-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

- Home

- Forums

- Buy and Sell, Deals Spotted, and Help Required

- Request a part, job, or quote from members

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

YYC - Resurface turbo exhaust manifold

- Thread starter digitalbilly

- Start date

-

- Tags

- small job

digitalbilly

Member

just some info here

Total length 59cm

Maximum warpage: 0.40 mm (0.0157 in.)

Total length 59cm

Maximum warpage: 0.40 mm (0.0157 in.)

Former Member

Guest

As long as you have a straight surface you can do it by hand more than enough to bring it in true for the intended purpose.

digitalbilly

Member

As long as you have a straight surface you can do it by hand more than enough to bring it in true for the intended purpose.

I have thought about that by using a piece of glass and some sandpaper. I currently do not have a surface flat enough.

Former Member

Guest

Glass is great, table saw also, kitchen counter when wife is not around.I have thought about that by using a piece of glass and some sandpaper. I currently do not have a surface flat enough.

Former Member

Guest

Just do

.

.

Just don't get caughtGranite countertop came to mind like Degen suggests.

I have milled a number of manifolds, but before I had a mill I replaced the exhaust manifold gasket on my 2003 Dodge 2500 Hemi I used to own. I used my belt sander and some fairly rough belts (60 to 80 grit or so) and checked against a straightedge as I went. So yes, a belt sander does work to get the warpage out too. From your measurements it sounds like your manifold shouldn't need too much working compared to the 5.7 Hemi manifolds. I did a pair of them a week and a half ago and one needed .060" milled to straighten it, the other .050" off.

Everett did your exhaust manifold on the hemi have multiple flanges similar to digitalbilly? is it critical that all the flanges are on the exact same plane or will the gasket even it out?I have milled a number of manifolds, but before I had a mill I replaced the exhaust manifold gasket on my 2003 Dodge 2500 Hemi I used to own. I used my belt sander and some fairly rough belts (60 to 80 grit or so) and checked against a straightedge as I went. So yes, a belt sander does work to get the warpage out too. From your measurements it sounds like your manifold shouldn't need too much working compared to the 5.7 Hemi manifolds. I did a pair of them a week and a half ago and one needed .060" milled to straighten it, the other .050" off.

@Janger - the Chrysler 5.7 Hemi manifolds each have 4 individual flanges, nothing Siamesed like an old school Chev 350 manifold. I found from experience that once you get them all into about the same plane they are fine from then on. The outer ones warp away from the heads, breaking the bolts off, and giving the "Hemi exhaust tick."

The manifolds from new are fresh castings that just get machined and put on an engine. They don't "season" them, the metal casting stresses come out over time with heat/cool cycles. And, for what it's worth, they will still seal for a bit even with just replacing the gaskets and slapping them back on, the only issue is that over time they will pop the manifold bolts off yet again. Anyone who has had a manifold gasket done on warranty will have a 95% chance the original, warped, manifold will have been reinstalled, as-is. And the same problem will happen again, but the warranty clerk and service manager generally don't care. If you even just use a belt sander to take the cold manifold flanges to pretty much the same plane you won't have the bolt-breaking problem again. We're not talking AA surface plate flatness here, even using the side of a yard stick will be good enough. Exhaust gaskets give a little bit of wiggle room.

In looking at the picture, I would have to agree with @phaxtris if I had to make a guess - 8.3 Cummins? Reason I am guessing that too is that I've done an 8.3 manifold as well, a couple years ago, for a grain truck that came in the truck shop.

The manifolds from new are fresh castings that just get machined and put on an engine. They don't "season" them, the metal casting stresses come out over time with heat/cool cycles. And, for what it's worth, they will still seal for a bit even with just replacing the gaskets and slapping them back on, the only issue is that over time they will pop the manifold bolts off yet again. Anyone who has had a manifold gasket done on warranty will have a 95% chance the original, warped, manifold will have been reinstalled, as-is. And the same problem will happen again, but the warranty clerk and service manager generally don't care. If you even just use a belt sander to take the cold manifold flanges to pretty much the same plane you won't have the bolt-breaking problem again. We're not talking AA surface plate flatness here, even using the side of a yard stick will be good enough. Exhaust gaskets give a little bit of wiggle room.

In looking at the picture, I would have to agree with @phaxtris if I had to make a guess - 8.3 Cummins? Reason I am guessing that too is that I've done an 8.3 manifold as well, a couple years ago, for a grain truck that came in the truck shop.

digitalbilly

Member

Not quite. It’s a turbo manifold for 1991 Land Cruiser 80 series turbo dieselMost engine shops can resurface that manifold for you, pretty standard item. I can't help, my mill isn't big enough

Looks like a Cummins manifold ?

Former Member

Guest

This...is the winner statement.We're not talking AA surface plate flatness here, even using the side of a yard stick will be good enough. Exhaust gaskets give a little bit of wiggle room.

.

digitalbilly

Member

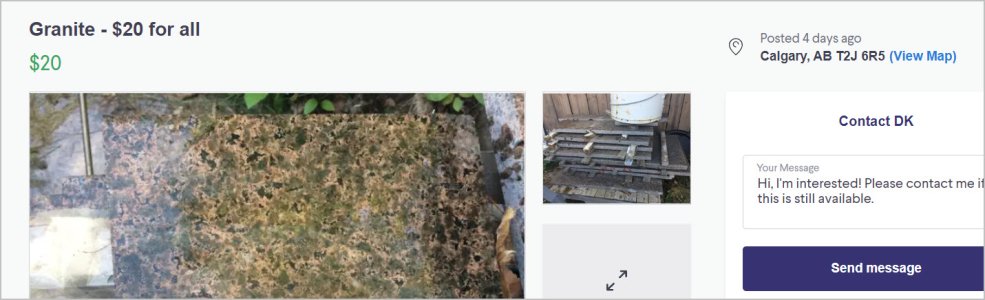

Arg gone! thanks for checking.Well you could get a granite drop probably cheap from a counter installer. You know there was one down the alley it was 5’ long. I’ll go see if it’s still there.

EDIT -> Nope it's gone.

I guess the best bet would be to see if I can find a piece free or cheap next to nothing.

Kijiji might have some prospects that meet your length requirements. The trick is how flat is flat for your requirements. Some of the granite shops might have skinny offcuts useless for them but perfect for you. Or be able cut a slab you acquired elsewhere. Countertop granite is polished on the glossy side vs ground matte like a surface plate, so it may not take on 'blue' if you were looking to transfer where the high (contact) areas were. But maybe there are other workarounds.

I've shimmed recycled glass bookshelves to be sufficiently accurate for other applications & they come in convenient aspect ratios for your need, but maybe not as forgiving a surface.

I've shimmed recycled glass bookshelves to be sufficiently accurate for other applications & they come in convenient aspect ratios for your need, but maybe not as forgiving a surface.

Attachments

Former Member

Guest

Look a sheet of 3/4" MDF on a floor can work just as well. Lay a belt of sandpaper on it and go at it. Remember you are trying to clean it up and get it within a couple of thou...

There are a couple of YouTube videos out there of guys doing ghetto cylinder heads that way.

Remember the perfect tools make it easier, but a good machinist can do it with the any tools at hand and get the required results.

Think out side the box, even better use the box.

There are a couple of YouTube videos out there of guys doing ghetto cylinder heads that way.

Remember the perfect tools make it easier, but a good machinist can do it with the any tools at hand and get the required results.

Think out side the box, even better use the box.

Last edited:

On my first big truck the exhaust manifold was 2 or 3 pieces (don’t remember) with Cummins probably trying to build in a joint to allow some flex. Don’t ask me why but I had to buy a new short end piece (again, don’t remember the reason), they sent it out to get machined because of the number of mating surfaces that needed to line up. They machined a few reference points and clamping points, before committing to doing the flanges.@Janger - the Chrysler 5.7 Hemi manifolds each have 4 individual flanges, nothing Siamesed like an old school Chev 350 manifold. I found from experience that once you get them all into about the same plane they are fine from then on. The outer ones warp away from the heads, breaking the bolts off, and giving the "Hemi exhaust tick."

The manifolds from new are fresh castings that just get machined and put on an engine. They don't "season" them, the metal casting stresses come out over time with heat/cool cycles. And, for what it's worth, they will still seal for a bit even with just replacing the gaskets and slapping them back on, the only issue is that over time they will pop the manifold bolts off yet again. Anyone who has had a manifold gasket done on warranty will have a 95% chance the original, warped, manifold will have been reinstalled, as-is. And the same problem will happen again, but the warranty clerk and service manager generally don't care. If you even just use a belt sander to take the cold manifold flanges to pretty much the same plane you won't have the bolt-breaking problem again. We're not talking AA surface plate flatness here, even using the side of a yard stick will be good enough. Exhaust gaskets give a little bit of wiggle room.

In looking at the picture, I would have to agree with @phaxtris if I had to make a guess - 8.3 Cummins? Reason I am guessing that too is that I've done an 8.3 manifold as well, a couple years ago, for a grain truck that came in the truck shop.

Way above my pay grade but it turned out nice

digitalbilly

Member

Ok sounds good think “outside the box”. Me being super newb here what sand paper grits should I start and finish with? I have feeler gauges and a precision strait edge for checking Cylinder heads and engine blocks. Basically follow this technique ResurfaceLook a sheet of 3/4" MDF on a floor can work just as well. Lay a belt of sandpaper on it and go at it. Remember you are trying to clean it up and get it within a couple of thou...

There are a couple of YouTube videos out there of guys doing ghetto cylinder heads that way.

Remember the perfect tools make it easier, but a good machinist can do it with the any tools at hand and get the required results.

Think out side the box, even better use the box.

Last edited:

digitalbilly

Member

Perfect thanks.Kijiji might have some prospects that meet your length requirements. The trick is how flat is flat for your requirements. Some of the granite shops might have skinny offcuts useless for them but perfect for you. Or be able cut a slab you acquired elsewhere. Countertop granite is polished on the glossy side vs ground matte like a surface plate, so it may not take on 'blue' if you were looking to transfer where the high (contact) areas were. But maybe there are other workarounds.

I've shimmed recycled glass bookshelves to be sufficiently accurate for other applications & they come in convenient aspect ratios for your need, but maybe not as forgiving a surface.

![IMG_2357[1].JPG IMG_2357[1].JPG](https://canadianhobbymetalworkers.com/data/attachments/34/34612-f199e383f7b498672238d3f8e4cd1537.jpg?hash=_LYB6qqVbe)

![IMG_2359[1].JPG IMG_2359[1].JPG](https://canadianhobbymetalworkers.com/data/attachments/34/34610-ad274a998b2285139f08cf52ea11086f.jpg?hash=4IwPKvN6A5)

![IMG_2358[1].JPG IMG_2358[1].JPG](https://canadianhobbymetalworkers.com/data/attachments/34/34609-8b2ccf97935658e37224103c78810a9e.jpg?hash=MlE4VvKtwB)