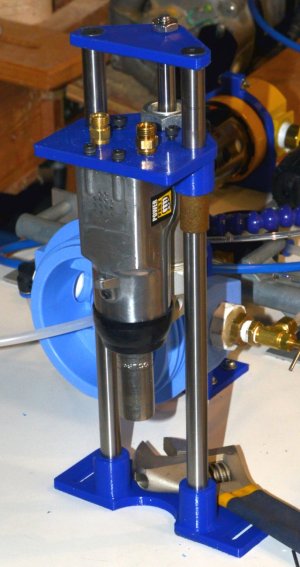

I'm in the process of building up this type of power draw bar. The air cylinder is pushed down by both the CW and CCW air to the impact wrench. Once the air is removed the project plans call for springs to return the assembly back up. ID of the springs would have to be 0.6" or so to clear 1/2" shafts. The project plans called for an air cylinder that had an internal spring but Princess Auto didn't have anything like that.

The model in the photo is exactly that. Just 3D printed parts to see how things 'feel'. Until I finish the mounting base on the mill I won't know how long to make the 1/2" polished shafts so I cut them longer for now. They are threaded 1/4-20 x 3/4" in the top and are a nice press fit in the 3D printed base. I haven't pushed the bronze bushings all the way in. The pieces will all be cast aluminium but I can't do that until we get some rain so the ground isn't so eager to catch fire with stray sparks.

The model in the photo is exactly that. Just 3D printed parts to see how things 'feel'. Until I finish the mounting base on the mill I won't know how long to make the 1/2" polished shafts so I cut them longer for now. They are threaded 1/4-20 x 3/4" in the top and are a nice press fit in the 3D printed base. I haven't pushed the bronze bushings all the way in. The pieces will all be cast aluminium but I can't do that until we get some rain so the ground isn't so eager to catch fire with stray sparks.