Well, if we didn't have enough drill point grinding....here's another one.

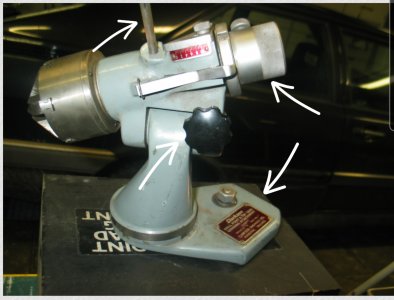

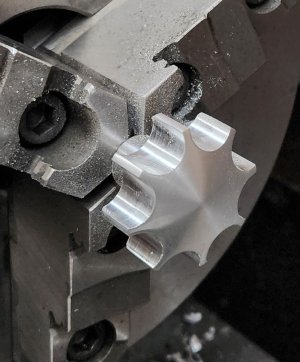

I received this today and cleaned it up. It's missing some parts that I can make. The base maybe a little more difficult since I don't know the exact shape and where the index mark is supposed to be. The first picture is what I have, the others indicate what I need.

Maybe @RobinHood has one. He has everything else!!

I received this today and cleaned it up. It's missing some parts that I can make. The base maybe a little more difficult since I don't know the exact shape and where the index mark is supposed to be. The first picture is what I have, the others indicate what I need.

Maybe @RobinHood has one. He has everything else!!