Hollow-Grind

Member

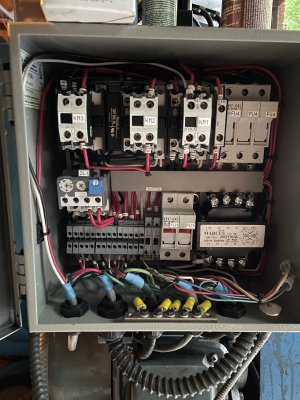

Working on setting up my diy phase converter. Legs are balanced. Pony runs smooth. The issue I am tracking down is the thermal overload relay tripping. It now takes about 3 mins to trip and cut power to the machines and used to trip out in 30 seconds or less.

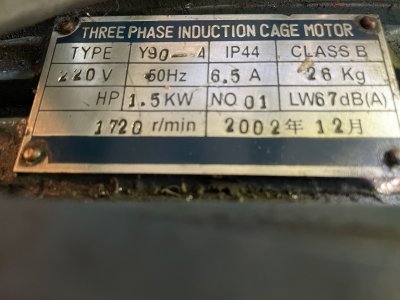

I will assume the relay is stock. It only adjusts to 4amps but motor FLA is 6.5 amps. I do not own a clamp on meter yet but may have to buy one. The motor is 3 phase and claims 2kw but says HP so either 2 or 2.5 hp. Pony is 5hp.

Should the thermal overload relay not be sized bigger? Does anyone know running amps of a 2hp 3phase motor not under full load? This lathe came from a school and I did find loose wiring in some spots. Could this be wiring gremlins? The twist lock plus seems kinda loose and wonder is current loss could be there?

I will assume the relay is stock. It only adjusts to 4amps but motor FLA is 6.5 amps. I do not own a clamp on meter yet but may have to buy one. The motor is 3 phase and claims 2kw but says HP so either 2 or 2.5 hp. Pony is 5hp.

Should the thermal overload relay not be sized bigger? Does anyone know running amps of a 2hp 3phase motor not under full load? This lathe came from a school and I did find loose wiring in some spots. Could this be wiring gremlins? The twist lock plus seems kinda loose and wonder is current loss could be there?

Attachments

Last edited: