I'm sure others are more expert in this than me, but here is my take - copied and edited from something I shared with a few local club members about buying cheap import carbide for the home shop - bolded is relevant to the question at hand.

Insert nomenclature is covered by an ISO standard(metric), and an ANSI standard (inch). Here's my understanding / short explanation of some of the important features to us (i.e. hobby machinists). Be careful – the US ANSI B212 nomenclature is very similar to the ISO one but can cause confusion as what may be a 09 (meaning 9mm) in ISO is 3 for ANSI (meaning 3/8”). I'll stick to the ISO as its what the Asian suppliers tend to use..(no guarantees).

The holder obviously dictates a few parameters of the insert, such as its cutting length (size) and thickness, side clearance angle and shape but we still have a few more items to decide on.

The first letter of the code for the insert is the shape, so match this to the holder. (C,D,R, T or V)

The second letter is the side clearance – again match to the holder (usually C)

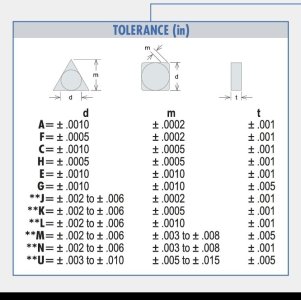

Third letter is the “tolerances”. This is one where we get to pick features of the insert that may differ from one insert to another for the same tool holder.

I refer to this as the “finish” of the insert even though its indicated as the tolerance. This has a lot to do with how sharp the cutting edge is.

An insert that is sold / marketed as being for non-ferrous metals or aluminum specifically usually has a very sharp cutting edge and a mirror like finish without any coating. It will almost always be identified with a G in the 3rd letter position of the insert name (ie DCGT CCGT VCGT etc.).

The letter M is often used to designate the insert is “as molded” in the third letter position. This means that the cutting edge has a very slight radius to it, and is usually marketed to be used on ferrous (steel) and the like, and also very often has a coating applied (TiN, or some other PVD coating). In the home shop they are great for steel, but realize that they aren't great for finishing with a very light cut. They prefer a cut of at least some depth due to the less sharp edge.

To cut to the chase - for an aluminum cutting insert, look for CCGT - the G in the "tolerance" position means "ground" finish and will be very sharp.

One last new caveat - I don't know if the ISO and ANSI inserts are interchangeable - they may not be - i.e. 9mm is not exactly 3/8" - so if you know your holders are made with ISO standards I'd stick to ISO inserts.