Dan Dubeau

Ultra Member

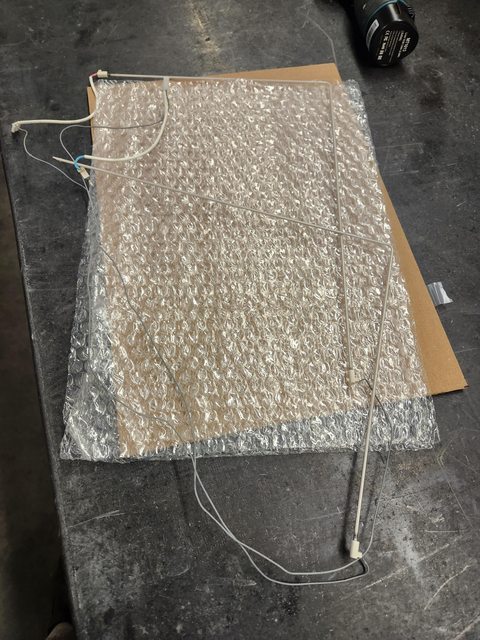

Greeted this morning with a z axis drive fault in our Haas VF2. Spent some time diagnosing that, and swapping servo amps to isolate the problem and save a service call, then the screen on the VF5 went black, so I spent some time digging around and figured it was just the LCD backlights that went out. Haas wants $1000 for the entire screen assembly, but I found just the backlights for $77. Still waiting on a quote for the servo amp, but I'm guessing around $1000-1200 from the last one I swapped last year in the vf5.

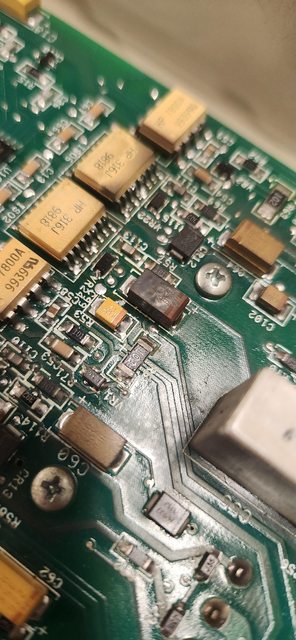

We used to have a guy that rebuilt them 10 ish years ago, but he's no longer in business. Would love to find another, or be knowledgeable enough to do it myself but I'm not quite there in my electronics knowledge yet to be confident enough to not fry someone elses machine......If it were mine, sure I'd roll the dice and poke around. There are some caps on the board that look like they got pretty warm....It's 23 years old.....If I had to guess just by looking at it, I'd start there and see what else got fried when they did.

VF5 still works, but it's pain holding a flashlight up close to see the #'s. Luckily muscle memory lets me move around the menus pretty good blindly, but for the onsee twosee stuff I'm doing right now it's a pita. It's funny how much of it is simple repetition though. Got through the entire power on, door lock disable, and homing routine with warmup first try with no light lol.

Had such a good productive weekend too. ha.

We used to have a guy that rebuilt them 10 ish years ago, but he's no longer in business. Would love to find another, or be knowledgeable enough to do it myself but I'm not quite there in my electronics knowledge yet to be confident enough to not fry someone elses machine......If it were mine, sure I'd roll the dice and poke around. There are some caps on the board that look like they got pretty warm....It's 23 years old.....If I had to guess just by looking at it, I'd start there and see what else got fried when they did.

VF5 still works, but it's pain holding a flashlight up close to see the #'s. Luckily muscle memory lets me move around the menus pretty good blindly, but for the onsee twosee stuff I'm doing right now it's a pita. It's funny how much of it is simple repetition though. Got through the entire power on, door lock disable, and homing routine with warmup first try with no light lol.

Had such a good productive weekend too. ha.