OK, so that’s a play on words. It is my first mill but it’s also a First LC1 – ½ TM (Long Chang, out of Taiwan).

A few weeks ago I saw an ad for machine shop equipment for sale (and in my back yard for a change) so I went to have a look and with a few twists & turns I had a deal for the mill.

The machine is a step drive version and as it turns out it’s 2 HP and surprisingly wired for 110/220 single phase. So much for the idea of playing around with a VFD! It was bought new in 1987 by a one man machine shop with a “gun customizing” business so it wasn’t as heavily used as a production shop. He also had a lathe, surface grinder and some other gear to occupy his time. Anyone interested in a K. O. Lee surface grinder?

There’s some visible wear in the flaking of the Y-axis but the end play is only .045 on the X and .020 on the Y with little variation end to end so all good indications. It also has an X-axis power feed, a coolant pump and by my eye has a 4” riser on the pedestal.

Everything works and generally looks to be a good machine but needs some TLC to get the grunge off.

It comes with a drill press vise(!), a Vertex dividing head, 3 jaw (Burnerd) & 4 jaw chucks (with no obvious means of mounting, probably missing something), no backing plates, a boring head, fly cutting tools, a Rohm R8 keyed chuck, a few ER collets, a hold down kit & a bunch of misc. slitter and slot cutting tools. Basically I think the family wants to clear out the shop. The bonus is I got the Illustrated Parts Catalog and I'm supposed to get the manual which I haven't been able to find on the web.

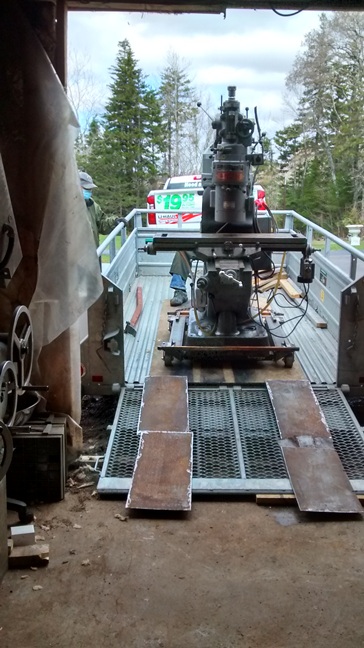

So, there it is until Saturday when the move happens. I’ve decided to rent a U-Drive pickup and one of their dual axle trailers with a ramp. Thinking about Dabbler’s advice I scouted out the trailer on the weekend and decided that it would do. The two I looked at had a plethora of reasonably robust looking tie down loops and the trailer looks like it could transport a tank let alone something as light as a mill!

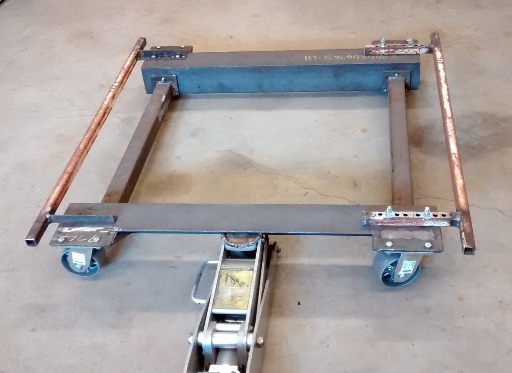

The bed is heavy corrugated metal over what look like plenty of 2 x 3 x ¼ tubes. The corrugated metal will play heck with the castors so I’ll put down a piece of plywood or maybe plate and I’ll have to protect the ramps with some plate because they’re only expanded grate but I have the plate so that’s not a big deal. I’ll plan to tilt the trailer with the jack or run the back wheels of the truck up on ramps or both to get a nice slope up the ramp although the trailer is actually quite low by itself.

The dolly should roll up and down that nicely and once it’s in the trailer I’ll jack it up and block it up on wood for the trip.

I'll post some photos when I figure out what's with my hosting provider.

D

Edit: I meant to add that I'll continue the thread as I bring the machine home and come up to speed with it so it'll be a living thread.

A few weeks ago I saw an ad for machine shop equipment for sale (and in my back yard for a change) so I went to have a look and with a few twists & turns I had a deal for the mill.

The machine is a step drive version and as it turns out it’s 2 HP and surprisingly wired for 110/220 single phase. So much for the idea of playing around with a VFD! It was bought new in 1987 by a one man machine shop with a “gun customizing” business so it wasn’t as heavily used as a production shop. He also had a lathe, surface grinder and some other gear to occupy his time. Anyone interested in a K. O. Lee surface grinder?

There’s some visible wear in the flaking of the Y-axis but the end play is only .045 on the X and .020 on the Y with little variation end to end so all good indications. It also has an X-axis power feed, a coolant pump and by my eye has a 4” riser on the pedestal.

Everything works and generally looks to be a good machine but needs some TLC to get the grunge off.

It comes with a drill press vise(!), a Vertex dividing head, 3 jaw (Burnerd) & 4 jaw chucks (with no obvious means of mounting, probably missing something), no backing plates, a boring head, fly cutting tools, a Rohm R8 keyed chuck, a few ER collets, a hold down kit & a bunch of misc. slitter and slot cutting tools. Basically I think the family wants to clear out the shop. The bonus is I got the Illustrated Parts Catalog and I'm supposed to get the manual which I haven't been able to find on the web.

So, there it is until Saturday when the move happens. I’ve decided to rent a U-Drive pickup and one of their dual axle trailers with a ramp. Thinking about Dabbler’s advice I scouted out the trailer on the weekend and decided that it would do. The two I looked at had a plethora of reasonably robust looking tie down loops and the trailer looks like it could transport a tank let alone something as light as a mill!

The bed is heavy corrugated metal over what look like plenty of 2 x 3 x ¼ tubes. The corrugated metal will play heck with the castors so I’ll put down a piece of plywood or maybe plate and I’ll have to protect the ramps with some plate because they’re only expanded grate but I have the plate so that’s not a big deal. I’ll plan to tilt the trailer with the jack or run the back wheels of the truck up on ramps or both to get a nice slope up the ramp although the trailer is actually quite low by itself.

The dolly should roll up and down that nicely and once it’s in the trailer I’ll jack it up and block it up on wood for the trip.

I'll post some photos when I figure out what's with my hosting provider.

D

Edit: I meant to add that I'll continue the thread as I bring the machine home and come up to speed with it so it'll be a living thread.

Last edited: