At the meetup we got onto a short discussion on work holding toe clamps and @Stuart Samuel showed me a marketplace add. With his help, thank you Stuart, I followed up on it and Monday I came home with these things:

I got a pair of each of the clamps shown in this pic:

The toe clamp (bottom left, red arrow) is available at KBC for $133.84 each. The pair I got are in near perfect condition.

IMO: I paid a fair price for one of these toe clamps and all the rest of the items were just along for the ride home.

Here’s a better pic of the smaller arm hold downs. They are identical and made in Canada (model 625)

The larger ones (both model 750) are different castings, one made in Canada and one made in USA.

Also got a half dozen smaller hold down arms

Also these (next pic) monster hold down arms. Rather big for me, but man alive, are they ever sweet tuning forks (grandkids will love ‘em)

These stacked 1/8” pieces allow you to easily adjust the height of your support (post) at the opposite end of the hold down arm. Cool - I’ve not seen them before (James Morton made in Canada)

The back pair are 3.75” tall. The front ones are 2” and 3” tall.

In the next pic I have the back two set at 2.75” and the front two set at a height of 1.5”. (In the middle of this pic are a couple of the stepped support posts that came with my bar clamping kit.) They needed some cleaning. They were full of grit and crud when i got them. They work smoothly now after a bath in the ultrasonic cleaner and some oil.

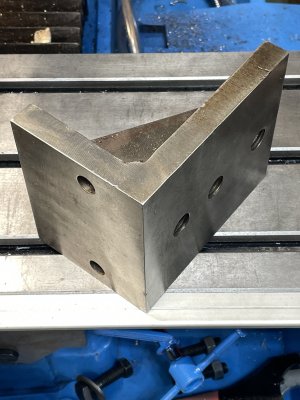

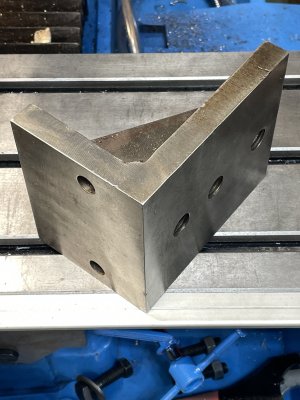

Also included in the haul is this 4-5-6 angle bracket.

www.kbctools.ca

www.kbctools.ca

I got a pair of each of the clamps shown in this pic:

The toe clamp (bottom left, red arrow) is available at KBC for $133.84 each. The pair I got are in near perfect condition.

IMO: I paid a fair price for one of these toe clamps and all the rest of the items were just along for the ride home.

Here’s a better pic of the smaller arm hold downs. They are identical and made in Canada (model 625)

The larger ones (both model 750) are different castings, one made in Canada and one made in USA.

Also got a half dozen smaller hold down arms

Also these (next pic) monster hold down arms. Rather big for me, but man alive, are they ever sweet tuning forks (grandkids will love ‘em)

These stacked 1/8” pieces allow you to easily adjust the height of your support (post) at the opposite end of the hold down arm. Cool - I’ve not seen them before (James Morton made in Canada)

The back pair are 3.75” tall. The front ones are 2” and 3” tall.

In the next pic I have the back two set at 2.75” and the front two set at a height of 1.5”. (In the middle of this pic are a couple of the stepped support posts that came with my bar clamping kit.) They needed some cleaning. They were full of grit and crud when i got them. They work smoothly now after a bath in the ultrasonic cleaner and some oil.

Also included in the haul is this 4-5-6 angle bracket.

TECO,5.3/16X1/2IN NUZZLER EDGE CLAMP LOW GRIP,1-903-33807,KBC Tools & Machinery

TECO,5.3/16X1/2IN NUZZLER EDGE CLAMP LOW GRIP,1-903-33807,KBC Tools & Machinery

Last edited: