-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WTB - Tapping Head

- Thread starter YYCHM

- Start date

I realize this will go over like a lead balloon but I have to say it anyway.Ideally it would....

Tap up to 1/2"

Have R8 or 3/4" straight shank

Be auto reversing

I'll consider anything actually...

PM me if you have something to part with.

Thanks,

Craig

G90 (set absolute mode)

G0 X1.000 Y1.000 Z0.100 (rapid move to starting position)

S100 M3 (turn on the spindle, 100 RPM)

G33.1 Z-0.750 K0.05 (rigid tap a 20 TPI thread 0.750 deep)

M2 (end program)

Here's a detailed explanation.

Looking for a video...

Here we go. Into oak. I had posted it to youtube.

Last edited:

Be prepared to pay 3 to 4 times that for converting to CNC but it's soooooooo much fun.@YYCHM for a tapmatic, be prepared to pay 275$ - 300$ USED.

Former Member

Guest

I have a head and love it, up to 1/2" can get a little more expensive. Consider new as the clutches and components can be hard to replace.

When I start tapping on the CNC I'm going to use a end mill for cutting threads and a threading routine. Better flexibility.

When I start tapping on the CNC I'm going to use a end mill for cutting threads and a threading routine. Better flexibility.

Shars makes clones but no idea if they are any good.

www.shars.com

www.shars.com

Tapping Heads & Accessories

Shop Shars Tool today and see why customers choose our high quality tapping heads at a great value, same-day shipping, and dedicated customer support.

Looking forward to seeing that approach for 4-40 or 6-32 threaded holes.I have a head and love it, up to 1/2" can get a little more expensive. Consider new as the clutches and components can be hard to replace.

When I start tapping on the CNC I'm going to use a end mill for cutting threads and a threading routine. Better flexibility.

Tom Kitta

Ultra Member

I have three tapping heads. Usually they come in sizes. I.e. you cannot tap on the same head, AFAIK, which can do tiny thread like 4-40 and a large one like 1/2-13 with same adjustable head.

Personally I have most use only for tapping heads that are in the small range - i.e. threads 5/16 and under - anything 3/8 and over especially far a pass through hole can by tapped easily without tapping head - just put the tap in, use it, reverse your mill and out it comes. Unless material is hard like 4330 and tap is dull breaking it off are unlikely.

All of my tapping heads are MT - none are for R8 or straight shank - maybe they do have such shanks but to be honest I never seen a tapping head with straight shank.

Personally I have most use only for tapping heads that are in the small range - i.e. threads 5/16 and under - anything 3/8 and over especially far a pass through hole can by tapped easily without tapping head - just put the tap in, use it, reverse your mill and out it comes. Unless material is hard like 4330 and tap is dull breaking it off are unlikely.

All of my tapping heads are MT - none are for R8 or straight shank - maybe they do have such shanks but to be honest I never seen a tapping head with straight shank.

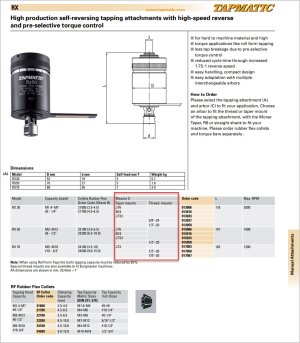

I cant speak for other makes but I know Tapmatic come in a multitude of common arbor mounts. So its easy to just get the appropriate arbor to marry the head to your machine analogous to 2-part drill chucks. Some have the heads dedicated to a drill press, others a mill.

Attachments

Former Member

Guest

Most of the tap heads have removable shanks to allow them to be fitted to whatever spindle is required (no different than a drill chuck).

Tom Kitta

Ultra Member

Most of the tap heads have removable shanks to allow them to be fitted to whatever spindle is required (no different than a drill chuck).

New stuff yes - old stuff seems to be integrated. My old one is like 100 years old.

Anyone have one of these?

accusizetools.com

accusizetools.com

Self-Reversing Tapping Heads

The Accusize tapping head is commonly used as the following tools (and solutions): tapping head, tap holder, morse tapper, JSN-7, JSN-12, JSN-20, JSN7, JSN12, JSN20, tapping head for drill press, tapping head r8, tapping head reversing, tapping head r8 shank, tapping head for hand drill, tapping...

Tom Kitta

Ultra Member

Anyone have one of these?

Self-Reversing Tapping Heads

The Accusize tapping head is commonly used as the following tools (and solutions): tapping head, tap holder, morse tapper, JSN-7, JSN-12, JSN-20, JSN7, JSN12, JSN20, tapping head for drill press, tapping head r8, tapping head reversing, tapping head r8 shank, tapping head for hand drill, tapping...accusizetools.com

Yep I have one of these - small one for small taps, I do not think mine is from Accusize but they all look identical.

You can get them from ali as well.

Yep I have one of these - small one for small taps, I do not think mine is from Accusize but they all look identical.

You can get them from ali as well.

Not seeing much on AliExpress and what's there is on the expensive side?

Former Member

Guest

Yes just under a different brand from KBC years ago.Anyone have one of these?

Self-Reversing Tapping Heads

The Accusize tapping head is commonly used as the following tools (and solutions): tapping head, tap holder, morse tapper, JSN-7, JSN-12, JSN-20, JSN7, JSN12, JSN20, tapping head for drill press, tapping head r8, tapping head reversing, tapping head r8 shank, tapping head for hand drill, tapping...accusizetools.com

Yes just under a different brand from KBC years ago.

Does it work well enough? Any negatives?

Tom Kitta

Ultra Member

Not seeing much on AliExpress and what's there is on the expensive side?

175.36C$ 15% OFF|J467 Tapping Chuck M2 M7 (5/64 1/4) Auto Reversing Tapping Head Reversible Tapping Clamp Drilling Milling Machine Accessories|Power Tool Sets| - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

Its not a big seller & word "tapping" is super popular.

gerritv

Gerrit

I've done M3 on my shop built CNC. Tested in delrin first due to pucker factor on $15 tool. Easy enough to buy down to M1x0.25 (<0-80)Looking forward to seeing that approach for 4-40 or 6-32 threaded holes.

That's why my video was oak. I've done 4mm under CNC. Sure is cool to watch even with the pucker factor.I've done M3 on my shop built CNC. Tested in delrin first due to pucker factor on $15 tool. Easy enough to buy down to M1x0.25 (<0-80)

My biggest worry is that I haven't got the V belts tight enough or that the pulleys I built are not adequate for proper grip and that the belts will slip. Not that it matters as the encoder is on the spindle but I think once slipping starts it's hard to recover.

It's the next size up in link belts and I'm not sure I want to spend the money on that when I really just want to go to a toothed belt. Project #42.