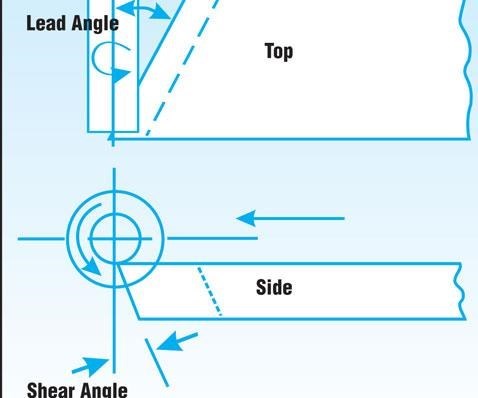

Experimenting with angles I've tried between10 degrees and 20 degrees from vertical. 10 seems to give a better finish and the edge needs to be razor sharp.

I got around to measuring one of my shear tools. As I expected, it looks like they are all 10 degrees plus/minus a degree and they all have a mild 5 degree back/end relief. I've tried lower back reliefs but they seem to catch swarf once in a while with a mild effect on finish. Too much and the edge seems to dull faster. I ended up at around 5.

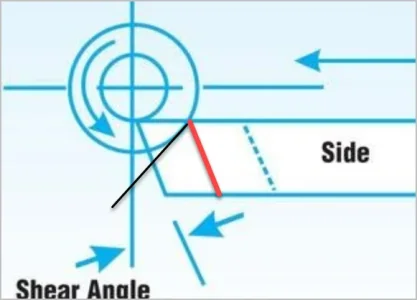

Here is one to show what my typical grind looks like. Please ignore what looks like a chip breaker - it's actually an artifact of a previous grind. No point in chip breakers on a shear tool.