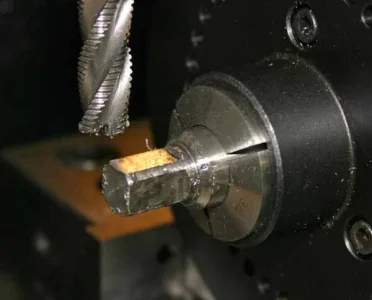

I've always struggled with centering work in a 4J. Some times it would take me over an hour in order to get something even remotely close.

These instructions work, and work great. https://littlemachineshop.com/images/gallery/PDF/centering4-jawchuck.pdf

Now if I could only find something similar for tramming the vise square on my mill.....

These instructions work, and work great. https://littlemachineshop.com/images/gallery/PDF/centering4-jawchuck.pdf

Now if I could only find something similar for tramming the vise square on my mill.....