Sure! Why not! We all learn from healthy discussions like this.

I am probably talking about effects that are too small to cause the observed problems, and here are a few things that might better belong in the other thread, but since I am encouraged to spew ...

I believe in my heart of hearts that this is true. I'm no big time lathe repair shop, but I've aligned a few lathes quite successfully using my own approach. What I can tell you with confidence is that you are right - there is no such thing as a perfect spindle. Nor is there a perfect measuring tool. We humans have never figured out how to measure zero.

The OP's problem is big enough to measure reliably within the limits of what can be measured reliably.

That said, I think it helps to be able to recognize what can be improved upon and what is too little to worry about. It also helps to have an idea of the kind of precision you can expect from the various kinds of lathes available. A top notch precision lathe will usually run circles around a clapped out machine no matter how good it once was, and it will usually out run a hobby lathe and tool room lathe. Our expectations must be reasonable for the machine we are considering.

First, there really isn't such a thing as a single spindle axis. No matter how good the bearings, there will always be _some_ level of eccentricity.

Yup. You are correct. See also above about reasonable expectations.

I think the OP's measured taper is worse than I'd expect his machine to produce. Also, because it is taper (not runout), I think it can probably be improved. But there will be a limit beyond which further attempts to refine it are futile.

And since we assume ball or roller bearings, that eccentricity will be of a special kind - it will cycle around the notional center with a period proportional to the size of those balls / rollers to the other parts of the bearing.

Yes, I'd expect some level of eccentricity too. I don't know if it's period would be proportional to the size of the balls/rollers to the rest of the bearing. I'd have to see an analysis of that to get any sense of comfort about that.

Second between mounting plate, the chuck itself and the way it grips the work, some degree of eccentricity is assured.

Yes, but it isn't normally at a level that needs to be worried about. If it is, then it's time to accept it for what it is or do something about it. On my lathe, it's less than a tenth. I'm quite happy with it and have no desire to try and fix it.

Unless the machine is really bad, the largest source is probably user error (chucking the work at an angle).

This is where we fell off before. It doesn't matter if the work is chucked at an angle. After turning, the axis of the final product will be concentric with the axis of the spindle - assuming it is solidly held, is short enough to not droop measureably, and the part is never removed from the chuck till the work is complete. Yes, the stub held in the chuck will not be aligned with the rest of the work, but we are not going to reverse the part or use the stub in any way. And yes, it will have some eccentricity, but not enough to worry about.

These two factors alone will produce a series of spiral shaped ellipses in the work. If enough cuts are taken at speed x feed rates that aren't natural multiples of those other rates, the work should become round along an _effective_ axis of rotation.

I don't know about a spiral being the result. I've never seen that happen. If it does happen, it's at a level that I can't see or measure. I've done this enough times to know that it's not something I'd worry about.

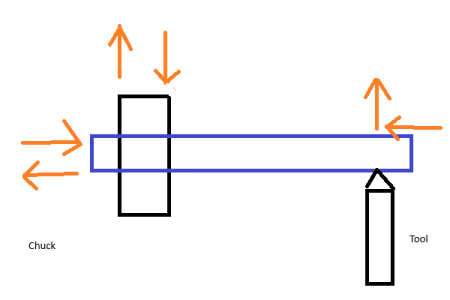

But there is another factor that will produce the taper of my imagination (tm). And that depends more on the direction of feed. Feeding away from the chuck will be much more resilient (2/3 more theoretically) than feeding towards the chuck. And that relates to to tool pressure versus the slenderness ratio of the work. No matter how stiff the material, or how light the cut, some lateral pressure will be exerted on the work by the tool. If the material does not remain in the elastic range, then it will simply break. but if it does, then it will reliably make a taper that grows larger the further away from the chuck that the tool goes. In the ranges quoted in this thread it may by microns

You should re-read your own thread about cribbage pegs.

All of what you say can happen but there are ways to reduce the chances and the level of impact. In my experience the impact is neglidgeable. It might not be on a worn out machine or one with bad bearings.

About all I can say for sure is that every lathe I have aligned worked out well within reasonable limits.

With a perfect chuck, the reaction forces will be 4 times greater with an unsupported work piece versus one supported with a tail stock. An imperfect chuck will have higher forces on some jaws and some parts of each jaw - which will make everything worse. I thought I had an idea of a way that a poor chuck could cause microns turn into tenths or maybe even thou, but I totally doubt what I was saying before

probably I am way over thinking this, but I don't think I have ever been happy with the Hogan's Hero's line - I know nothing. I want to know. And mistakes are a great way to learn 😉

Ya, I agree that you are over thinking this as it relates to the OPs concerns.

Some might say who cares beyond that. Personally, I don't think for one minute that you are overthinking it with respect to understanding what could happen under other circumstances as well as exploring the theoretical limits of what is practical and achievable.

Sometimes it's worth it to set up a series of experiments to explore such things. If you do, I'd be keenly interested in following along.

Most of my experiments of this nature have been done while aligning a lathe. Especially comparing various methods others have used. When the dust settled, I have ended up settling on the dumbbell bar as the best method (for me) for minimizing unintentional tapers.

I am also slowly working away at improving my methods and I have an unfinished project on an improved dumb bell.