Wave Spring Washers

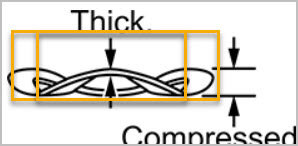

Working on my new to me lathe. I knew the clutch would need some work. Plain bearings in it are shot (knew that). But now I found 4 broken wave spring washers. They keep the plates separated when the clutch is not engaged. One side is always free wheeling when the other is transmitting power. Both could be free wheeling as well - lathe running, but spindle stopped. They can never be engaged at the same time. Some pictures of what I am talking about.

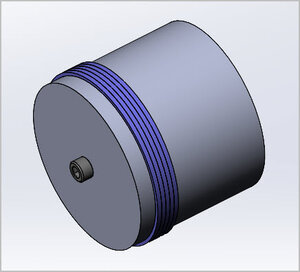

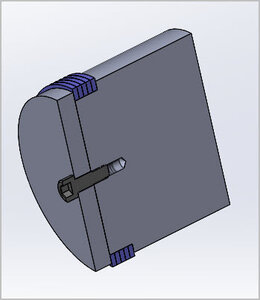

Clutch pack: one side is FWD other is REV (does not matter which way the cartridge inside is installed as it is symmetrical - baskets are specific to direction of operation, however).

You can see the broken wave washers in the bottom left. The two whole looking ones have a crack each.

The washer nests inside each of the 7 driven plates. Like so. There are 9 drive plates (Including the end and compression plate).

One side of the cartridge cleaned and assembled. You can see the plate stack. The wave washer keeps the drivers spaced away from the driven to open the clutch —> normal position.

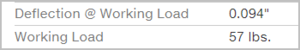

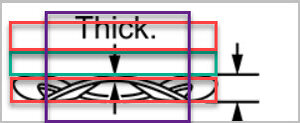

Here are the specs of each washer.

Pretty sure they were custom made in the factory by Baruffaldi in Italy - the clutch manufacturer. Baruffaldi still exist today, but don’t seem to make these clutches any more. They now make precision CNC tool changers for live/dead tooling. https://www.baruffaldi.it

I will try Baruffaldi to see if they still have some NOS.

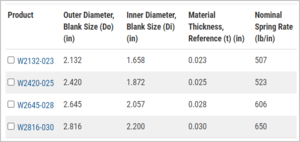

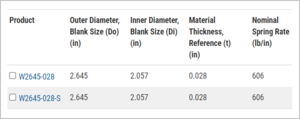

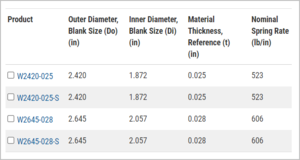

McMasterCarr has something similar; it would need modification of ID/OD.

https://www.mcmaster.com/wave-washers/wave-disc-springs-7/id~2-2/.

The ID would need opening and the OD reducing. I would do that with the TPG on the lathe.

The thickness is either too thin or too thick - not by much, just a few thou. That I would not be able to modify on a formed washer. Only on raw stock as I could surface grind it to size.

Have any of you ever made wave washers from annealed spring steel?

How easy would it be to harden it afterwards?

Would two washers on either end of a stack of 7 cause any problems if they are a little stiffer, if I use the ones from McMaster (0.0234” required vs 0.025” as purchased)?

Open to any ideas/suggestions.

Working on my new to me lathe. I knew the clutch would need some work. Plain bearings in it are shot (knew that). But now I found 4 broken wave spring washers. They keep the plates separated when the clutch is not engaged. One side is always free wheeling when the other is transmitting power. Both could be free wheeling as well - lathe running, but spindle stopped. They can never be engaged at the same time. Some pictures of what I am talking about.

Clutch pack: one side is FWD other is REV (does not matter which way the cartridge inside is installed as it is symmetrical - baskets are specific to direction of operation, however).

You can see the broken wave washers in the bottom left. The two whole looking ones have a crack each.

The washer nests inside each of the 7 driven plates. Like so. There are 9 drive plates (Including the end and compression plate).

One side of the cartridge cleaned and assembled. You can see the plate stack. The wave washer keeps the drivers spaced away from the driven to open the clutch —> normal position.

Here are the specs of each washer.

Pretty sure they were custom made in the factory by Baruffaldi in Italy - the clutch manufacturer. Baruffaldi still exist today, but don’t seem to make these clutches any more. They now make precision CNC tool changers for live/dead tooling. https://www.baruffaldi.it

I will try Baruffaldi to see if they still have some NOS.

McMasterCarr has something similar; it would need modification of ID/OD.

https://www.mcmaster.com/wave-washers/wave-disc-springs-7/id~2-2/.

The ID would need opening and the OD reducing. I would do that with the TPG on the lathe.

The thickness is either too thin or too thick - not by much, just a few thou. That I would not be able to modify on a formed washer. Only on raw stock as I could surface grind it to size.

Have any of you ever made wave washers from annealed spring steel?

How easy would it be to harden it afterwards?

Would two washers on either end of a stack of 7 cause any problems if they are a little stiffer, if I use the ones from McMaster (0.0234” required vs 0.025” as purchased)?

Open to any ideas/suggestions.

Last edited: