-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

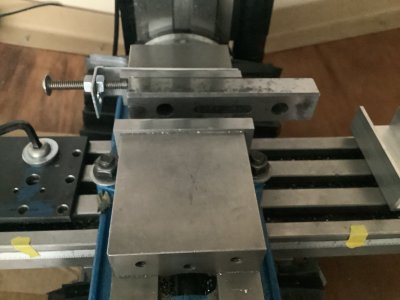

Product Vise Stop!

- Thread starter 1018Machine

- Start date

Product

A little cheaper on Aliexpress, https://vi.aliexpress.com/item/1005003518993184.html?gatewayAdapt=glo2vnm

Not w/ $29.95 shipping.A little cheaper on Aliexpress, https://vi.aliexpress.com/item/1005003518993184.html?gatewayAdapt=glo2vnm

Even cheaper....plus free shipping.....

https://vi.aliexpress.com/item/1005005611644368.html?gatewayAdapt=glo2vnm

but in Nylon. lol

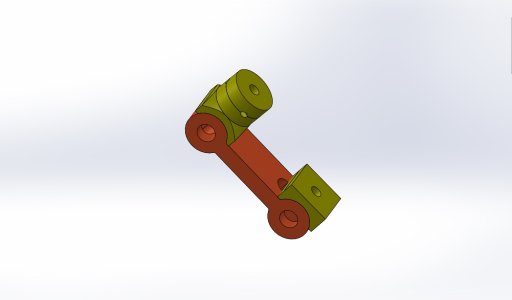

Should be able to model and 3D print these.

https://vi.aliexpress.com/item/1005005611644368.html?gatewayAdapt=glo2vnm

but in Nylon. lol

Should be able to model and 3D print these.

I did a quick search & found those, too. Thinking to myself, "Now these are less expensive!" Then the fine print revealed itself...but in Nylon. lol

Well I'm on hold for ordering things until we get back after our XMas escape. So anything that gets delivered during that time might sit on the porch for much of a day before a friend would pick it up. So I think, even though I want one, I'll wait. Don't really need it at the moment.

Although... want and need are two different things.

Although... want and need are two different things.

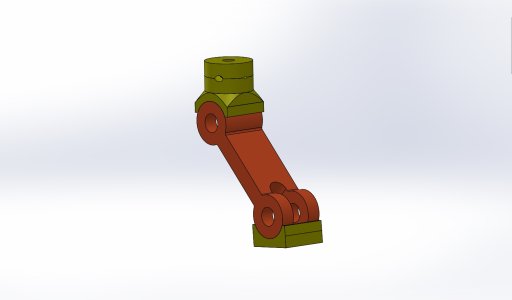

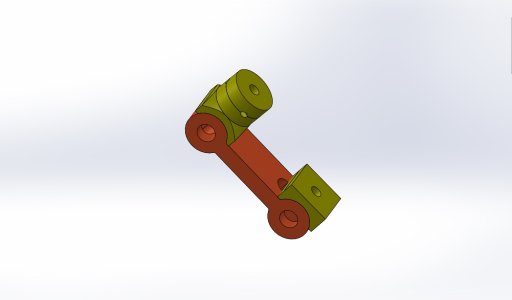

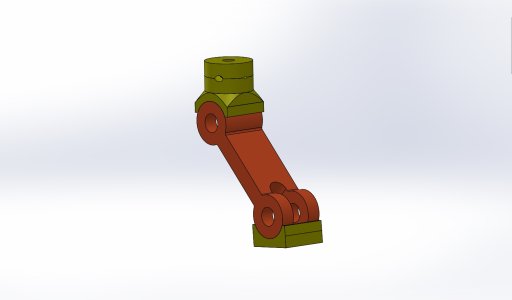

Looks close. I will try and print it. If it is good I'll post the files here.

It is set up for a 0.25" or a 0.125" rod. Made the holes large enough to handle a 10mm cap screw or a 3/8" cap screw.

Will need to make a 0.625" dia. threaded barrel nut and a 0.625" dia. barrel washer. (I thought about 3D printing the barrels but the thread might not stand up. Thought about 3D printing t-nut also.)

It is set up for a 0.25" or a 0.125" rod. Made the holes large enough to handle a 10mm cap screw or a 3/8" cap screw.

Will need to make a 0.625" dia. threaded barrel nut and a 0.625" dia. barrel washer. (I thought about 3D printing the barrels but the thread might not stand up. Thought about 3D printing t-nut also.)

MrWhoopee

Super User

Here's the one I use most of the time. Then there's the one that clamps on the jaw and the one that bolts to the table. You can never have too many.Vise Stops come in a lot of variations.

Mine bolts behind the fixed jaw and is easy to remove.

I still need to make one that has a step for the stepped jaws. Seems I'm always switching from step to parallels and having to switch stops.

The price of the one below is tempting - but it is a weak want (and not a need).

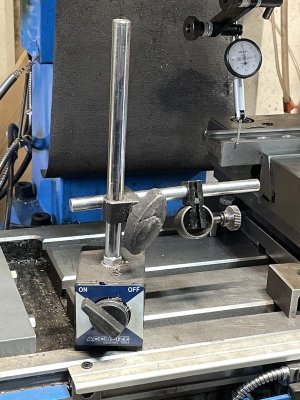

I park this spare indicator magnetic base at the back of the mill tray - it works well, no tools are needed, it is quick to adjust/place, and has a fine adjustment. (I bought a dial indicator from Accusize. The base arrived with a cosmetic crack/chip. I complained and they sent me a new one and said don't bother returning the damaged one. I repaired it and it is now my free vise stop).

(BTW- Accusize are great to deal with and for anyone that does not realize it - they give us CHMW members a 10% discount).

vi.aliexpress.com

vi.aliexpress.com

I park this spare indicator magnetic base at the back of the mill tray - it works well, no tools are needed, it is quick to adjust/place, and has a fine adjustment. (I bought a dial indicator from Accusize. The base arrived with a cosmetic crack/chip. I complained and they sent me a new one and said don't bother returning the damaged one. I repaired it and it is now my free vise stop).

(BTW- Accusize are great to deal with and for anyone that does not realize it - they give us CHMW members a 10% discount).

Universal Adjustable CNC Mill Machine Work Piece Stop Positioner for Lathe Workpiece Multi Function Milling Machine Locator Tool - AliExpress 1420

Smarter Shopping, Better Living! Aliexpress.com

KSFs: Wide adjustability and ease of movement.Here's the one I use most of the time. Then there's the one that clamps on the jaw and the one that bolts to the table. You can never have too many.

View attachment 56310

I still need to make one that has a step for the stepped jaws. Seems I'm always switching from step to parallels and having to switch stops.

Bravo !!

I spoke to a young lady last week at Accusize about the alleged discount. She knew nothing about it.they give us CHMW members a 10% discount

Ah. That was the issue. Thx.The code is for online

She did mention a 10% discount for first time customers. Don't imagine they can be combined, then.

Tom Kitta

Ultra Member

Here is cheapest steel one from ali for just $26 including shipping.

www.aliexpress.com

www.aliexpress.com

On same item basis Amazon has zero chance competing with aliexpress.

Universal Adjustable CNC Mill Machine Work Piece Stop Positioner for Lathe Workpiece Multi Function Milling Machine Locator Tool - AliExpress 202216001

Smarter Shopping, Better Living! Aliexpress.com

On same item basis Amazon has zero chance competing with aliexpress.

Looks better in real life.

5 pieces

I used PLA. 4 walls 20% grid infill

Tree supports for the bone.

If I did it again I would use a textured build plate for the red pieces. The smooth build plate makes for some slippery joints. It should tighten up ok, but a textured surface would be better,.

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

drive.google.com

Cheers,

5 pieces

I used PLA. 4 walls 20% grid infill

Tree supports for the bone.

If I did it again I would use a textured build plate for the red pieces. The smooth build plate makes for some slippery joints. It should tighten up ok, but a textured surface would be better,.

Bone.STL

drive.google.com

drive.google.com

TopHat.STL

drive.google.com

drive.google.com

top-collar.STL

drive.google.com

drive.google.com

BottomHat.STL

drive.google.com

drive.google.com

bottom-collar.STL

drive.google.com

drive.google.com

Cheers,