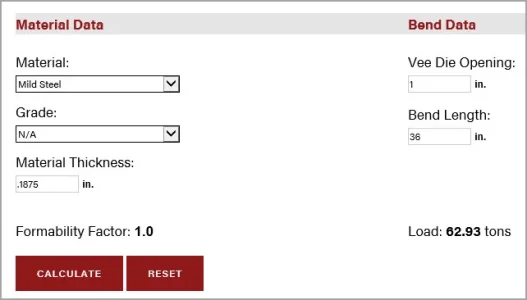

I need to make some 90 degree bends in ~3' lengths of ~3/16" steel, maybe less thick, but in that area.

Hoping someone has a brake long enough!

I'll come prepared with steel all laid out, need to make about 12 bends total.

Cell: (40)3 617 3364

Text me or call after 5:00!

Alternatively, shoot me your number and I'll call you!

Hoping someone has a brake long enough!

I'll come prepared with steel all laid out, need to make about 12 bends total.

Cell: (40)3 617 3364

Text me or call after 5:00!

Alternatively, shoot me your number and I'll call you!