Welcome from Ottawa, lots of good info on here and great people.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another person infected with the habit ... from Burlington

- Thread starter Aarknoid

- Start date

Lakeside machinery

Member

I'm just up the road in milton.I think I am in the right place,

Hello, my name is Mark ... and I have a problem, I have started a home for wayward machines and have delusions of becoming a home machinist.

Am a controls tech by trade so i figured, why not do work at home, but for free

So far i have most of the parts of an old Colchester ( technically B.I.E ) Student and a PDM-30 in the stable.

I keep ending up back here while searching the net for information, figured it was time to surface

o/

Lakeside machinery

Member

I have a colchester mk1 12×24 student from 1954. Currently in pieces getting repaired repainted once the weather gets warmer. Also have a brown and sharpe no2 surface grinder from around 1910s and a sajo uf52 horizontal mill. All at the cottage though as that's where I have spaceI'm just up the road in milton.

Attachments

Blouin55

Michel

Mince looking pièces. I like them!I have a colchester mk1 12×24 student from 1954. Currently in pieces getting repaired repainted once the weather gets warmer. Also have a brown and sharpe no2 surface grinder from around 1910s and a sajo uf52 horizontal mill. All at the cottage though as that's where I have space

Blouin55

Michel

Nice..Mince looking pièces. I like them!

Aarknoid

Super User

If yo are ever inside the quick change gear box, if you could take a peak at the bottom gear shaft.. could you have a look to see if there is a twist?I have a colchester mk1 12×24 student from 1954. Currently in pieces getting repaired repainted once the weather gets warmer. Also have a brown and sharpe no2 surface grinder from around 1910s and a sajo uf52 horizontal mill. All at the cottage though as that's where I have space

I posted a pic of mine and I have a hard time believing that the shaft on mine got bent as it did without absolutely destroying everything else

Lakeside machinery

Member

Did you have a problem shifting the D-C lever? If so, I had the same problem. I was lucky enough to find a shaft on Ebay (I think very lucky). I think its called the drivin shaft. It happens when someone crashes the lathe while threading and hasn't used the correct shear pin in the change gear driving gear. If it's too hard (someone put a roll pin in mine) it won't give. This won't happen in the feed drive because that shaft has a spring loaded ball clutch that'll just slip. I did have to add a bronze washer on the shaft I installed as it wasn't a perfect fit. Mine also has a cracked half nut sliding shaft that can make you crash when trying to kick it out on a heavy cut. (Ask me how I know) It wouldn't release until I reversed the spindle. As I said, mine was twisted to the point that the gear was jammed in the D position. I've got half of the lathe here in milton(well the saddle, apron,gear cover, tail stock etc. The bed and head stock are at the cottage.If yo are ever inside the quick change gear box, if you could take a peak at the bottom gear shaft.. could you have a look to see if there is a twist?

I posted a pic of mine and I have a hard time believing that the shaft on mine got bent as it did without absolutely destroying everything else

Lakeside machinery

Member

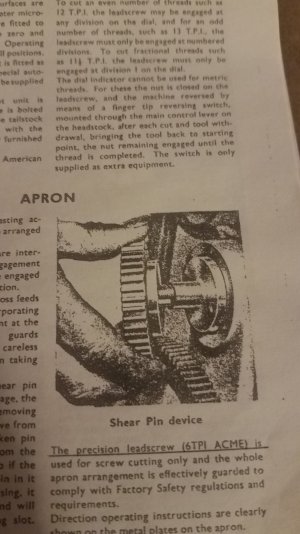

Here is the gear driving the change gears. As you can see, the holes in the bushing are where you install the shear pin. As you can see, mine has been chowdered up even before I got it. There is the location picture from the manual

Attachments

Lakeside machinery

Member

Lakeside machinery

Member

The mill is working but could use a clean up, the lathe was bought with the quick change gear box disassembled with a supposedly bent pinion in it ,

oh and a missing motor, which i have acquired but haven't mounted yet

That's way more twisted than mine was. I think I still have mine up north. It's almost not noticeable on mine. You may have better luck repairing the one I have if you know someone to do it. Like I said in your other post my sliding gear would jam part way though. If you want, I'll bring it back with me next time I go up in a few weeks.The mill is working but could use a clean up, the lathe was bought with the quick change gear box disassembled with a supposedly bent pinion in it ,

oh and a missing motor, which i have acquired but haven't mounted yet

Lakeside machinery

Member

I'm planning on milling and grinding the dovetails on the saddle ways, cross slide and compound dovetails. They both get tight in parts of their travel and my initial measurements show up to 12thou wear in the flat way in the bottom of the saddle. I'll know better in a few months once I pickup a surface plate big enough to measure it properlyMince looking pièces. I like them!

Lakeside machinery

Member

The mill is working but could use a clean up, the lathe was bought with the quick change gear box disassembled with a supposedly bent pinion in it ,

oh and a missing motor, which i have acquired but haven't mounted yet

I was lucky enough in that way. My brown and sharp showed up on kijiji for free to the first one to pick it up. Luckily I was in the area with a dump truck and skidsteer in the trailer. I was so thankful, I helped him move the other equipment he had gotten in that lot into position in his shop sa the machinery movers just dropped everything outside on the drivewaywelcome from Toronto.

You are situated within some of the most densely populated machine tool habitat in Canada. IF you are prepared, you can beat most people to the punch anywhere within this map and acquire a wayward machine tool before others have even caught scent of the prey.

View attachment 21138

Former Member

Guest

Poor soul!

deleted_user

Super User

Yeah, it is confirmed... I hate youI was lucky enough in that way. My brown and sharp showed up on kijiji for free to the first one to pick it up. Luckily I was in the area with a dump truck and skidsteer in the trailer. I was so thankful, I helped him move the other equipment he had gotten in that lot into position in his shop sa the machinery movers just dropped everything outside on the driveway

Lakeside machinery

Member

My luck has dwindled massively since. Maybe payback lolYeah, it is confirmed... I hate you

Aarknoid

Super User

Ah, so you might know where kilbride is ! no one else doesWelcome from Calgary, frrom a former Birlingtonian.

Also a wayward machine collector - but trying to reform into machine rebuilder.

Lakeside machinery

Member

Yes, head through there if I take my wife to work in Burlington. Nice little spot. Cedar springs rd I thinkAh, so you might know where kilbride is ! no one else does