I'm bad. I ask you guys a question and then disappear. I am sorry about that and my apologies. Harvest time came early this year and caught me off guard.

Took some time this morning while my beans are still full of dew to get the cover off, investigate options, and write this post. There are lots of options. That big bull gear literally screams "PICK ME, PICK ME!"

1. I could drill a hole in the side of the housing to install an automotive engine position sensor as I described in an earlier post on this thread above. The sensor will need a long tip to reach the bull gear through the housing but then all the wiring would be external and this option would sure make it easy to replace a bad sensor.

2. Or attach a small magnet to the top of the gear and a hall effect sensor in the cover above it. This introduces a possible balance issue. But I could always add a counter weight at 180 degrees. This will require internal wiring, but entire kits are available off the shelf for $30 - nothing to do but hook it up.

3. Or an optical sensor similar to what

@whydontu described. But the entire bull gear area is packed with grease and I don't think grease and optical sensors will like each other very much. Also, there is no place for a shutter style window so it would have to be reflector style.

Or.....???

Prolly because of my automotive career I am leaning heavily toward using the engine sensor. Most of all, I like the reliability and the high resolution.

Anyway, it looks to me like it's nowhere near the ugly problem I originally thought it was going to be and installing a sensor shouldn't be that difficult after all. It's just a matter of making a good decision.

The electronics should not be too hard either. I do love the idea of using an Arduino, if for no other reason than the opportunity to learn how to use one! But I'm a bit worried about the speed limits because there are 81 teeth on the bull gear. At 4500 rpm (max Spd on the varispd dial), that's a counting frequency of 364,500 pulses per minute or 6,075 pulses per second (6KHz) which might be too fast for the arduino. Even if it is, that doesn't really matter. I'll use one if I can, and if not there are lots of single chip counters that can be used to generate an extremely accurate tach readout. I'd even bet I already have a few highspeed counter chips already in my electronics supplies.

THE FOLLOWING IS PURE SPECULATION BY A TOTAL IDIOT WHO NEVER USED AN ARDUINO BEFORE BUT WHO HAS USED MICROCONTROLLERS.

I confess that I am a little surprised that there are any concerns about the frequency limits of the Arduino Nano. It just doesn't seem reasonable that any microcontroller might not be able to follow a high frequency input. With a clock frequency of 16MHz, most microcontrollers can follow an 8MHz input, and 4MGz should be easy. So I did a little Arduino research this morning. Apparently, the Arduino IDE does not provide documented access to the full capabilities of the Atmega328P microcontroller itself. So I checked on the capabities of the microcontroller chip. As I had guessed it seems to have 5 hardware timers right on the chip that can be configured as an 8 or 16-bit TC with two compare/capture channels or one 32-bit TC with two compare/capture channels by using two TCS. It also has four 24-bit Timer/Counters for Control (TCC). All are rated at half the clock frequency (ie 8MHz).

So, unless I am all wet AGAIN, it ought to be possible to have the program setup and use a hardware counter (no additional code required except for setup) to count gear tooth pulses until it hits 81 (or any arbitrary higher or lower number, then increment an rpm counter or some such equivalence. A 20 pulse timer would prolly be accurate enough and would make it possible to calculate a high resolution rpm output that is refreshed at a decent rate (say once every 5 seconds). A hardware timer would eliminate the need for software to check the sensor state.

@whydontu - have you tried outputting an on/off pulse on one of the digital outputs from within your measurement loop to see how fast your program really is?

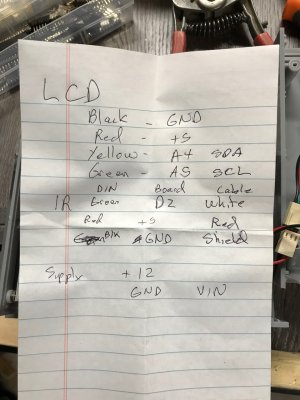

I also gather that the Nano board has to have some pin straps soldered to it before it can be inserted into the Nano Project Board but that the Nano Project Board makes wiring a lot easier after that. This seems really odd. Why wouldn't the Nano board come with the pins already on it? Or is that already an option I didn't see? Or maybe I just missed something....... I did notice that some of the photos had the pins and some didn't.

Is that display the brightest one available? Generally, I need reading glasses for such things so big bright digits are always a blessing. I saw some bright blue and bright green displays on the universal-solder website. But that could be just the photo or web image not the true size and brightness.

I plan to order a set of parts to play with once I get answers to the questions above.

Sorry for all the dumb questions.

And sorry in advance for prolly not replying AGAIN for a few days.......