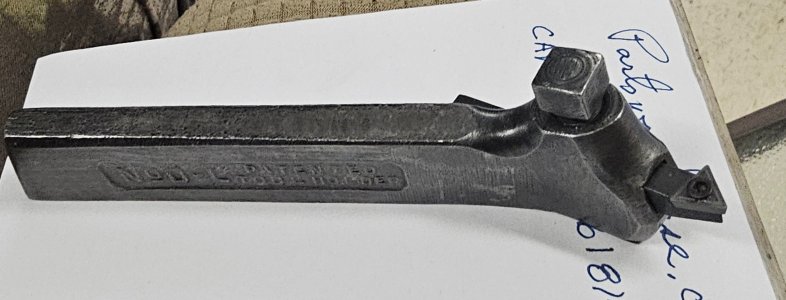

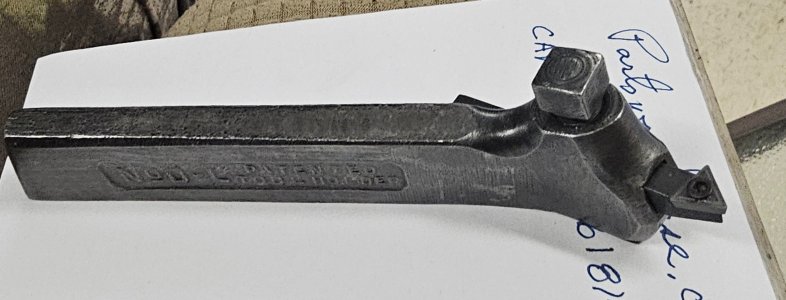

My new AMMCO Shaper has a size 0 lantern tool post on it. I plan to investigate ways to install an improved toolpost with emphasis on the one that @140mower developed. But in the meantime, it seems prudent to get a few tool holders to fit the current lantern tool post. It came with 1 lonely Left Armstrong tool holder for 1/4" bits.

I've been trying to find a right and a center tool holder for 1/4" tool bits. So far I've only found a few beat up holders on e-bay. Nothing on Amazon, Kijiji, or AliExpress. Nothing using Google either.

Does anyone know a source for such things?

I've been trying to find a right and a center tool holder for 1/4" tool bits. So far I've only found a few beat up holders on e-bay. Nothing on Amazon, Kijiji, or AliExpress. Nothing using Google either.

Does anyone know a source for such things?