calgaryguy

Chris

"Yet Another Standard Modern (9") Thread"

My former-SAIT Standard-Modern 9" Utilathe came with a 3ph 1/3hp 1725rpm motor. I've replaced it with a 3/4hp Baldor single phase 1800rpm motor.

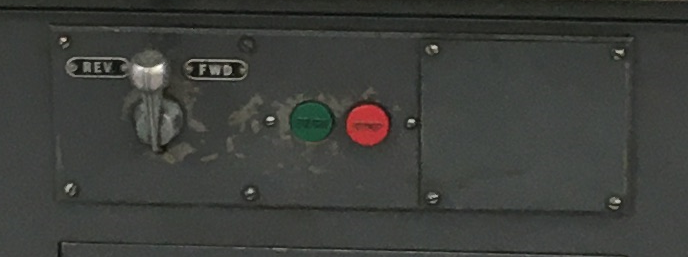

The SM base has a control panel with on/off buttons and a fwd-rev switch

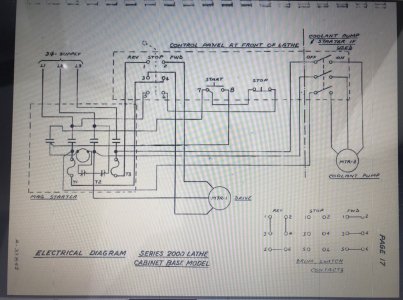

All good, @YYCHM provided a wiring diagram from the manual showing how to wire the front control panel for 220v 1ph.

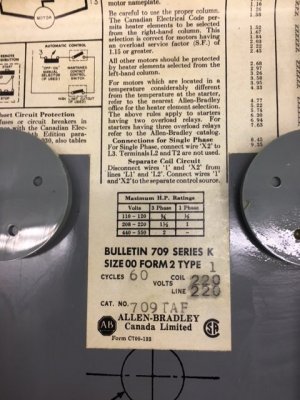

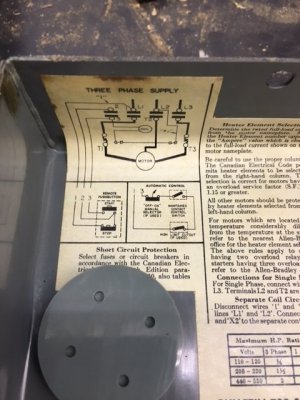

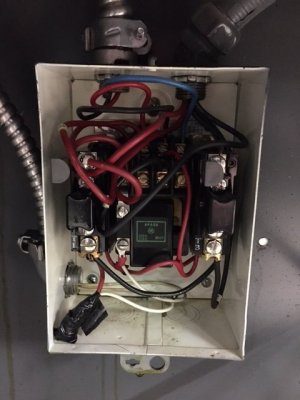

My challenge now is wiring the Allen Bradley Mag switch located inside the cabinet

I've googled for "allen bradley 709 taf" with no luck. Is there anyone out there familiar with these mag switches or knows of a internet resource with AB manuals? I know modern mag switches are usually 1ph and 3ph capable depending on how they are wired. Are these older AB mag switches the same?

My former-SAIT Standard-Modern 9" Utilathe came with a 3ph 1/3hp 1725rpm motor. I've replaced it with a 3/4hp Baldor single phase 1800rpm motor.

The SM base has a control panel with on/off buttons and a fwd-rev switch

All good, @YYCHM provided a wiring diagram from the manual showing how to wire the front control panel for 220v 1ph.

My challenge now is wiring the Allen Bradley Mag switch located inside the cabinet

I've googled for "allen bradley 709 taf" with no luck. Is there anyone out there familiar with these mag switches or knows of a internet resource with AB manuals? I know modern mag switches are usually 1ph and 3ph capable depending on how they are wired. Are these older AB mag switches the same?

Last edited: