-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bandsaw out feed table.

- Thread starter Janger

- Start date

RobinHood

Ultra Member

There might be another aspect to why most of us are trying to improve these saws: if the raw stock we use was only $0.10/lb, I bet many would not hesitate to just lob off a piece and call it good. As long as the cut is better than what a beaver would do, we’d be happy. If the stock then becomes too short, it would be a “hobby drop“: a little cousin to the kind of stuff we‘re all after from a machine shop, or the scrap yard (in the days when it was still allowed to scavenge in them). But since that is not the case (the price is high), even a short piece is turned into something useful, necessitating a band saw to be way more than what it was designed to be... a “precision cutting tool”. Don’t get me wrong, absolutely nothing wrong with improving something and making it safer as well. I for one have spent quite some time to align the blade guide rollers to be just so, and the CI jaws, so that I get a nice, straight cut.

Good link Hruul. That is precisely what I was contemplating. He has a very good idea there with integral jack screw out near the opposite end to help balance the unequal jaw pressure cutting short stubby lengths.

Lots of times Ive had to cut something of 'high value' in the saw. Like a thick section part that has seen hours of lathe/mill work but no good way to part it off in the lathe. Another trick there is to grip the entire chuck in the saw vise with part in the chuck jaws. I dont like the swarf getting up inside the jaws though.

Lots of times Ive had to cut something of 'high value' in the saw. Like a thick section part that has seen hours of lathe/mill work but no good way to part it off in the lathe. Another trick there is to grip the entire chuck in the saw vise with part in the chuck jaws. I dont like the swarf getting up inside the jaws though.

Attachments

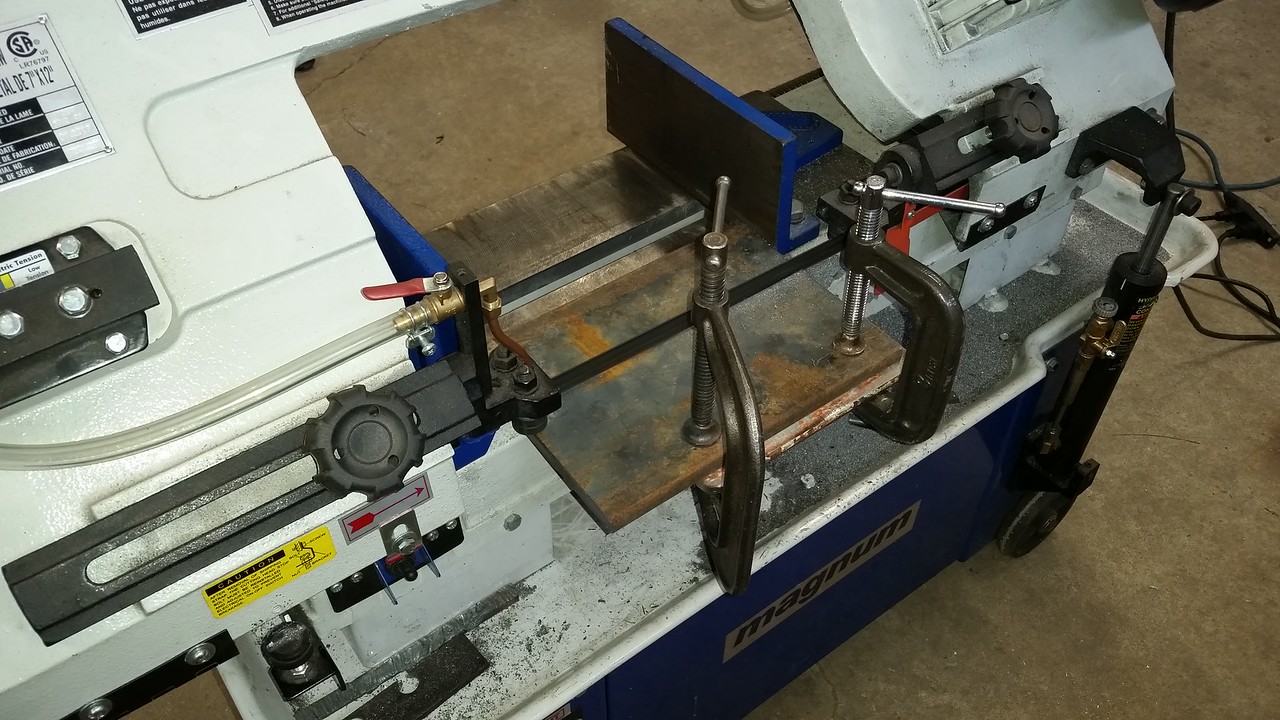

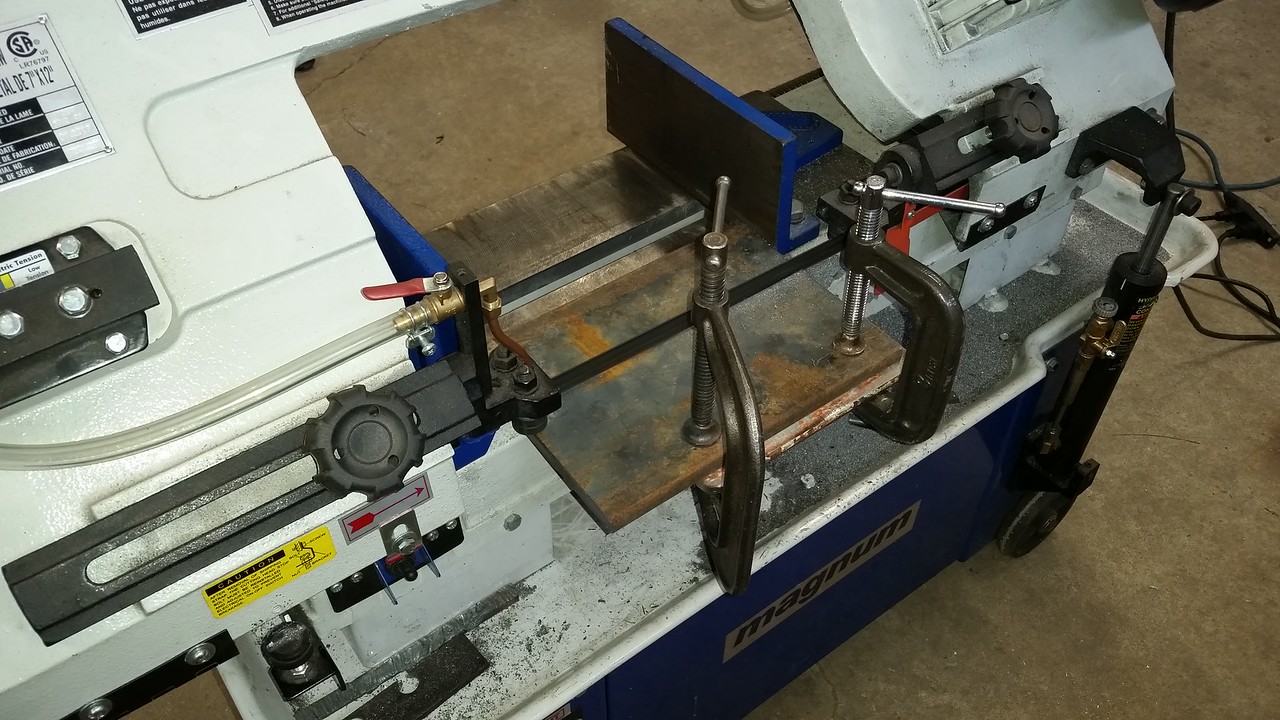

Here's my version of Janger's outfeed table. Pretty much a straight copy except for a couple of details. I used 3" X 3" X 1/4" angle too but to compensate for the angle of the saw casting I measured the gap at the top when the saw and the part were aligned. It was a little less than 1/8" so I button welded a piece of 1/8" X 1/2" flat bar to the table and by trial and error whittled it's thickness down until the alignment was spot on.

While I was at saw improvements I decided to add some of the mods shown in the links above. I have a piece of 1/2" X 7" hot rolled plate left over from another job so I used the new outfeed table to hold a couple of pieces length wise to rip them down to 4" wide, the same dimension as the jaws on my saw.

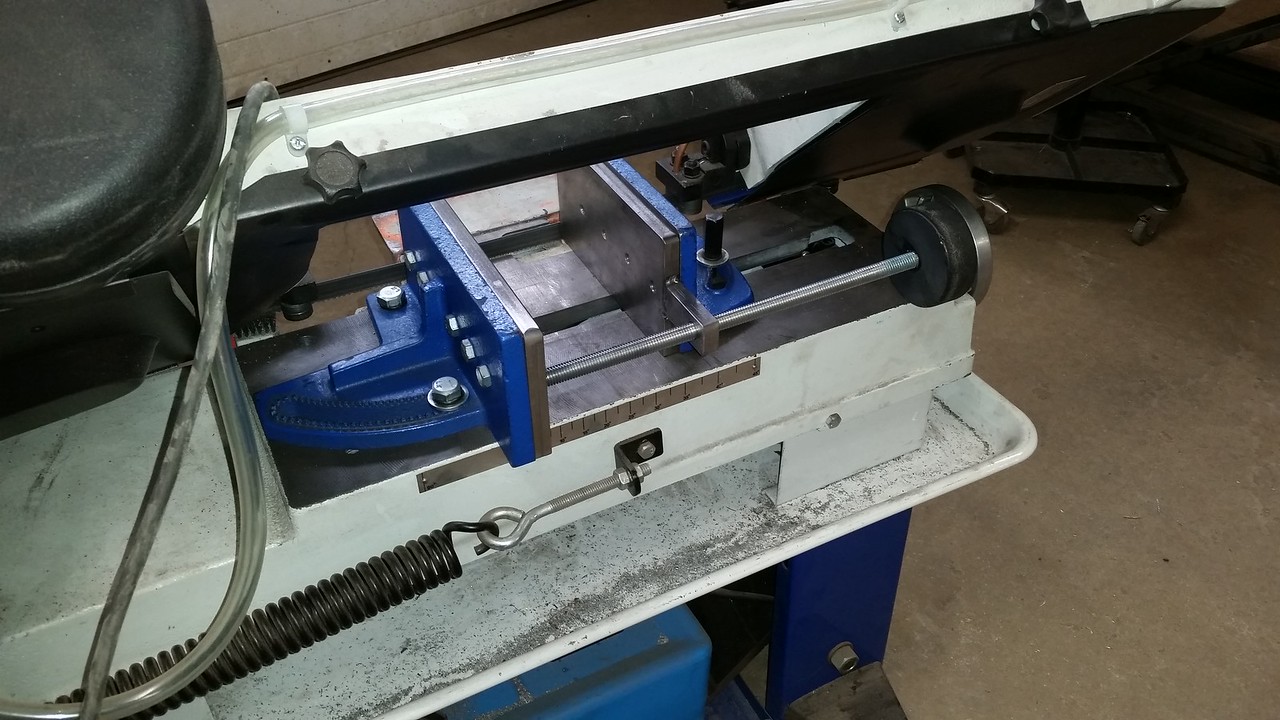

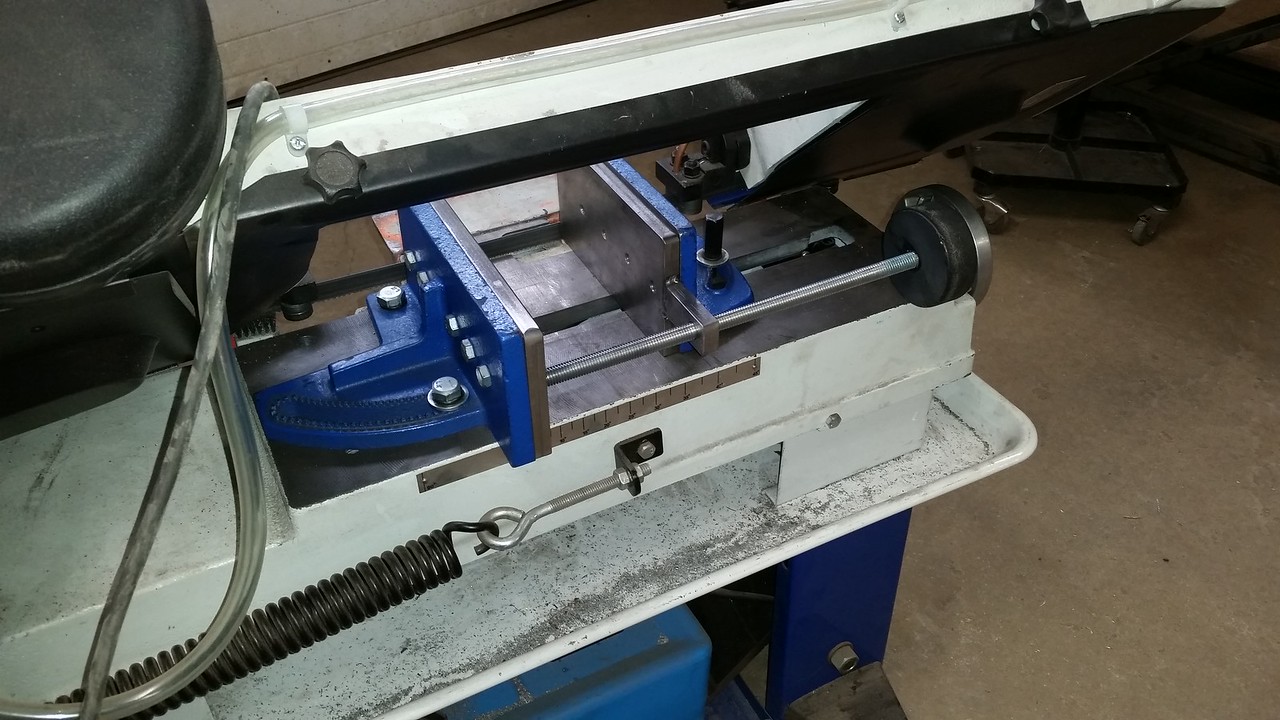

I drilled some 3/8" holes in both jaws and transfer punched, drilled and tapped corresponding holes in my extension jaws. I welded a tab on the movable jaw extension and tapped it to 1/2" 13tpi for the jacking screw. The jaw extensions are 1/4" from the blade when installed and work great for holding short pieces.

For the jacking screw I used a piece of 1/2" all thread rod and made a grip handle for it from a hockey puck. I drilled and tapped the center of the puck to 1/2" 13tpi and used Gorilla glue to bond it to the treads on the rod.

I drilled some 3/8" holes in both jaws and transfer punched, drilled and tapped corresponding holes in my extension jaws. I welded a tab on the movable jaw extension and tapped it to 1/2" 13tpi for the jacking screw. The jaw extensions are 1/4" from the blade when installed and work great for holding short pieces.

For the jacking screw I used a piece of 1/2" all thread rod and made a grip handle for it from a hockey puck. I drilled and tapped the center of the puck to 1/2" 13tpi and used Gorilla glue to bond it to the treads on the rod.

Last edited:

I really like the idea of the permanently attached table.Here is a video showing some mods that one guy did to his bandsaw, including the outfeed table and the longer jaws.

Excellent! Its how these saw jaws should have been designed to begin with. Although I get it - they assumed blade standoff was required when the jaws swivel for miter cuts. But 99% of my cuts are lopping off perpendicular so I'd rather have the jaws close. And because the plates are are bolt on/off its best of both worlds.

Unnecessary frill but this threaded portion could benefit from a quick nut (is that what they are called?). Only reason I mention is I was looking for similar hardware for another project & couldn't find them. Anybody know of a source? They would be a pita to make.

I think John has 700 hockey pucks to use up & this is application number 394! Great idea.

Unnecessary frill but this threaded portion could benefit from a quick nut (is that what they are called?). Only reason I mention is I was looking for similar hardware for another project & couldn't find them. Anybody know of a source? They would be a pita to make.

I think John has 700 hockey pucks to use up & this is application number 394! Great idea.

Attachments

That was my last puck and I had to find a use for it! lol I like the quick nut idea.

Last edited:

Tom Kitta

Ultra Member

I finished my bandsaw project of adding a fence to it. About 90min of video. Total is 9 parts. Here is part 1, 2 and 3. Just change the title number all the way to 9:

Imagine that these 9 parts are all 1Gb of data each plus source video - these guys posting stuff online must have huge data storage resources. Google data centers must be able to store enormous amounts of data.

Imagine that these 9 parts are all 1Gb of data each plus source video - these guys posting stuff online must have huge data storage resources. Google data centers must be able to store enormous amounts of data.

Its great you are posting videos Tom. Wow, multi-tasking between machines.

Sooner or later I'm going to venture into YouTube/video format (15 years after its a 'thing' haha). Nothing serious, just to utilize movie clips as another dimension to convey information above photo & text. My biggest thing is figuring out a video editor. I'm watching some how-to learning on PS Elements. Was setting up your account & uploading straightforward? Or maybe you should start a 'how to become a Youtube celebrity' post. Maybe others have some input & learnings on that front. I don't even watch TV anymore. Youtube channels are my go-to source.

Sooner or later I'm going to venture into YouTube/video format (15 years after its a 'thing' haha). Nothing serious, just to utilize movie clips as another dimension to convey information above photo & text. My biggest thing is figuring out a video editor. I'm watching some how-to learning on PS Elements. Was setting up your account & uploading straightforward? Or maybe you should start a 'how to become a Youtube celebrity' post. Maybe others have some input & learnings on that front. I don't even watch TV anymore. Youtube channels are my go-to source.

Tom Kitta

Ultra Member

I used OpenShot editor - it is a free little editor. There are lots of functions but I mostly just stitch together stuff and add few pictures. There are like dozens of cool transitions available and maybe even some other cool stuff. It takes a long time to edit a video even in such basic fashion, over 10min to create output and over 10 min to upload it.

Bonus points for the video work Tom. Nicely done.I finished my bandsaw project of adding a fence to it. About 90min of video. Total is 9 parts. Here is part 1, 2 and 3. Just change the title number all the way to 9:

Imagine that these 9 parts are all 1Gb of data each plus source video - these guys posting stuff online must have huge data storage resources. Google data centers must be able to store enormous amounts of data.