Stumbled onto this video. Even if you never want to build one some of the techniques are interesting.

And he gets his deionized water from Cdn. Tire.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire EDM machine

- Thread starter jcdammeyer

- Start date

gerritv

Gerrit

A nice mechanical build but their spark generator was all wrong. I offered advice, as did several other hobby-level experts such as plasmaboog but still waiting on an update. Emails to them get no response.

I want to build one but until I see an affordable generator beyond the very simple rc network I am not starting.

I want to build one but until I see an affordable generator beyond the very simple rc network I am not starting.

Somewhere in my magazine archives, I think it was Model Engineer's Workshop, there was an arcticle where someone built an EDM machine. Mostly for removing broken studs from small engines. His power supply, IIRC, was fairly complex.A nice mechanical build but their spark generator was all wrong. I offered advice, as did several other hobby-level experts such as plasmaboog but still waiting on an update. Emails to them get no response.

I want to build one but until I see an affordable generator beyond the very simple rc network I am not starting.

Edit: I keep forgetting that magazines and usegroups are no longer the place for development. Youtube seems to be the place now to learn how to do something and no need to ask others. A bit more research and this web site showed up.

Last edited:

gerritv

Gerrit

Yes, BAXEDM is great. Except his generator is >2900Eu's :-(

https://tenebryo.github.io/posts/2021-04-07-edm-power-supply.html has a design but doesn't show all of it. I might contact him later this year once I get some other projects completed.

This is along the lines of what I want to eventually build:

https://tenebryo.github.io/posts/2021-04-07-edm-power-supply.html has a design but doesn't show all of it. I might contact him later this year once I get some other projects completed.

This is along the lines of what I want to eventually build:

I first learned about wire EDM when I worked at ASM FICO Trim & Form in The Netherlands. They had machines there that created the punches and dies to trim the leads and the anti-static shorting strip (called a draw bar) from around the device. The tools had very narrow fingers to punch between the IC leads.

This gives an example of just how fine the EDM made the tool and die. Oh and since in the row of machines just before the final stamping by the 30T press we had a laser marker. They put my Dutch address on this lead frame for me.

This gives an example of just how fine the EDM made the tool and die. Oh and since in the row of machines just before the final stamping by the 30T press we had a laser marker. They put my Dutch address on this lead frame for me.

Former Member

Guest

EDM can do this.

Former Member

Guest

If you have enough money, space and power the sky's the limit.

Don't see why not.I have those magazines showing how to make the edm for bolts and was wondering if it could be updated for current electronics.

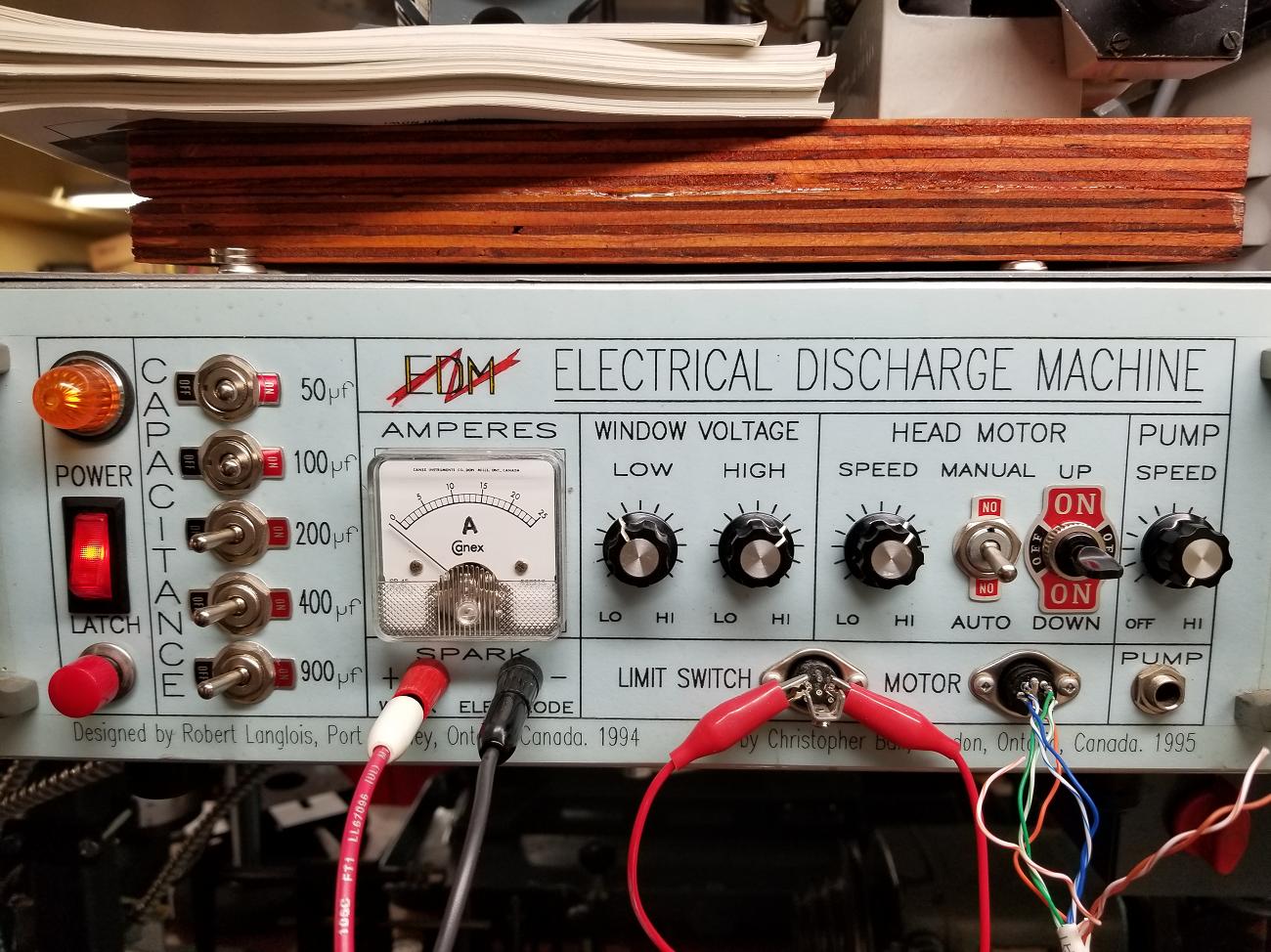

I sanctioned (funded) a build of an edm last year. My partner in crime was given the book by langlois and noted the same thing — dated components. The final product cost me 180cdn and was built with an arduino & some capacitor banks. Fundamentally it “works” but needs fine tuning.I have those magazines showing how to make the edm for bolts and was wondering if it could be updated for current electronics.

I think skies the limits

Got any pictures?I sanctioned (funded) a build of an edm last year. My partner in crime was given the book by langlois and noted the same thing — dated components. The final product cost me 180cdn and was built with an arduino & some capacitor banks. Fundamentally it “works” but needs fine tuning.

I think skies the limits

That's ones I have too. Really wish I wasn't missing the one MEW.I have these ones

View attachment 29653

Hitachi wire EDM for sale in Vancouver

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

Yes, BAXEDM is great. Except his generator is >2900Eu's :-(

My sense from his narrative is the that generator is a bloody hard bit of engineering to get right and he was doing a good deed in making it available that us mere mortals. I really have no idea how true that really is, or how much of a sales pitch it is.

Does anyone pay that? I'd probably be a buyer $700-$800 but 4200 cdn? Even if I could wrap my head around it, I feel likes its too big a commitment to a one man band's technology, i.e. support, service parts etc in the future.

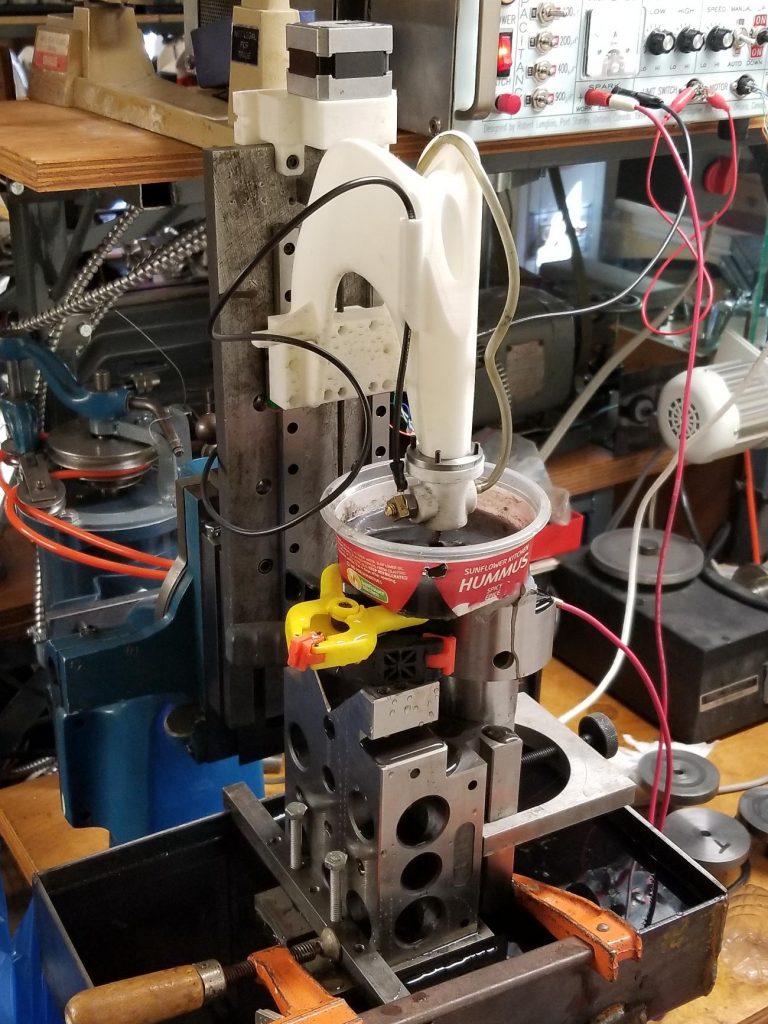

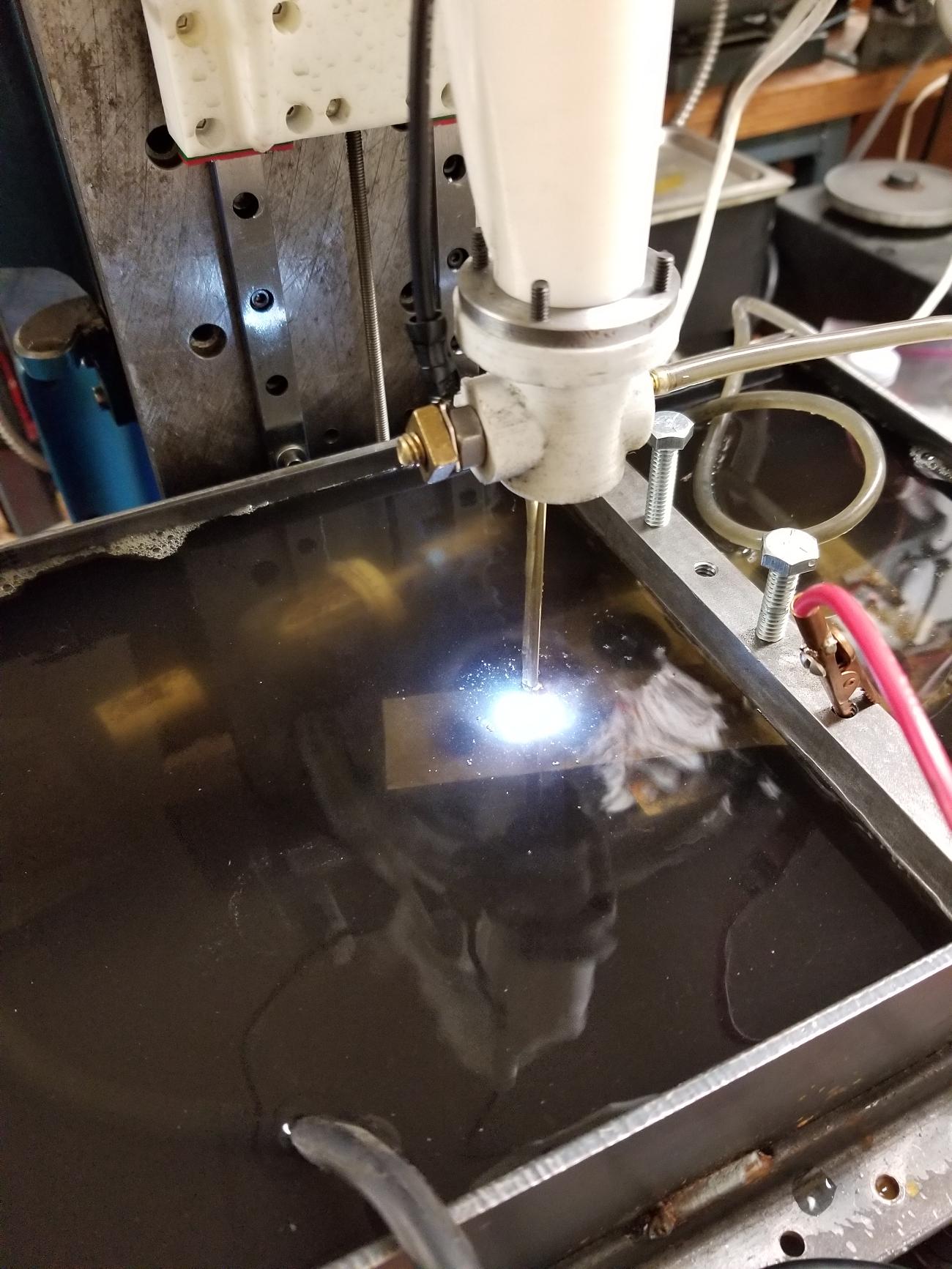

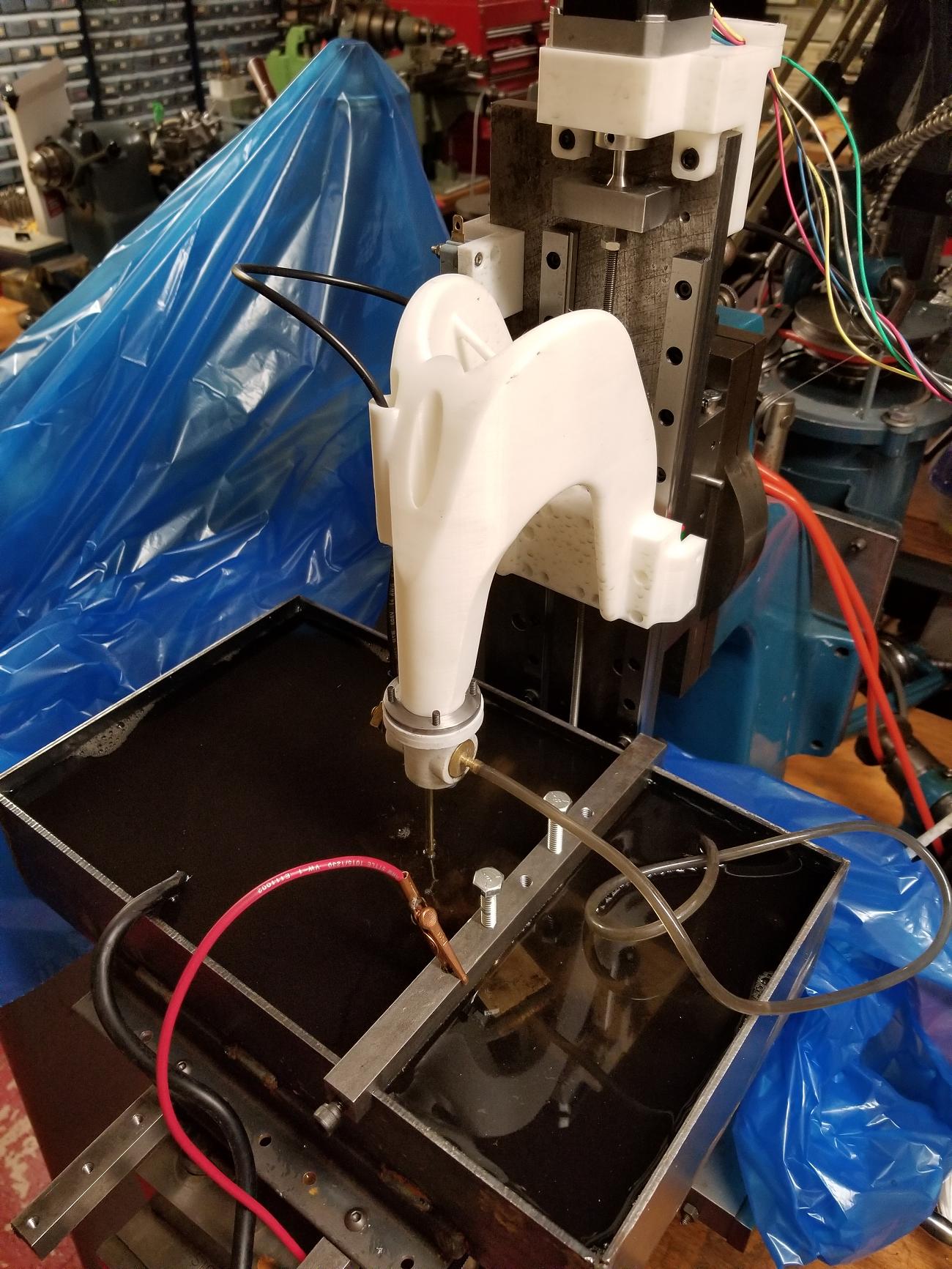

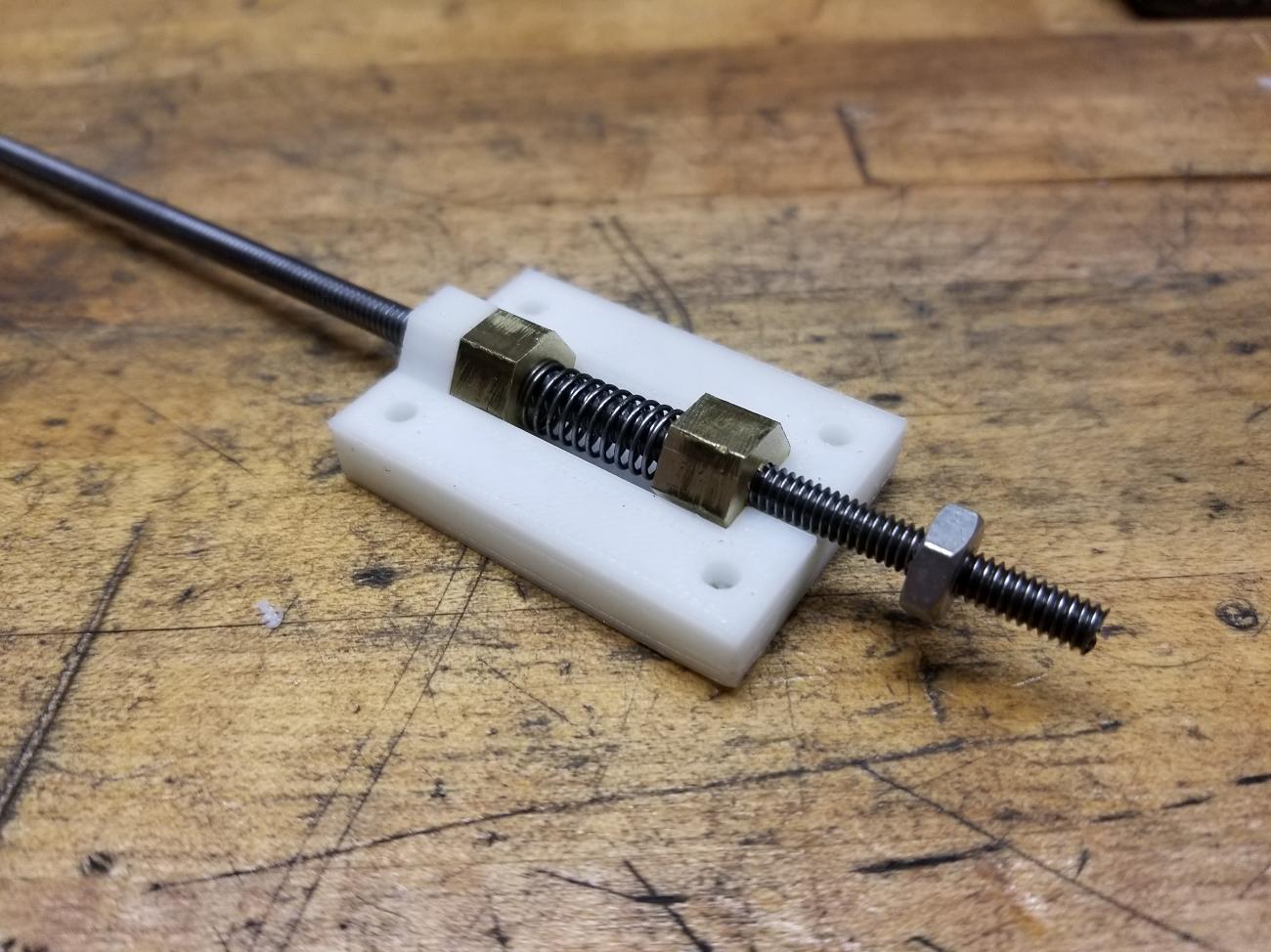

I bought at the Chris Bell auction his controller as per the Robert Langois sinker EDM design. Chris was part of a group local to Robert each of whom built one, I gather before the article as the very same controller below makes a cameo in the article. The mechanics are largely 3D printed. I thought I'd posted this before, you but you can;t search "EDM"! Never met Chris, but respect is workmanship a great deal.

The EDM works well enough and saved me once with a broken tap. Not having worked through the electronics, what did you guys find was lacking?

Its set up on my BCA jig borer, replaces the spindle and the tank sits on the table, Slab of cold rolled, 3D printed parts and some cheapo linears rails and I'm burnin' baby 😀

gerritv

Gerrit

Jaako Haguland, Plasmaboog and others from the start times of WEDM homebrew are all now using the BAXEDM generator. Jaako and Plasmaboog both had some success and improvements over the years but in the end I suppose they wanted to 'get on with it'. BAXEDM is really targeting retrofits though, of commercial machines that have antiquated or failed eletronics.

Plasmaboog started his journey in order to make/cross out wheels for model locomotives. Has some lovely examples of that.

there are plenty of research papers on what you need for pulse timing and shape, in the end it depends on whether you want speed as well as wire cutting. I am guessing that if/when I start, it will be a generator with variable pulse frequency and duty cycle for an initial kick at it.

and I echo the quality of Chris' workmanship. I have his UPT from that auction; beautifully made and a joy to use.

Plasmaboog started his journey in order to make/cross out wheels for model locomotives. Has some lovely examples of that.

there are plenty of research papers on what you need for pulse timing and shape, in the end it depends on whether you want speed as well as wire cutting. I am guessing that if/when I start, it will be a generator with variable pulse frequency and duty cycle for an initial kick at it.

and I echo the quality of Chris' workmanship. I have his UPT from that auction; beautifully made and a joy to use.

Canadium

Ian

This guy seems to get very interesting results without the BAXEDM

This guy gets some very cool results using the BAXEDM

Any one have one of these?

www.vevor.ca

www.vevor.ca

This guy gets some very cool results using the BAXEDM

Any one have one of these?

VEVOR Portable EDM Machine 800W EDM Tap Remover Depth Setting 0.039"-3.94" Tap Disintegrator Auto Shut-off EDM Remover 0.03"-0.39" Drill Drifts from Blind Hole Broken Taps Removal Machine for Taps | VEVOR CA

Shop VEVOR Portable EDM Machine 800W EDM Tap Remover Depth Setting 0.039"-3.94" Tap Disintegrator Auto Shut-off EDM Remover 0.03"-0.39" Drill Drifts from Blind Hole Broken Taps Removal Machine for Taps at lowest price, 2-day delivery, 30-day returns. Shop now at VEVOR.