Elektrishun

Ultra Member

Not sure I get the theme of this thread. Isn't this our SOP ? Isn't this why we spend thousands upon thousands of dollars on tools ?😳

Janger is simply creating a platform to network ideas for developing potential cost savings tactics which he can then actualize into concrete strategies in order to broaden his shop equipment purchase acquisition portfolio.

For example, telling your wife that you know women who would kill to have grey hair like hers. Then calculate how much you will save on hair coloring product = a new set of quality cobalt drill bits.

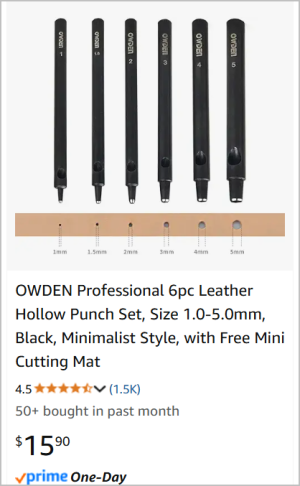

![IMG_0458[1].JPG IMG_0458[1].JPG](https://canadianhobbymetalworkers.com/data/attachments/74/74545-9b6e9a0315a48b3f9b673b0b839031fb.jpg?hash=abPkzmwM7U)

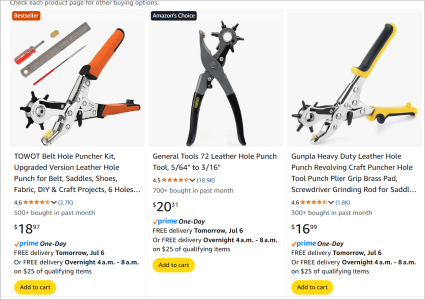

![IMG_0460[1].JPG IMG_0460[1].JPG](https://canadianhobbymetalworkers.com/data/attachments/74/74546-b6f9d910995ff2223627f9dfa4aaa67b.jpg?hash=1pO4UK8vmg)