140mower

Don

I thought that rather than plug up @David_R8 's shenanigans thread I would bring what little I know over to a place of it's own.....

To be honest, I have not used them yet, I first spotted them on Craigslist when I was making the gear cutting attachment for the shaper, but were priced out of my range. Fast forward about a year and they had come down in price to something I figured I could deal with should SWMBO find out. By then, I had made my gear and it was merrily going roundy round inside the feedbox in my lathe.....

HOWEVER! He says with a finger pointed to the sky, making little circles....... I have a book, and the book tells me that it's used for measuring gear tooth thickness at the pitch line.

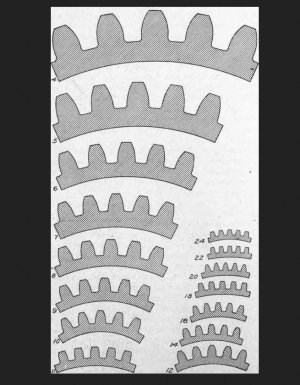

Last two images are courtesy of the book "Precision Measurement in the Metal Working Industry"

To be honest, I have not used them yet, I first spotted them on Craigslist when I was making the gear cutting attachment for the shaper, but were priced out of my range. Fast forward about a year and they had come down in price to something I figured I could deal with should SWMBO find out. By then, I had made my gear and it was merrily going roundy round inside the feedbox in my lathe.....

HOWEVER! He says with a finger pointed to the sky, making little circles....... I have a book, and the book tells me that it's used for measuring gear tooth thickness at the pitch line.

Last two images are courtesy of the book "Precision Measurement in the Metal Working Industry"