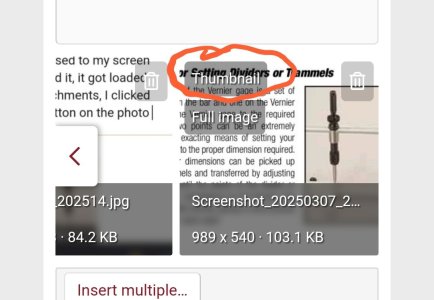

After looking at the Starrett manual" Tool and rules" that Chazz linked in his post in “Little Machine Shop Special of the Week:”

https://qqp.mypresswise.com/user/images/STARRETT/Starrett Tools and Rules (Bulletin 1211).pdf

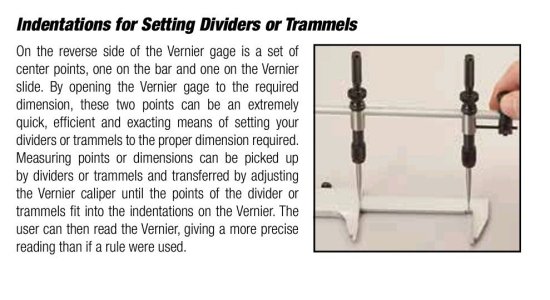

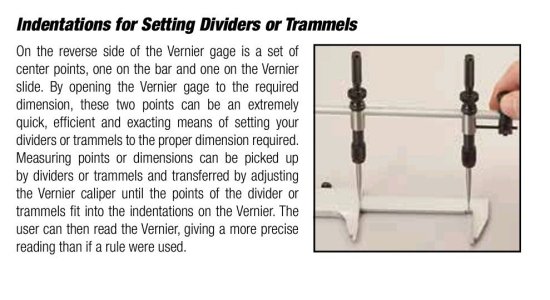

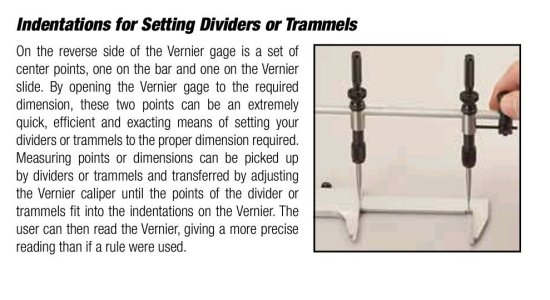

They showed a vernier caliper with the two dimples to measure a divider or trammel. I thought I should do that. Then Whydontu posted how simple it would be to do, again I thought I should to that. So last night standing in front of my workbench looking at my caliper, I said to myself lets do it!!

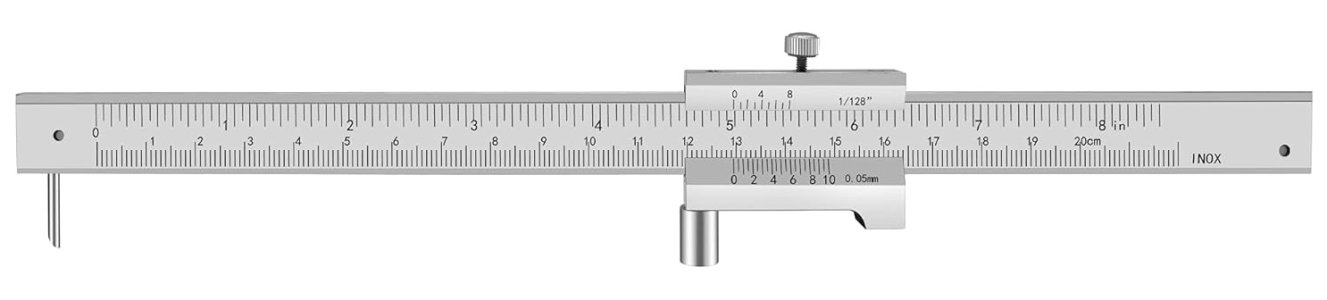

-Set the caliper at 200" ( 5.08mm) and locked the screw.

-Mounted the caliper on my dyi pallet, shimmed were needed and then clamped it down.

-Found the center of the jaws with an edge finder.

-moved over .200" and center drilled a dimple, repeat for the other side. Done

One caliper was super easy to drill dimples, the other my center drill bounce off the surface, I had to switch over to a 1mm carbide drill to get it done.

I like these super simple little project which adds another measuring option when needed.

https://qqp.mypresswise.com/user/images/STARRETT/Starrett Tools and Rules (Bulletin 1211).pdf

They showed a vernier caliper with the two dimples to measure a divider or trammel. I thought I should do that. Then Whydontu posted how simple it would be to do, again I thought I should to that. So last night standing in front of my workbench looking at my caliper, I said to myself lets do it!!

-Set the caliper at 200" ( 5.08mm) and locked the screw.

-Mounted the caliper on my dyi pallet, shimmed were needed and then clamped it down.

-Found the center of the jaws with an edge finder.

-moved over .200" and center drilled a dimple, repeat for the other side. Done

One caliper was super easy to drill dimples, the other my center drill bounce off the surface, I had to switch over to a 1mm carbide drill to get it done.

I like these super simple little project which adds another measuring option when needed.

Attachments

Last edited by a moderator: