Thanks for the link Tom. I’ll keep them on the back burner if things don’t pan out.

While i wait for stronger wave spring washers to come in, I’ll push ahead with the bronze bearings in the clutch baskets. They are a right old mess: two spun in the FWD basket (A) and were “welded” to the shaft. The REV basket (B) had one still pressed (and locktited) in and the other was spinning both on the shaft and in the basket bore.

General overview of the parts. Bronze bearings are in front of each basket.

Close-up of the REV basket. You can see the space between the two bearings. It is crucial as that is where the pressurized oil enters through a hole in the bearing journal.

And the much worn FWD basket bearings. The required gap between them is completely gone because of wear on the shoulder of the inner half.

A picture of the clutch drive shaft with the lubrication holes in the journals.

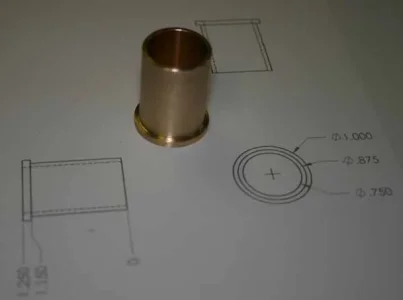

Close-up of one half of the bearing - the shoulder takes up axial thrust. The oil grooves allow lubrication of both the shaft journal and the ball bearing supporting the clutch shaft. (In the pictures above, only the front double row ball bearing is still on the shaft - the rear one had to come off in order to extract the shaft from the HS.

And the very worn inner half - the shoulder is supposed to be 5.0mm!

Here the old bearings are in their respective baskets and the “naked“ clutch pack is between them; this set-up was used to determine the required width of each bearing shoulder. (The output gears are also missing off of each basket journal - the locating key ways are visible).

My plan is to make the new bearings a proper press fit (no locktite). Then finish-bore to shaft size after. A shoulder protrudes on each end. This is critical, as it sets the end play of the clutch pack. The old ones allowed the clutch pack to slide axially by almost a 1/4”! That would have made for a very sloppy clutch feel.

What size bearing bore would you use to allow a proper oil film lubrication and yet not have excess radial play? I am also expecting the bearings to expand a bit as they warm up. The shaft journals are 27.99mm and 32.99mm respectively.

There is a Figure 6 in the MHB (29th ed, pg 2331) giving a range of about 0.0014“to 0.0042“ operating diameteral clearance for the small journal and about 0.0016” to 0.0045” for the larger one. They also go into an extended calculation of lubricant film thickness. I have too many unknowns and thus can’t complete the math. Hence the question about bore size vs given journal diameter above.