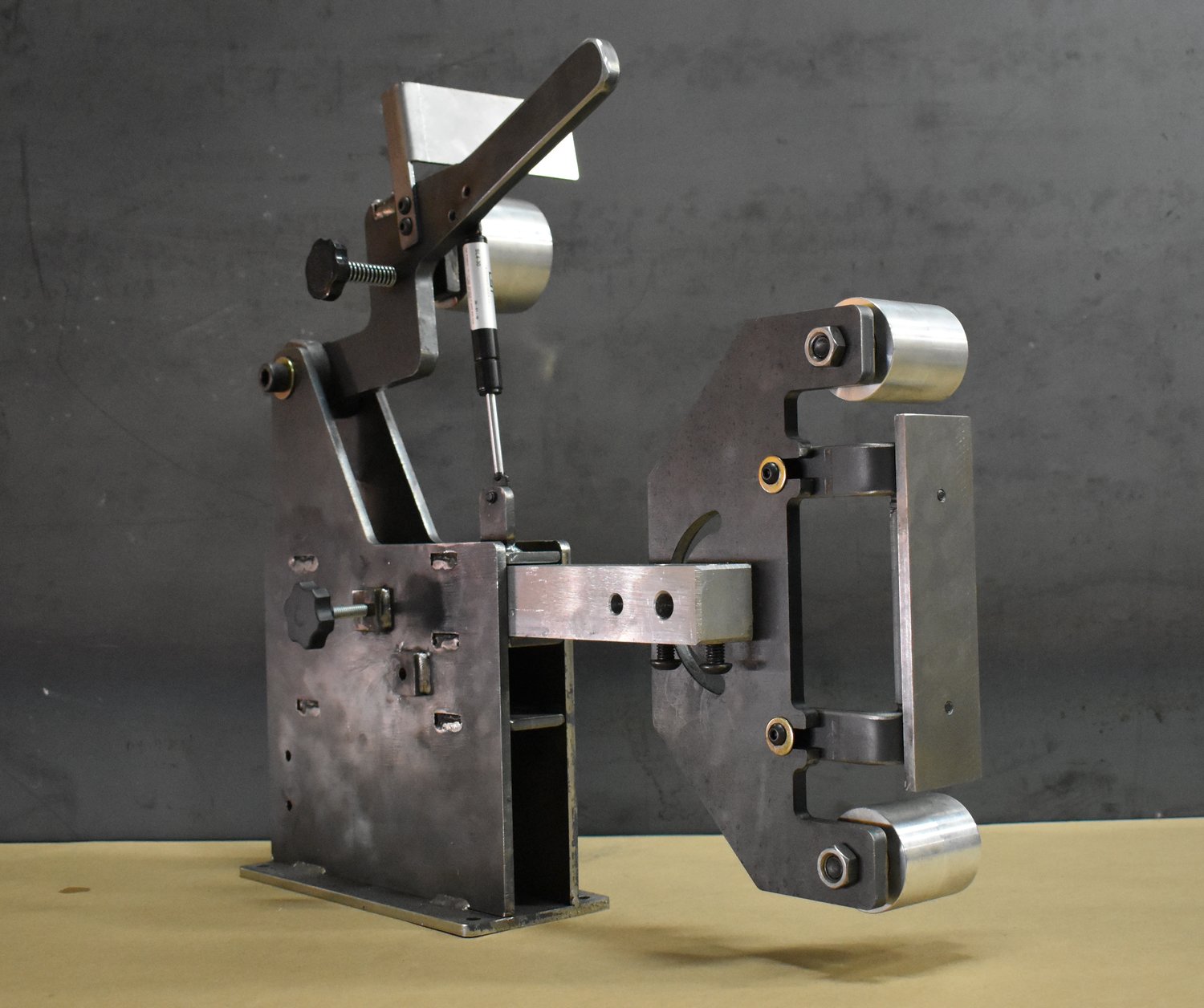

My 2hp 3 phase motor worked very well for a while, with my home built 2x72 belt grinder after I installed a VFD to give me control over the speed and direction of the belt. The only thing now is after I installed a 10" rubber contact wheel and re aligned the wheels I have had trouble keeping the belt perfectly straight.

By how much time and money I put into blade smithing now, I have thought about purchasing a professional 2x72 belt grinder. Does anybody know of a very reliable model within Canada that is within my budget of $2000? I have seen several grinders online that are affordable and also have VFD, however, by the reviews I have read and the fact that they are Chinese makes me doubt that they would be reliable.

Almost every commercial grinder from the US is above $3000, and I definitely am not at that point yet. I am only looking for a grinder that would last and will be a big improvement from my home built grinder which has worked pretty well.

By how well it worked before my electronic upgrade of the VFD, and additional contact wheel I have also thought about redesigning the chasis with the contact wheel to help realign the wheels.

By how much time and money I put into blade smithing now, I have thought about purchasing a professional 2x72 belt grinder. Does anybody know of a very reliable model within Canada that is within my budget of $2000? I have seen several grinders online that are affordable and also have VFD, however, by the reviews I have read and the fact that they are Chinese makes me doubt that they would be reliable.

Almost every commercial grinder from the US is above $3000, and I definitely am not at that point yet. I am only looking for a grinder that would last and will be a big improvement from my home built grinder which has worked pretty well.

By how well it worked before my electronic upgrade of the VFD, and additional contact wheel I have also thought about redesigning the chasis with the contact wheel to help realign the wheels.