Doggggboy

Ultra Member

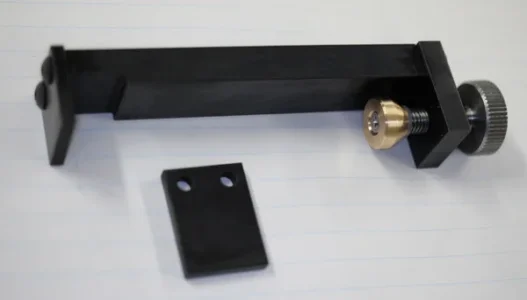

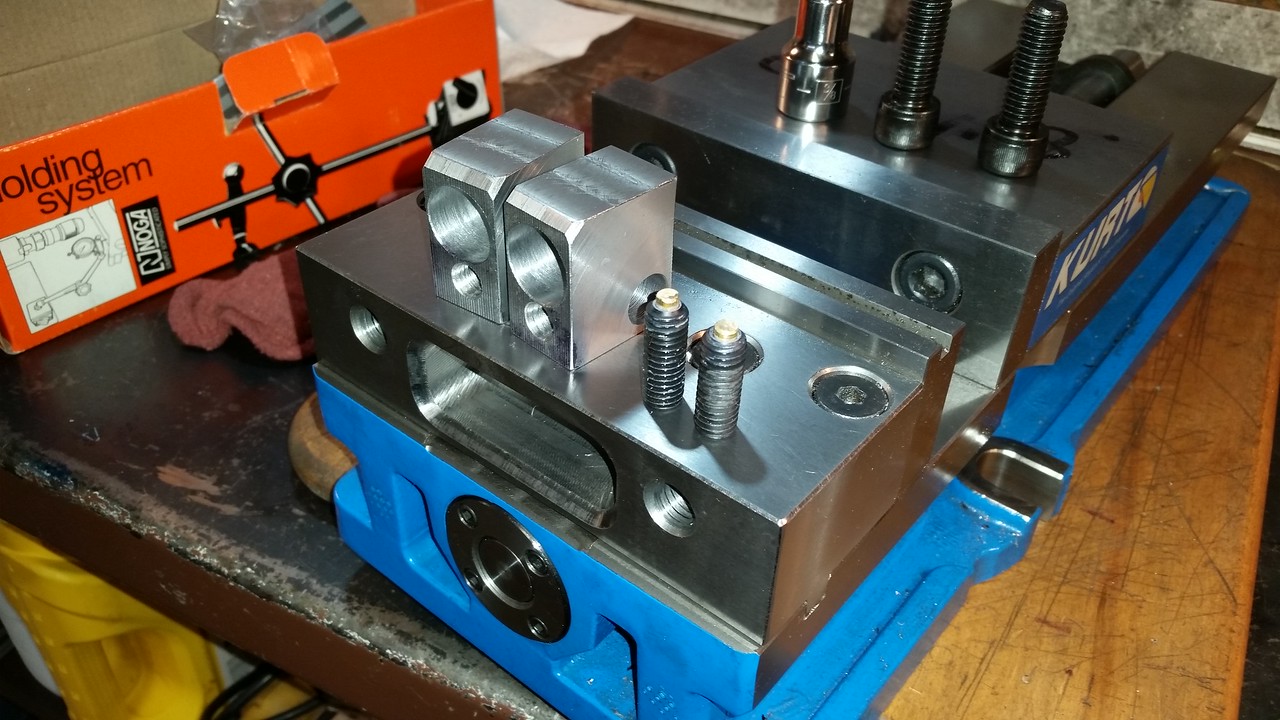

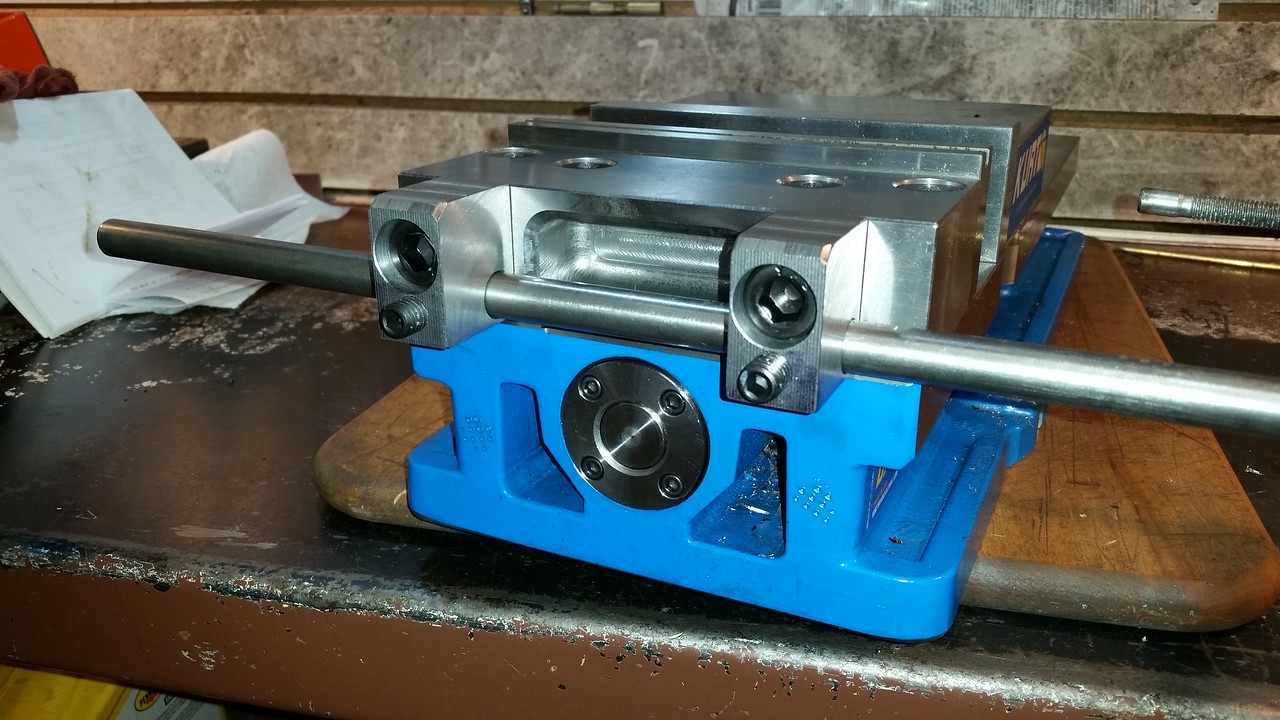

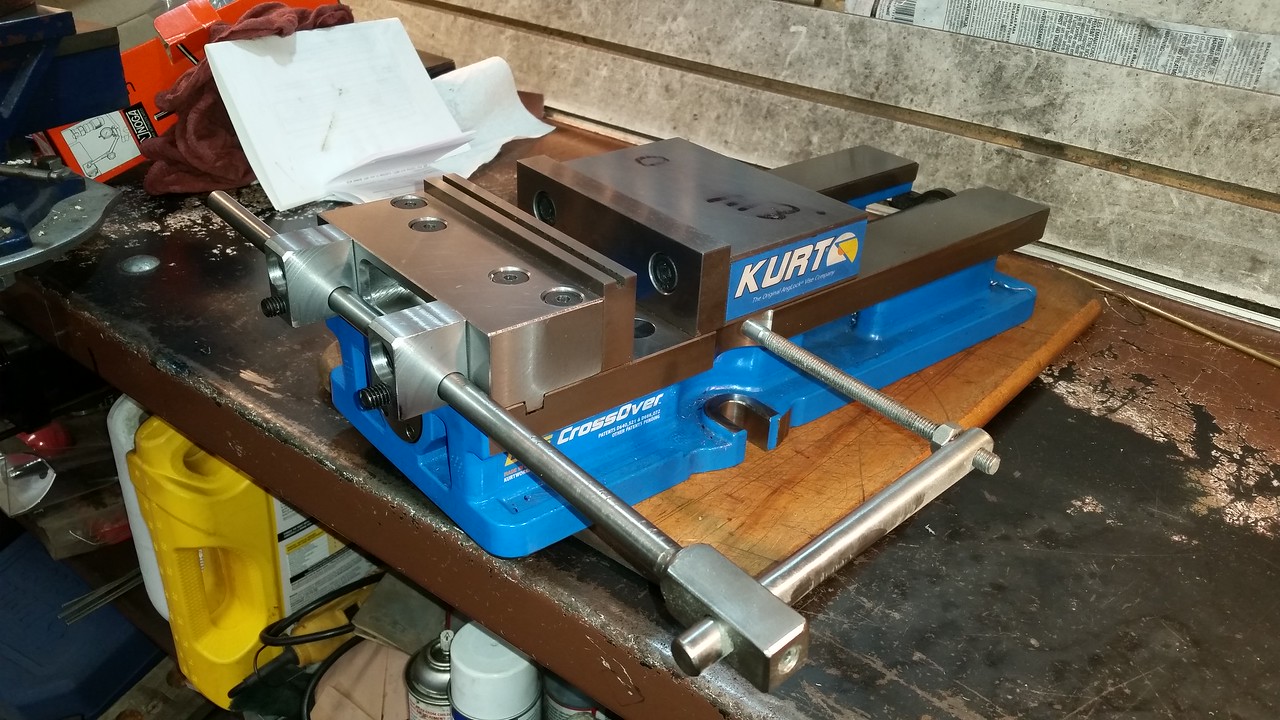

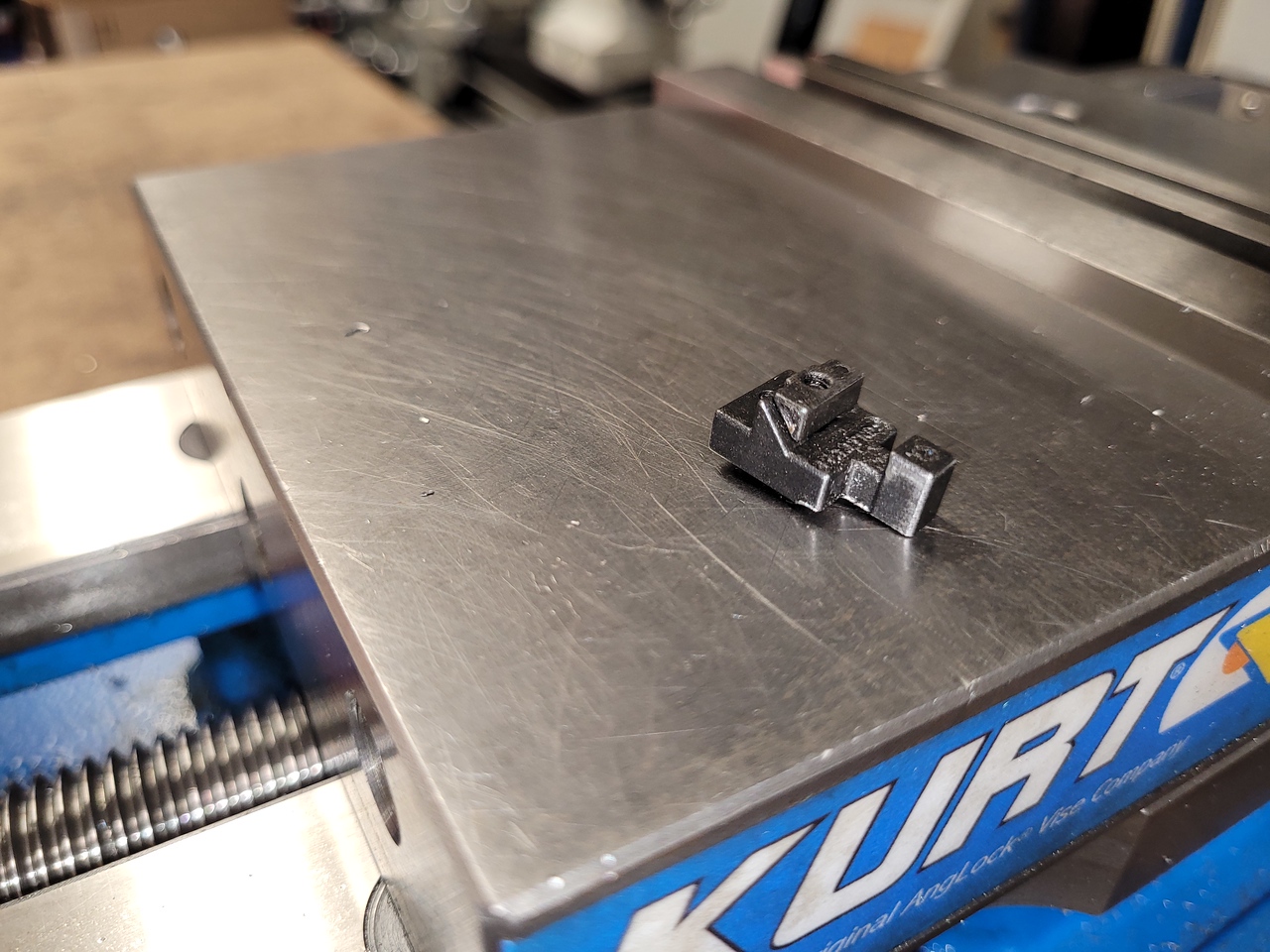

I 3d printed a speeder handle for the Kurt D6 Crossover vise and when I put it on I remembered watching a Joe Pie video showing the stop that came with his Kurt vise on his CNC setup. I had a quick look and sure enough. There is a little vise stop stuck in the end by the keeper for the screw.

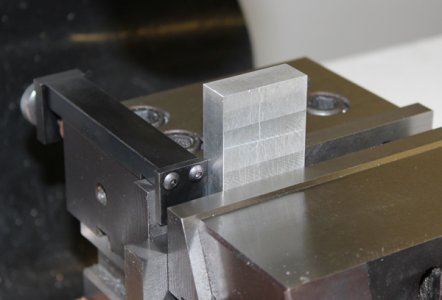

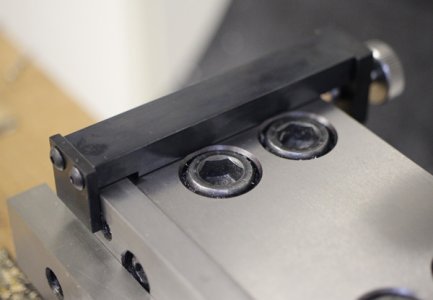

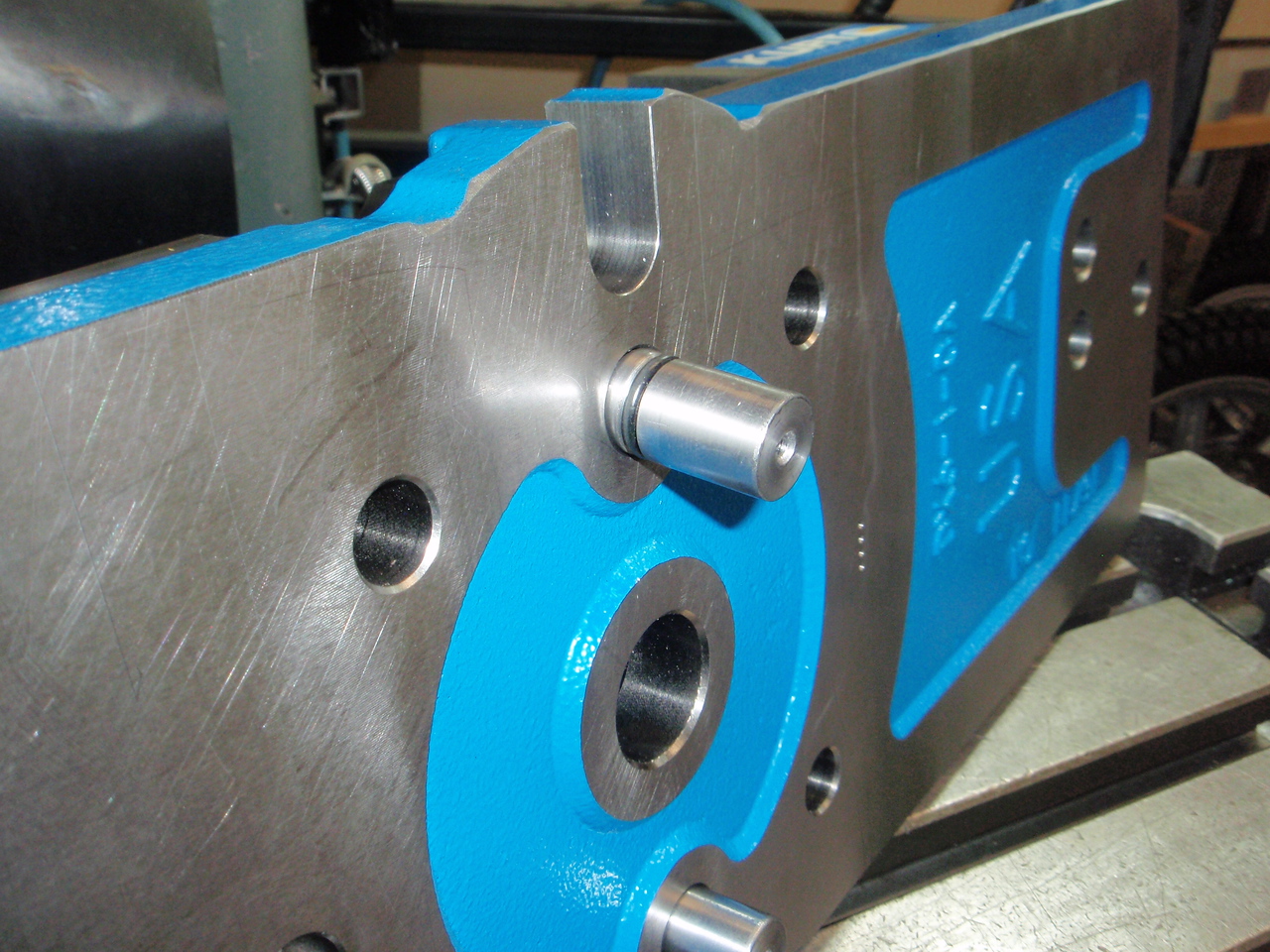

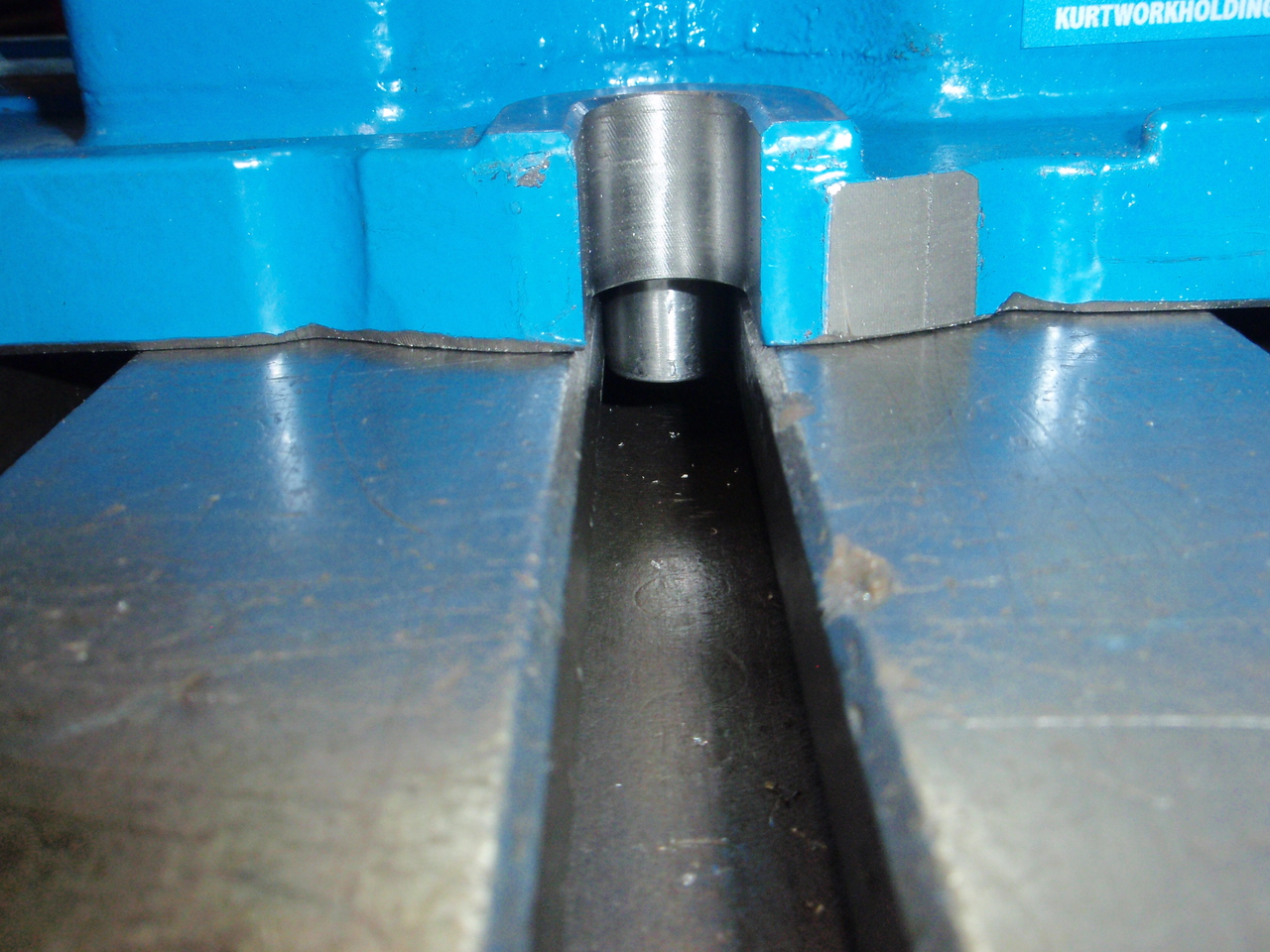

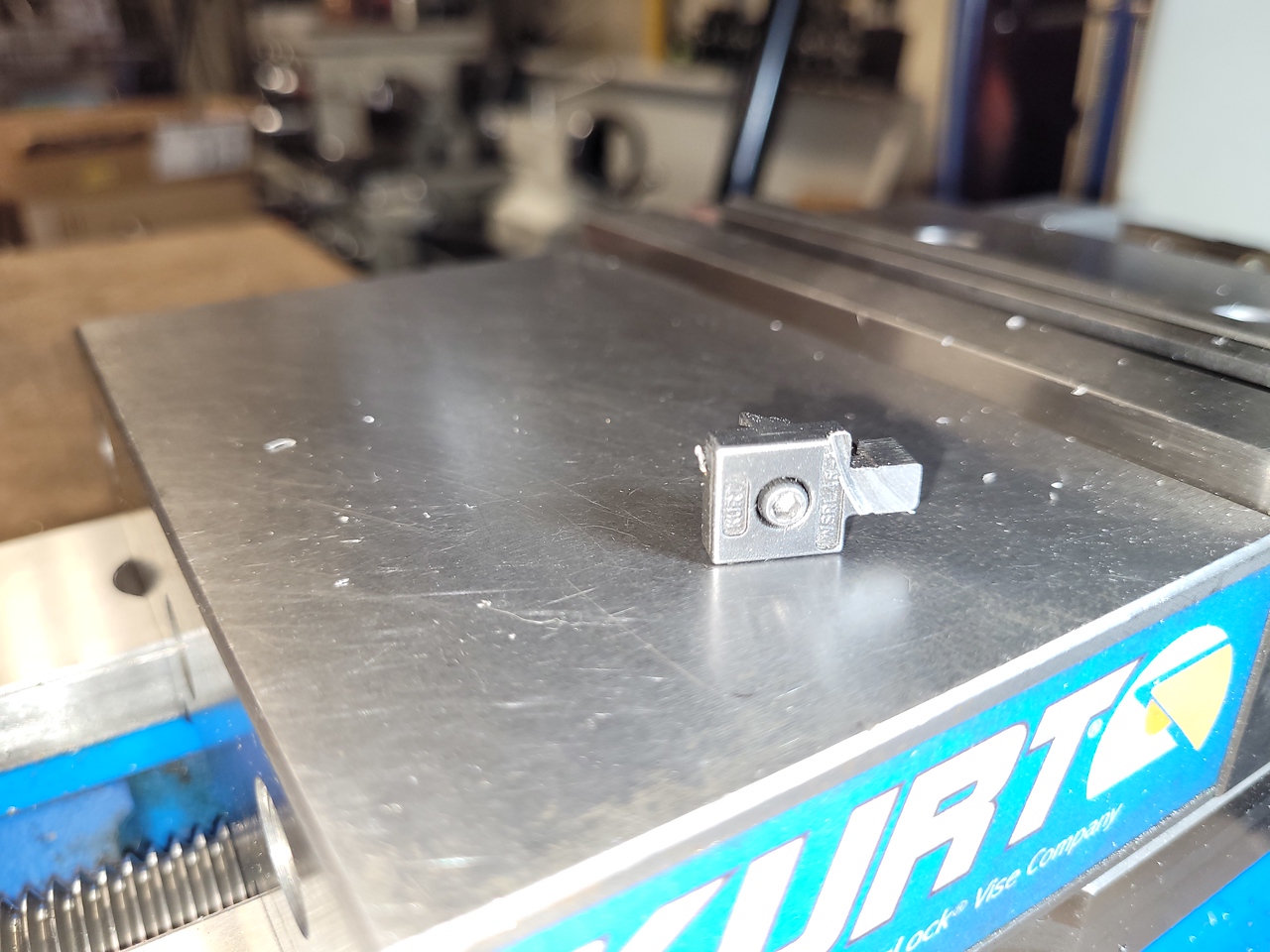

Fits nicely in the slot on the top of the jaw and uses a set screw to run the wedge into place to hold it.

I was on the brink of making one but now I can have a nap instead.

Fits nicely in the slot on the top of the jaw and uses a set screw to run the wedge into place to hold it.

I was on the brink of making one but now I can have a nap instead.