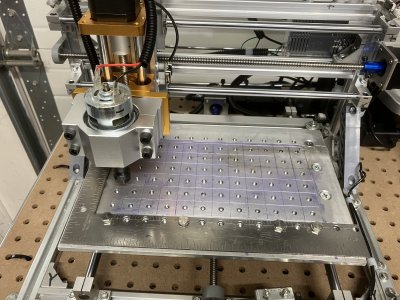

Here’s my latest iteration of cheap engravers. 3018 CNC router with aluminum spoil board (6 mm tapped holes on 20 mm centres), and Jinsoku LE-1620 laser engraver. Table is a roll-around shelf unit I snagged from a grocery store that was buying new fixtures and blowing out their old shelves. Rock solid, and a layer of 1/4” pegboard makes a nice work surface.

The laser engraver has an aluminum spoil board with hold-down holes matching the pegboard holes. Rube Goldberg air assist made from an aquarium pump and some vinyl tubing.

$100 PC with $15 monitor, no big worries if they get fried when something goes wrong. Spent more money on software than hardware. ESTLCAM for the router, Lightburn for the laser.

The laser engraver has an aluminum spoil board with hold-down holes matching the pegboard holes. Rube Goldberg air assist made from an aquarium pump and some vinyl tubing.

$100 PC with $15 monitor, no big worries if they get fried when something goes wrong. Spent more money on software than hardware. ESTLCAM for the router, Lightburn for the laser.