TorontoBuilder

Sapientia et Doctrina Stabilitas

I've worked out the mod for a duo grinder that combines the features of the Vevor 13A and 13B and I'd like to propose a group project for all members who are interested.

Below is the 13A innards (motor mount plate and the pivot) for the split point grinding.

Below are the 13B innards (motor mount plate and the pivot for web thinning.

I believed that the duo machines had to have their pivots moved to the middle of the motor mounting plate.

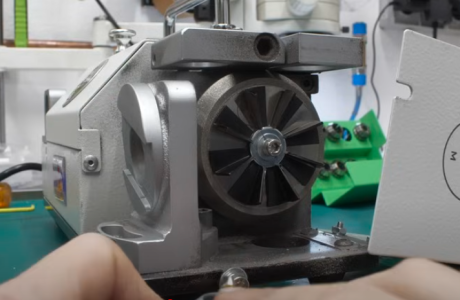

The motom appears to confirm that the web thinning pivot has been relocated to the mid point of the motor mount. It is hard to see how the split point jig portion is attached from this angle.

This angle isn't much help, but it does seem to confirm that the spring loaded depth adjustment is on the outbound side of the web thinning adapter.

This view suggests that the split point portion may be two sided spring loaded adjustment given the two holes.

There are many similar machines, set up for end mills, drills and such but with different methods of doing each bevel. Here is how one that I believe the duo grinder is based on... at least the pivot. Then the split point is affixed to a piece that it bolted on below and to the right of the pivot bolt.

So new motor mount plate, new split point plate and flange, new pivot mechanism and web thinning plate and brand new duo machine. I figure that the material will cost under $30. Maybe another $100 for a black oxide kit because I think I'm out of solution. About $50 for the ER25 collets to expand the grinding range up to 20mm

Below is the 13A innards (motor mount plate and the pivot) for the split point grinding.

Below are the 13B innards (motor mount plate and the pivot for web thinning.

I believed that the duo machines had to have their pivots moved to the middle of the motor mounting plate.

The motom appears to confirm that the web thinning pivot has been relocated to the mid point of the motor mount. It is hard to see how the split point jig portion is attached from this angle.

This angle isn't much help, but it does seem to confirm that the spring loaded depth adjustment is on the outbound side of the web thinning adapter.

This view suggests that the split point portion may be two sided spring loaded adjustment given the two holes.

There are many similar machines, set up for end mills, drills and such but with different methods of doing each bevel. Here is how one that I believe the duo grinder is based on... at least the pivot. Then the split point is affixed to a piece that it bolted on below and to the right of the pivot bolt.

So new motor mount plate, new split point plate and flange, new pivot mechanism and web thinning plate and brand new duo machine. I figure that the material will cost under $30. Maybe another $100 for a black oxide kit because I think I'm out of solution. About $50 for the ER25 collets to expand the grinding range up to 20mm

Attachments

Last edited by a moderator: