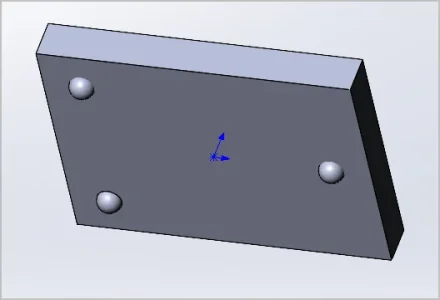

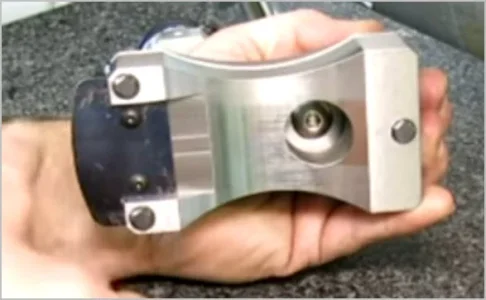

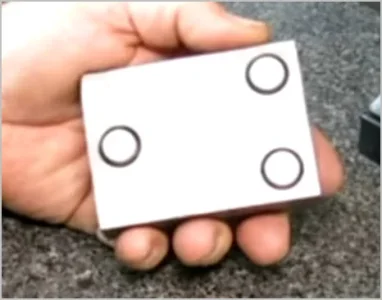

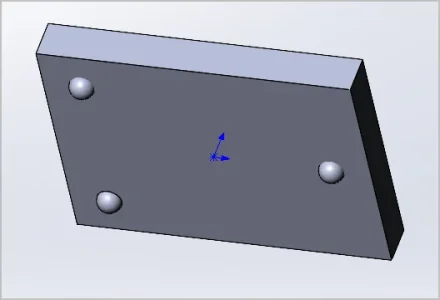

I was thinking of making a sliding measurement device for use on granite plate using 3-point contact using bearing balls, as opposed to lapping / scraping / pocket relieving the plate bottom surface.

So, mill the ball cavities with ball EM, insert balls, secure with Loctite... something like that. Then I got thinking, balls are quite hard, it would be a tangent point contact, maybe that is not so great for the granite. Potential for scour lines as opposed to spreading out over larger area. Are bearing balls considered bad Ju-Ju for surface plates?

So, mill the ball cavities with ball EM, insert balls, secure with Loctite... something like that. Then I got thinking, balls are quite hard, it would be a tangent point contact, maybe that is not so great for the granite. Potential for scour lines as opposed to spreading out over larger area. Are bearing balls considered bad Ju-Ju for surface plates?