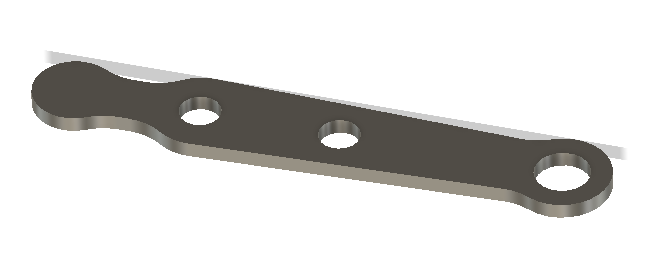

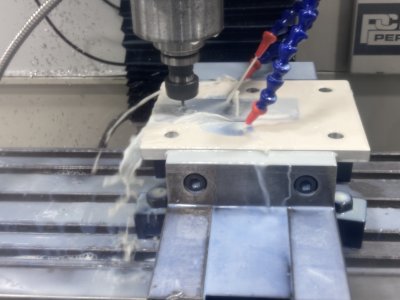

I want to mill some pretty small sheet metal parts ( 1.25" long , up to 3/8" wide and from 0.032" sheet stainless (unknown pedigree).

I tried the painters tape with super glue between them, but it started to let go cause of coolant.

I saw a video by Datron, they used vacuum but said won't work on small parts (not enough area), but then in comments they mention using hot melt glue.

Tried that too and it worked for the first part, but by the time I got to the second it too let go. I think I'm missing a few details with how I applied the glue and the part.

For my next attempt I'm trying epoxy. Any better ideas?

I want to use coolant for the stainless steel.

tapping hold down holes - not super interested as 2 holes are 3/32" , end one is 1/8".

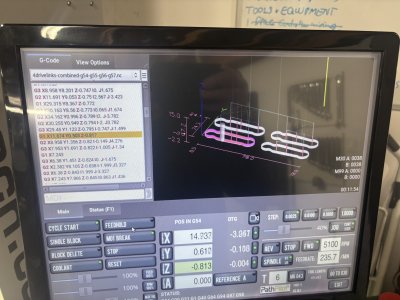

I only need 4 pieces, but this is a learning experience. I regularly need something like this and need to find a better way. Having the part come undone halfway through a program is un-nerving me.

I tried the painters tape with super glue between them, but it started to let go cause of coolant.

I saw a video by Datron, they used vacuum but said won't work on small parts (not enough area), but then in comments they mention using hot melt glue.

Tried that too and it worked for the first part, but by the time I got to the second it too let go. I think I'm missing a few details with how I applied the glue and the part.

For my next attempt I'm trying epoxy. Any better ideas?

I want to use coolant for the stainless steel.

tapping hold down holes - not super interested as 2 holes are 3/32" , end one is 1/8".

I only need 4 pieces, but this is a learning experience. I regularly need something like this and need to find a better way. Having the part come undone halfway through a program is un-nerving me.